In biopharmaceutical manufacturing, cell culture media supply critical nutrients and maintain pH and osmolality to optimize protein product yield. Because media composition and condition have a strong effect on final biologic product quality and production, biopharmaceutical companies monitor media for lot-to-lot variability. Stability testing for degradation due to light exposure, temperature changes, or shelf-life/time is possible with rapid spectroscopic methods. In an 8 October 2019 “Ask the Expert” webinar, O. Dean Stuart (product manager at Thermo Fisher Scientific) explained how…

Analytical

Upstream: Make the Right Decisions for Your mAb

Bioprocess decisions made during upstream operations can be difficult to reverse at later, more costly stages of biologic manufacture. They even can require significant backtracking, wasting precious time, labor, and material. Read this Special Report to learn ways to optimize monoclonal antibody bioprocessing upstream. Specifically, you will learn about different tools that small and emerging biotechnology groups can use to ensure robust cell-line selection novel media formulations designed for intensified upstream processing in perfusion modes mixing and delivery solutions that…

Trends in Data Analytics As Organizations Undergo a Digital Transformation

The biopharmaceutical industry is in the midst of an exciting transformation as biologics experience massive growth — even outpacing the small-molecule segment (1). Biologics are predicted to comprise over a quarter of the pharmaceutical market in 2020 (2). At the same time, a plethora of new biologically derived therapy concepts — e.g., cell and gene therapies — are in development. Some biologics classes have become mainstream — e.g., monoclonal antibodies — with biosimilars entering the market and contract manufacturing organizations…

The Proof Is in the Data: Extractables and Leachables

Extractables and leachables (E&Ls) must be addressed in material and process validation programs. Extractables are compounds that can be extracted from a material in the presence of solvents with varying polarity under extreme conditions. Materials manufacturers should make extractables guides available to end users. Leachables are compounds that migrate from a material in the presence of an actual formulation under normal process operating conditions. Extractables information can be helpful as a basis for evaluation of potential process-equipment–related leachables (PERLs)testing. However,…

Analytical Testing Strategies for CAR T-Cell Products

Assay lifecycle development for traditional biopharmaceuticals such as vaccines and monoclonal antibodies (MAbs) has a clearly defined pathway, from preclinical method selection, development, and optimization through the milestones in preclinical phase trials, and finally to postlicensure method evaluations, comparability, and improvements. The analytical development roadmap for nontraditional biologics such as chimeric antigen receptor (CAR) T-cell therapies and gene therapies are not as clearly defined and can present many challenges along the way. Understanding the “what, how, and when” of analytical…

Measure Twice, Treat Once: Navigating the Regulatory Landscape of Assay Development to Ensure High-Quality CGT Products

Cell and gene therapies (CGTs) are a novel and fast-growing class of transformative therapies designed to address gaps in traditional treatment strategies of some of the most severe diseases. By definition, gene therapy “seeks to modify or manipulate expression of a gene to alter the biological properties of living cells for therapeutic use” (1). That can be either an in vivo delivery of a gene or delivery of a gene to a patient’s cells that are manipulated outside of the…

eBook: Speed to IND — Balancing Risk and Reward

With so many biopharmaceuticals obtaining breakthrough or fast-track designations, companies that use accelerated strategies to be first in human studies can be left with significant quality and manufacturing challenges that must be solved later on. Despite regulatory encouragement to create solid design spaces and define parameters according to quality by design (QbD), those may go by the wayside given the pressures of speed. The reward is the investigational new drug (IND) application itself — but if companies lock in subpar…

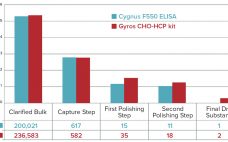

Host-Cell Protein Analysis to Support Downstream Process Development: A High-Throughput Platform with Automated Sample Preparation

In the past few years, increasing numbers of biotherapeutics have been approved for market (1). Among all the regulatory concerns for commercial biotherapeutics, host-cell proteins (HCPs) are a major class of process-related impurities that remains a critical quality attribute (CQA) for bioprocess development because of associated risks to product quality, safety, and efficacy. HCP identification, clearance, assay setup, and process control are critical points for health authorities, and many guidelines aim for better control of HCP content in final biologic…

Cell Viability in Bioprocesses: Making a Case for Reevaluation

Trypan blue dye exclusion first was proposed as a means of measuring mammalian cell damages over a century ago in 1917 (1). Despite extensive documentation of its limitations (2), it remains the “gold standard” method of measuring cell viability in common use today. But can this method truly measure viability? And how do we define cell viability, for that matter? Those fundamental questions are linked to whether we refer to cells as “alive” or “dead” in the context of bioprocessing…

Demonstrating Intactness of Biopharmaceutical Products: Intact Molecular-Weight Analysis and Terminal Sequencing of Proteins

Regulations require that biomanufacturers assess the intactness of protein and glycoprotein products as well as confirm the terminal sequences to look for existing variations. ICH Q6B guideline section 6.1.1 c states: Terminal amino acid analysis is performed to identify the nature and homogeneity of the amino- and carboxy-terminal amino acids. If the desired product is found to be heterogeneous with respect to the terminal amino acids, the relative amounts of the variant forms should be determined using an appropriate analytical…