For all stages throughout the development, manufacturing and release of your biological product, Eurofins BioPharma Product Testing offers comprehensive, fully CGMP-compliant Viral Clearance Services. We have two dedicated clearance suites for extensive capacity and timely execution and reporting of your study results. And all of our assays are fully validated to meet ICH Q2 requirements. Why Choose Eurofins BioPharma Product Testing? We bring together leading experts in the industry with extensive scientific and regulatory experience. By supporting you from study…

Outsourcing

Minimize Risks and Enhance Speed and Flexibility with Sterile Fill/Finish Support for Clinical Supplies

Industry changes, such as shorter timelines and increased product complexity, can often introduce additional risks to the sterile fill/finish process, resulting in production delays, additional costs, and safety concerns. Additionally, the advent of personalized medicines brings challenges to manufacturing and supply chain structure, emphasizing the need for speed and flexibility. Join Eurofins BioPharma Product Testing and Vanrx (now part of Cytiva), for an in-depth discussion covering ways to eliminate human error and other associated risks when producing small batches of…

Establishing Commercial Manufacturing Services for Antibody-Drug Conjugates

The pipeline for antibody–drug conjugates (ADCs) includes hundreds of candidates, with several expected to receive approval in the near future. As more commercial products reach the market, there is an acute need for CDMOs that understand how to execute late-stage studies to support a filing strategy. CDMOs with plans to support commercial-scale ADC manufacturing are setting up processes to handle challenging supply chains and investing in facilities and processes to ensure efficiency, quality and security. In this white paper, we…

Embedding Your Drug Strategy Within a Solid Foundation for Success

Demand for drugs and therapeutics is growing thanks to the globalization of pharmaceutical-based medicine. Manufacturing new drugs and getting them to market faster, more economically and safely demands development strategies and business models that support successful outcomes for both investors and patients. Outsourcing has become an increasingly attractive business model for pharma as companies seek partners who can deliver comprehensive end-to-end drug substance and drug product development. It has prompted contract manufacturing organizations (CMOs) to consolidate and expand to create…

Scale-Out Biomanufacturing – A Paradigm Change to Scale-Up

In biomanufacturing, a production scale change is required to either meet the market growth demand or when a product moves from clinical to commercial manufacturing. How that volume is increased depends on whether a scale up or scale out philosophy is used. The industry standard has been to scale up, which translates to increasing the size of the bioreactors used in manufacturing runs. However, due to the recent availability and ease of single-use technologies, coupled with improvements in cell culture…

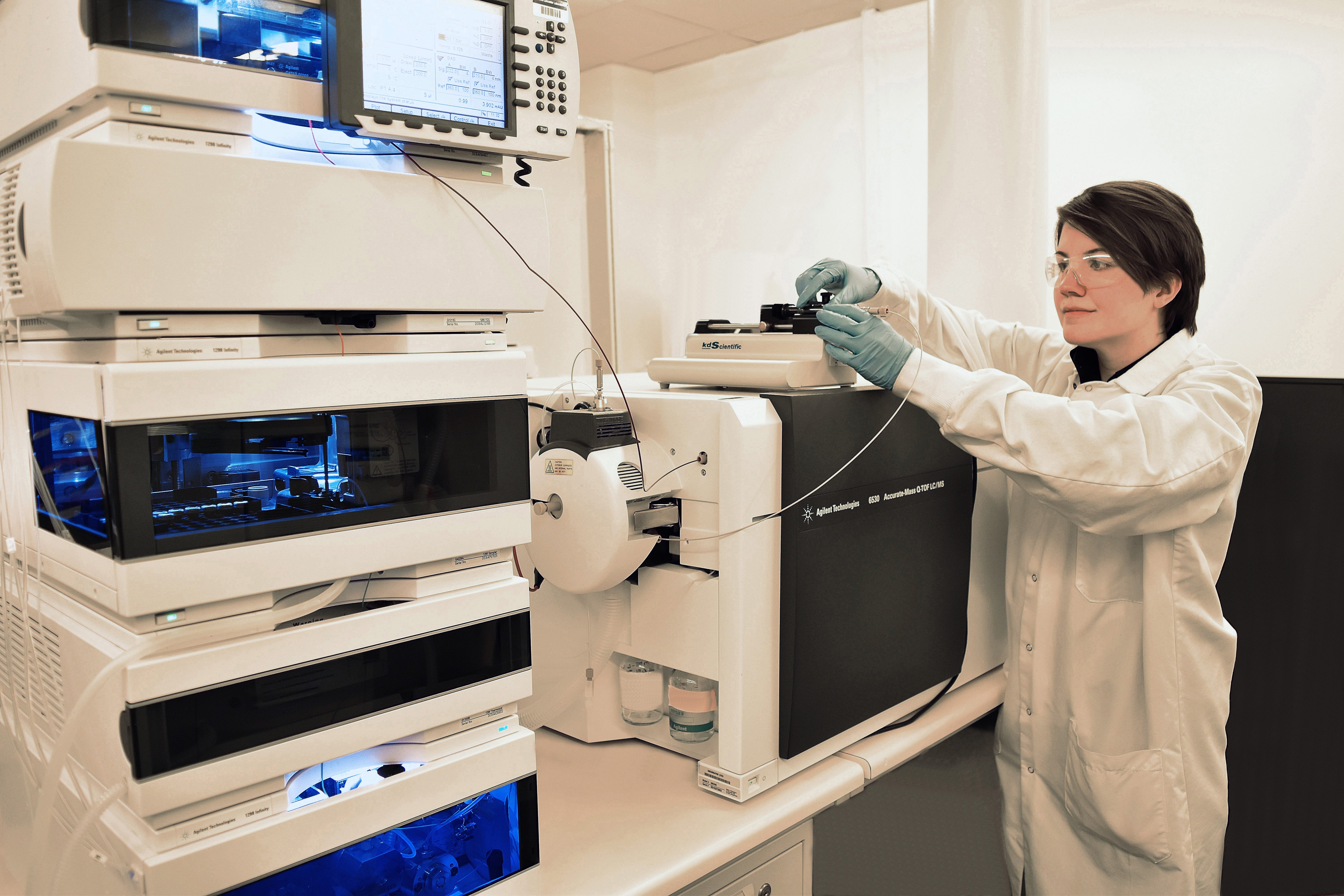

Extractable and Leachables Studies: Designed and Performed to Meet all Intended Needs

Since the FDA released their Container Closure Systems for Packaging Human Drugs and Biologics guidance in 1999, evaluation of final packaging components for extractables and leachables has become the expectation within the industry. Additionally, the increase in the use of single-use systems in manufacturing has drawn scrutiny as another potential source of extractables and leachables. Extractables are compounds that can be extracted from a product contact material under exaggerated conditions such as elevated temperatures, extended storage times, or exposure to…