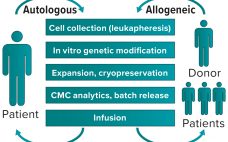

Initial progress in cell and gene therapy has seen 12 advanced therapeutic medicinal products (ATMPs) become available on the market in 2019 for a range of conditions, from monogenic diseases to cancer. Despite such progress, development of clinically and commercially successful cell therapies presents manufacturability challenges and questions about bypassing patients’ immune systems. The availability of rapid sequencing and next-generation bioinformatics has made it possible to understand the mechanisms of disease better and accelerate development of therapeutic responses. The same…

Personalized Medicine

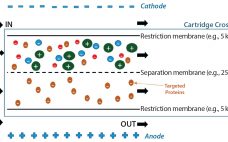

Tangential-Flow Electrophoresis: Investigation of Factors Involved in an Effective Separation of Human Serum Albumin from Human Plasma

Human plasma is a complex mixture of biomolecules such as serum albumin, immunoglobulins, coagulation factors, and others (1). These important protein biomolecules often are present at low levels or lacking in affected patients with certain life-threatening conditions. To extract those valuable proteins, a number of purification methods have been developed over time. Plasma fractionation can be traced back to the middle of the 20th century, when Edwin Cohn of Harvard University developed the first industrial process to purify proteins from…

eBook: Bioinks for Bioprinting — Three-Dimensional Printing in Research and Medicine

Three-dimensional (3D) printing is one method of digital biomanufacturing for both basic biological research and translational, clinical applications. The medical field has used it to create such constructions as 3D surgical models for preoperative planning, to assist surgeons in their procedure preparations, which improves postsurgical outcomes. Examples here include generation of cleft-palate models (1), orthopedic applications (2), and cardiovascular surgical planning (3). Other forms of 3D printing for biological applications — such as 3D bioprinting — go beyond such surgical…

3D Bioprinting Possibilities and Challenges

Three-dimensional (3D) bioprinting is the newest addition to the regenerative medicine family. Now within the industry dedicated to providing more personalized drug products, this new additive-manufacturing technology has the potential to truly focus on individual tissue repair and replacement. In a short period of time, 3D bioprinting has been applied in studies using bones, blood vessels, composite tissues, vascular grafts, tracheal splints, cartilaginous structures, heart tissue (e.g., two-valve heart), and vaginal organs (1). View the full article below – Login…

Outsourcing and Biomanufacturing Challenges for Emerging Therapies: A Roundtable Discussion at BIO 2016’s BPI Theater

The biopharmaceutical industry is increasingly interested in a range of emerging therapies. “We’re really starting to get beyond the monoclonal antibody,” said Patricia Seymour (senior consultant with BioProcess Technology Consultants) in her introduction to a lunchtime BPI Theater roundtable at the 2016 Biotechnology Industry Organization annual convention in San Francisco, CA, this past June. The discussion brought together three industry insiders for strategic outsourcing to talk about emerging biotherapies and their manufacturing challenges: Mark Angelino (senior vice president of pharmaceutical…

Cancer Immunotherapies: Fulfilling the Promise of Protein and Cell Therapies

With few exceptions, both small-molecule and biological cancer treatments have contributed only incrementally towards achieving long-term responses or outright cures. In this regard, emerging cell- and protein-based cancer immunotherapies represent game-changing strategies for treating even refractory cancer. With long-term responses now possible, medical science may be on the verge of delivering on the long-unfulfilled promise of making cancer a manageable disease. But impediments to commercializing cancer immunotherapies are substantial. Producing cell-based treatments entails substantial hands-on manipulation and perfecting the logistics…

Automation of CAR-T Cell Adoptive Immunotherapy Bioprocessing: Technology Opportunities to Debottleneck Manufacturing

Continued clinical efficacy demonstrations of cell-based immunotherapies (iTx) such as chimeric antigen receptor T cell (CAR-T) therapies has made the prospect increasingly likely of an immunotherapy product achieving conditional market authorization in the short term. For example, Novartis and the University of Pennsylvania’s lead candidate (CTL019) for treating a range of hematological malignancies received breakthrough status from the US Food and Drug Administration (FDA) in 2014, permitting access to an expedited drug development pathway for high unmet medical needs (1).…

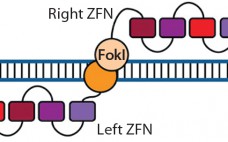

Therapeutic Gene Editing: Tools to Facilitate Basic Science or Stimuli for a Paradigm Shift in Biomanufacturing?

Historically, fundamental science and process engineering were separated by distinct vernaculars and a decade or more in the translation pathway of candidate therapeutics from laboratory to bedside (1). This crude metric holds true for the origins of the modern pharmaceutical industry, namely fine chemicals that supported the high-margin small molecules that constitute the majority of the pharmacopoeia even today. But as illustrated by deeply interwoven careers, companies, and technologies — including those related to monoclonal antibodies (MAbs) — that classic…

Collaboration Will Drive Regenerative Medicine: Toronto Development Center Will Help to Advance the Field

With support from the federal government of Canada, GE Healthcare and the Centre for Commercialization of Regenerative Medicine (CCRM) are pushing into new frontiers to advance the progress of cell therapy and regenerative medicine. When I first met Michael May, president and chief executive officer (CEO) of CCRM, both our organizations had been exploring opportunities in parallel to drive the cell therapy industry forward. CCRM’s mission is to create and sustain a global nexus for company creation, technology and cell…

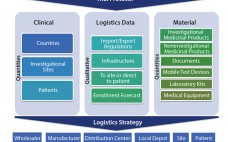

Clinical Supply Chain: A Four-Dimensional Mission

A clinical supply chain fulfills perfectly all four characteristics of what Packowski describes as a “VUCA” (volatility, uncertainty, complexity, and ambiguity) world (1). In commercial markets, supply chains depend predominantly on consumer orders. For global drug development programs, both investigators and patients can be considered end consumers. The international journey of a specific investigational medicinal product (IMP) includes all of the following: global sourcing of comparators, manufacturing, storage, distribution, site/patient (consumer) management, and return and destruction of the IMP. Application…