Over the past decade, adenoassociated virus (AAV) vectors have become established as leading gene-delivery vehicles. In 2017, the pipeline for gene therapies included 351 drugs in clinical trials and 316 in preclinical development (1–4). As those candidates advance, significant efforts are being made in process development and manufacturing for viral vectors, with the overall goal of reducing process impurities while maintaining the highest possible process yield. To address that goal, industry suppliers have developed innovative AAV-specific separation technologies. Thermo Fisher…

Search Results for: antibody characterization

HCP Assay Development: Managing Risks with Evolving Technologies

Host-cell proteins (HCPs) are major impurities of concern in biomanufacturing. When present in drug formulations, they can reduce efficacy (by compromising product stability), introduce toxicity, and increase a recipient’s risk for long-term immunogenicity. Understanding HCP profiles and integrating effective removal strategies are important parts of developing new biological drugs — to fulfill regulatory guidelines and to ensure patient safety through product quality. HCP populations can be both complex and structurally diverse, and some changes in upstream culture conditions can affect…

Stability Testing: Monitoring Biological Product Quality Over Time

Many physical and chemical factors can affect the quality, safety, and efficacy of biopharmaceutical products, particularly after long-term storage in a container–closure system that can be subject to variations in temperature and light, as well as agitation with shipping and handling. Proteins are inherently complex physiochemically, from their primary amino acid sequences to their higher-order structures, and they require specific conditions to maintain their integrity and functionality. Advanced biological therapies can be even more complicated and particular about their environments.…

Emerging Strategies for Drug Product Comparability and Process Validation: Part 1 — Analytical Tools and Drug Product Comparability

Process validation is a key part of the development and manufacture of all approved drug products, but its completion can be a daunting task. At a two-day CASSS CMC Strategy Forum held in July 2016 in Gaithersburg, MD, speakers and attendees addressed the many technical, practical, and regulatory facets of drug product process validation and comparability. In part 1 of this report, we summarize the key discussion points of the first day, which focused on analytics and comparability. Session One:…

Customized Yeast HCP Quantification with Biolayer Interferometry Using a Horseradish Peroxidase Substrate

Biopharmaceuticals are the largest group of drugs under development (1), and the demand for new and safe drug products is high. The most common bacterial and mammalian cell lines for production are Escherichia coli, Chinese hamster ovary (CHO) cells, and yeast. During a production bioprocess, a cell line expresses not only the molecule of interest, but also host-cell proteins (HCPs). They are considered to be impurities in a final drug product because they can affect the efficacy and safety of…

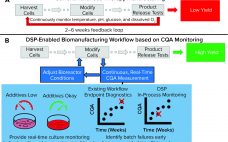

Improving Cell Manufacturing Outcomes Using In-Line Biomarker Monitoring

Cell-based advanced therapies are changing modern medicine dramatically. Immunotherapies such as chimeric antigen receptor (CAR) T-cell therapies are treating different forms of cancer. Gene therapies are reversing the course of inherited diseases, and tissue-engineered medical products are restoring, maintaining, and replacing damaged organs (1–4). The development of new advanced therapies is booming. As of January 2020, the US Food and Drug Administration (FDA) has reported more than 900 investigational new drug (IND) applications for cell and gene therapy products. However,…

Ask the Expert: New and Improved Analytical Methods for Traditional and Unique Modalities

On 10 December 2020, BPI presented an “Ask the Expert” webinar with Jason Sterling, PhD (principal scientist and project director in analytical and formulation resources), and John Rockwell (group leader) of Catalent Pharma Solutions. Biophysical characterization is critical to understanding the makeup and behaviors of biologic therapies and vaccines both early in development and throughout scale-up for manufacturing. As biologics become more complex in structure and as scientists improve their understanding of the effects of structure on stability, efficacy, and…

Ask the Expert: Developing Strategic Analytical Programs for Therapeutic Peptides

Ashleigh Wake began her 15 October 2020 “Ask the Expert” presentation by pointing out that peptide products are manufactured in a “regulatory vacuum.” Peptide-product developers must be strategic in designing characterization and quality control (QC) programs. Wake reviewed available methods and explored key considerations for developing phase-appropriate analytical controls. Wake’s Presentation Because peptides overlap small- and large-molecule drugs in size, regulatory expectations differ by product size and clinical indication. Thus, analytical programs should be designed around critical quality attributes (CQAs)…

COVID-19 MAbs should be made with combination in mind says US FDA

Monoclonal antibody (mAb) manufacturers aiming for an EUA should prepare for their SARS-CoV-2 therapies to be combined with others, according to the US FDA. The US regulator issued the advice in guidance this week in which it also urged developers to collaborate and share data. The FDA said, “Strongly recommends that individual monoclonal antibody products be developed with the expectation that they will be combined with one or more monoclonal antibody products that bind to different epitopes to minimize the…