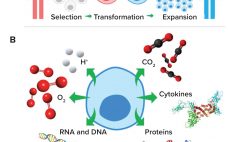

Cell and gene therapies are destined to transform the methods by which global healthcare challenges are approached and overcome (1). The US Food and Drug Administration is reviewing and approving an increasing number of cell and gene therapy products (2), and biopharmaceutical developers are dedicating immense resources to realizing the enormous potential of these therapeutics. Therefore, technologies that facilitate their effective and efficient manufacture will accelerate cell and gene therapies’ transition from medicines of the future to medicines of the…

Analytical

Soft Sensors for Bioprocess Monitoring

Achieving the high process efficiencies and optimization of Manufacturing 4.0 will require sophisticated software systems, mathematical modeling, and on-line process monitoring. Soft sensors are valuable tools that enable users to measure process parameters in real time. I spoke with Benjamin Bayer, data scientist at Novasign GmbH and doctoral candidate at the University of Natural Resources and Life Sciences in Vienna, Austria, about the potential of soft sensors for bioprocessing and important considerations for their use. Introduction How would you describe…

A Rapid, Low-Risk Approach Process Transfer of Biologics from Development to Manufacturing Scale

Successful scale-up of cell culture for manufacturing of biopharmaceuticals gives companies time to accelerate clinical development, product commercialization, and market access (1). Scaling a cell culture process in stirred-tank bioreactors ideally includes optimizing that process at laboratory scale and then transferring it through larger pilot-scale and finally to manufacturing-scale bioreactors (2). This is a complex, time-consuming business that can involve process transfer — sometimes to different geographical locations and through many sizes of bioreactors, each of which can operate according…

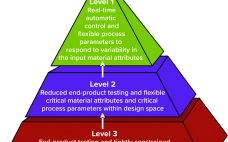

Developing Process Control Strategies for Continuous Bioprocesses

Process control enables biomanufacturers to ensure that operating parameters are within defined specifications. A control strategy should be established during early stages of process development while process and product performance are being defined using risk-based methods such as quality by design (QbD) and process analytical technologies (PATs). Confirming process control as an essential part of product development creates greater process knowledge and understanding and provides the first steps toward process optimization. By understanding how process performance relates to product quality,…

Are You Missing the Bigger Picture with Your AAV Analytics? Fast, Low-Volume Subvisible Particle Analysis for Characterizing Viral Vectors

Subvisible particle (SVP) analysis is a key indicator of stability and safety and is an essential parenteral drug quality metric. Yet assessment of SVPs is especially challenging in adenoassociated virus (AAV) vector formulations, in which limited precious sample is available. Traditional SVP methods consume large sample volumes, while dynamic light scattering (DLS), size-exclusion chromatography (SEC), and visual inspection can miss aggregates in the subvisible range entirely. This special report introduces backgrounded membrane imaging (BMI) technology as a solution for detection…

eBook: Development of Bioassays — A Report from the BEBPA’s First Virtual Meeting

Bioassay development is one of the most challenging aspects of biotherapeutic development. These tests are vital to providing an accurate picture of potency, stability, and biological activity. But bioassay development can be complex and expensive — and often test results can vary. Cell-based bioassays especially lack robustness. In March 2020, the Biopharmaceutical Emerging Best Practices Association (BEBPA) presented its annual bioassay conference in virtual format. Here, BPI’s senior technical editor reports on the conference’s discussions. Read on to learn more…

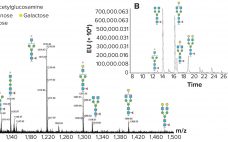

Building Orthogonality into Biosimilar Testing

Both the US Food and Drug Administration (FDA) and European Medicines Agency (EMA) have developed regulatory guidelines on biosimilars (1, 2). These comprehensive documents provide clear guidance on what the agencies expect from structural characterization studies. Using state-of- the-art instrumentation and techniques is expected, but the use of orthogonal techniques in structural comparability assessments is also required. The application of orthogonal analytical techniques will provide a firm structural foundation to claims of biosimilarity. Characterization methods verifying and supporting conclusions drawn…

A Future-Proof Solution for Bioprocess Applications: The New Eppendorf Flexible Bioreactor Control System Evolves with the Changing Needs of Modern Biotechnology

In the biopharmaceutical industry’s quality-by-design (QbD) era, optimizing tools for process monitoring and control has become a major focus of development and manufacturing. This increased attention brings challenges into upstream and production processes, cell-line development, process optimization, and scale-up. Suppliers of equipment and technologies also focus on helping their customers improve development timelines. With that increased attention to speed, they are offering tools such as the Eppendorf SciVario twin bioreactor control system to streamline development and maximize flexibility. BPI spoke…

Ask the Expert: Best Practices for Aseptic Sampling from Stainless-Steel Equipment

Turn-key single-use aseptic sampling devices (ASDs) have diminished bioprocess contamination risks significantly. But depending on testing, facility, and storage needs, some ASD container types are more effective than others are. Bobbi Allen (technology expert at Sartorius Stedim Biotech North America, SSB) focused her 8 January 2020 “Ask the Expert” presentation on “what, why, when, and where” operators must sample aseptically from stainless-steel tanks. Using data from in-house testing of aseptic sampling containers, Allen offered key considerations for sterility, process monitoring,…

Better Bioprinting Ahead: Breakthroughs and Remaining Challenges

Bioprinted organs soon could revolutionize clinical trials, transplantation, and regenerative medicine. But as Chris Lo reminds us in a new GlobalData report (1), several technical hurdles must be negotiated before biopharmaceutical companies can harness three-dimensional (3D) bioprinting for such purposes. BPI explores persistent printing problems and promising solutions below by analyzing Lo’s report alongside commentary from founding editorial advisory board member Bill Whitford (bioprocess strategic solutions leader at GE Healthcare Life Sciences), Lev Gerlovin (vice president in the life sciences…