In bioreactors, microorganisms or cell cultures produce complex therapeutic proteins and other biopharmaceuticals. The industrial production of those active pharmaceutical ingredients usually involves a seed train: the cells are run through many cultivation systems, which become larger with each passage (Upstream Process). An adequate number of cells for the inoculation of large-scale production bioreactors of 10,000 liters or more is generated. A prominent example from the growing mammalian cell culture processing sector is the upstream production process of monoclonal antibodies.…

BPI White Papers

Rapid Process Development: How a Synthetic Depth Filter Offers a Platform Approach for Efficient Virus Filtration Operations

Virus filtration is a critical unit operation in recombinant protein purification processes. Process development of virus filtration operations typically strives to maximize filter capacity and improve process robustness. Adsorptive prefilters are often used to remove higher order protein aggregates and improve filter capacity. While adsorptive membrane prefilters offer easy scale up and implementation, their narrow operating window may result in extensive process development screening studies. By contrast, synthetic depth filters offer a wide operating window and the potential for a…

Not All cGMP Transfection Reagents Are Made Equal: Pharmaceutical Versus Medical Device cGMP Manufacturing

cGMP grade transfection reagents should be produced and formulated following strict guidelines. Some suppliers manufacture transfection reagents according to medical devices cGMP standards which makes the reagents suitable for viral vector manufacturing in the United States but not suitable for direct administration into humans. Those are often labelled as “for research use only and further manufacturing. Not for use in humans or animals”. Others comply to pharmaceuticals cGMP guidelines, making the transfection reagent suitable for viral vector manufacturing as well…

Lab Scale Depth Filtration with FILTROSPIN™ 20

FILTROSPIN™ 20 by FILTROX enables you to quickly and efficiently test different depth filters or quickly purify a small amount of liquid. The filters are inserted into standard 50 mL centrifuge tubes (Labcon® SuperClear® 50 mL tubes). The liquid is then filtered using a centrifuge or vacuum. In order to evaluate the most suitable and optimized production process, small-scale trials are the key factor to start with. With the help of laboratory scale trials, errors and other issues can be…

Application of Dry Granulation to Facilitate Raw Material Handling

Pharmaceutical and biopharmaceutical manufacturing relies on the timely and seamless orchestration of many steps to meet aggressive timelines and ensure operational efficiency. A fundamental element of the processing workflow that can impact schedules is the use of multi-ton quantities of bulk raw materials such as buffers, salts and stabilizing chemicals. These raw materials are typically prepared in a just-in-time manner to meet dynamic production needs and enable rapid changeovers.

Optimizing Feed Strategies with Cellvento® ModiFeed Prime Comp: A Scalable Process

Development of upstream processes, that maximize productivity without increasing complexity, relies on the right combination of medium and feed and the ability to maintain tight control of culture conditions. In fed-batch mode, cells are initially grown in a relatively lean production medium followed by regular feed supplementation to achieve the desired product yield. This App Note presents an optimized feeding strategy and demonstrates how a new, easy-to-hydrate, single-part, pH neutral feed can support optimal cell growth and high productivity of…

Intensifying Upstream Processing and the Implications for Media Management

Process intensification offers many benefits but implementing PI can introduce an unexpected challenge of managing larger media volumes. This whitepaper covers the implications of media management when developing PI strategies. Key Learning Objectives: Gain the tools and knowledge needed to confidently assess intensification options with a focus on media management for new or existing facilities. Follow the media journey from prep to use, exploring potential logistical pitfalls in the management of increased media volumes associated with process intensification. See how…

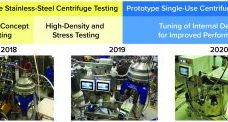

Intensified Mammalian Cell Culture: Harvest with a Single-Use Hermetic Centrifuge System

The production of increasingly higher cell densities has stressed the already limited solids-handling capabilities for traditional intermittent ejection centrifuge systems. By contrast, a single-use disc-stack centrifuge based on the solids-flow principle offers distinct advantages for cell culture harvesting. Such benefits include solids handling of high-density cell culture processes and elimination of the separation disruption and aerosol generation associated with the intermittent solids ejection. A single-use system also provides well-established benefits of disposable components — such as removal of steam- and…

Ligand Binding Assays: Return on Investment Analysis using Octet®

Octet® systems enable analytical assessment of biologics in various stages of the development workflow beginning with discovery and early selection to validation, manufacturing and quality control. The instrument’s configuration and sample plate format coupled with real-time analysis allows for rapid assay method development. In the last couple of years, Octet® systems have been used by multiple organizations to generate supporting data submitted to various regulatory bodies for the approval of different biologics drug candidates. In addition, Bio-Layer Interferometry (BLI) technology,…

Automation Solutions for the Efficient Integration of Single-Use Equipment

Single-use process technologies have been increasingly incorporated into the manufacturing of biopharmaceutical products over the past two decades. While the reasons for implementing SU systems for biomanufacturing are compelling, there are still some challenges and concerns related to their use. Process automation is often considered one of the weak points of single-use technology. Automation islands are frequent phenomena with SU systems, and integrating the equipment with larger automation systems is challenging. A number of suppliers – like Cytiva, Merck-Millipore, Sartorius,…