In bioreactors, microorganisms or cell cultures produce complex therapeutic proteins and other biopharmaceuticals. The industrial production of those active pharmaceutical ingredients usually involves a seed train: the cells are run through many cultivation systems, which become larger with each passage (Upstream Process). An adequate number of cells for the inoculation of large-scale production bioreactors of 10,000 liters or more is generated. A prominent example from the growing mammalian cell culture processing sector is the upstream production process of monoclonal antibodies.…

Downstream

Rapid Process Development: How a Synthetic Depth Filter Offers a Platform Approach for Efficient Virus Filtration Operations

Virus filtration is a critical unit operation in recombinant protein purification processes. Process development of virus filtration operations typically strives to maximize filter capacity and improve process robustness. Adsorptive prefilters are often used to remove higher order protein aggregates and improve filter capacity. While adsorptive membrane prefilters offer easy scale up and implementation, their narrow operating window may result in extensive process development screening studies. By contrast, synthetic depth filters offer a wide operating window and the potential for a…

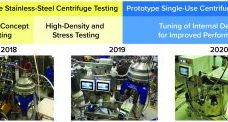

Intensified Mammalian Cell Culture: Harvest with a Single-Use Hermetic Centrifuge System

The production of increasingly higher cell densities has stressed the already limited solids-handling capabilities for traditional intermittent ejection centrifuge systems. By contrast, a single-use disc-stack centrifuge based on the solids-flow principle offers distinct advantages for cell culture harvesting. Such benefits include solids handling of high-density cell culture processes and elimination of the separation disruption and aerosol generation associated with the intermittent solids ejection. A single-use system also provides well-established benefits of disposable components ‚ÄĒ such as removal of steam- and…

Comparison of Gator BLI and Progen ELISA for Quantitation of AAV Serotypes

The determination of total capsid titer is one of the critical quality attributes for AAVs used in gene therapy. This application note presents quantitation of AAV serotype 2, 5, 8 and 9 using GatorPrime™ system and Gator™ AAVX probes, and compares the performance with Progen Xpress ELISA assay for the same serotypes. The Progen ELISA kit is commonly used for AAV quantitation and while it performs well, it has several drawbacks for routine operation, viz, need to dilute the samples…

Security of Supply Risk Mitigation in HCP Monitoring

The most common method scientists use to monitor host cell protein (HCP) levels in biologics is the enzyme-linked immunosorbent assay (ELISA). For the reagent, security of supply is a regulatory requirement ‚Ā†‚ÄĒ it‚Äôs a factor that‚Äôs critical to consistently monitoring HCP during biologic production. In this webinar, we discuss why security of supply is important, the consequences of not having it, and how to mitigate this risk. Topics covered Why security of supply is critical to your HCP plans Consequences…

Protecting Protein Stability with a Novel Grade of Sucrose

Ensuring the chemical and physical stability of the therapeutic protein is critical to the safety and efficacy of biopharmaceuticals and presents one of the major challenges in formulation. A number of excipients, including sugars, can be used to solve this problem. Sugars are stabilizers that maintain conformational stability by preferential exclusion and function as cryo- and lyoprotectors in lyophilized formulations. Given these properties, it is not surprising that sucrose is one of the most widely used stabilizers in marketed drug…

A Frost & Sullivan Virtual Think Tank: 3M™ Polisher ST Beta Testing Series

One step can change everything: Replace your flow-through AEX column with a novel single-use polishing solution 3M™ Polisher ST single use polishing solution – from lab to manufacturing scale Frost & Sullivan recently invited a panel of bioprocessing industry leaders and key opinion leaders to participate in a Virtual Think Tank (VTT) Early Access series ‚Äď a new and unique thought leadership forum. Each VTT panel, comprised of professionals from top pharmaceutical companies, contract development and manufacturing organizations (CDMOs) and…

Five Ways the Amersham ImageQuant™ 800 GxP Helps You Remain Compliant

In highly regulated environments, such as the pharmaceutical industry, remaining GxP compliant while efficiently delivering your products to a competitive market is a challenging task, particularly when Western blot imaging is involved. While this can often be a tricky and time-consuming task, our Amersham ImageQuant™ 800 GxP imaging system and software streamlines the process. It provides simple solutions that support data traceability, accountability, and integrity. Confident decision making and GxP compliance go hand in hand with high-quality imaging. In this…

3M™ Polisher ST ‚ÄĒ The Next Frontier in Downstream Processing, a Frost & Sullivan White Paper

Advancements in next-generation therapies‚ÄĒPaving the way for novel bioprocessing solutions. Learn about 3M Polisher ST technology which utilizes a guanidinium-functionalized polyamide membrane protected by a Q functionalized non-woven material. This Frost & Sullivan whitepaper explains how the technology demonstrates the viability of replacing the depth filtration and anion exchange chromatography (AEX) steps to achieve a simplified and cost-effective process. The platform is designed to reduce process and product related impurities and offer robust performance across a wide range of process…

MAb Quantitation: Protein A HPLC vs. Protein A Bio-Layer Interferometry

Rapid, accurate and cost-effective quantitation of monoclonal antibodies (MAbs) is essential for bioprocessing. High Pressure Liquid Chromatography (HPLC) and the Octet¬ģ are some of the commonly used techniques for MAbs titer determination. To ensure MAbs purification column efficiency, the dynamic binding capacity (DBC) of Protein A for Mab can be determined by loading feedstock onto the column until binding sites for the MAb become saturated and MAb begins to break through. An assessment of the relative merits of Protein A…