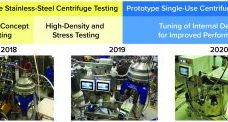

The production of increasingly higher cell densities has stressed the already limited solids-handling capabilities for traditional intermittent ejection centrifuge systems. By contrast, a single-use disc-stack centrifuge based on the solids-flow principle offers distinct advantages for cell culture harvesting. Such benefits include solids handling of high-density cell culture processes and elimination of the separation disruption and aerosol generation associated with the intermittent solids ejection. A single-use system also provides well-established benefits of disposable components — such as removal of steam- and…

Sponsored Content

Pharmaron’s cell and gene therapy webinar series

Pharmaron has taken their platform beyond small molecules and are pleased to now offer a full array of services for biologics and cell and gene therapies (CGTs). Our new CGT webinar series focusses on identifying key cell and gene therapy questions that arise during drug discovery and development. Register here for the series. Our second webinar, entitled Downstream AAV Production: A Targeted Approach to Optimization takes place on Thursday, March 24 at 9.00am ET. Join us as we highlight our…

WuXi Advanced Therapies Virology Operations: Cell & Gene Therapy Vector Regulatory Testing

This webcast features:Â Andreas Solomos, PhD, Director, Virology Operations, WuXi Advanced Therapies. Cell and gene therapy regulatory testing is a constantly evolving discipline as the field matures and data becomes more refined. Virology Operations at WuXi Advanced Therapies is able to provide testing for a variety of products ranging from small non-enveloped AAV vectors to large enveloped lentiviral vectors. Our testing is performed as quickly as testing parameters permit without sacrificing the quality and integrity of results. Our panel of testing…

Improving the Performance of Tried-and-True Chromatography Technology

Efficient and effective downstream processing of biopharmaceuticals reduces manufacturing costs and time. Chromatography is the primary purification method for traditional recombinant proteins, monoclonal antibodies (MAbs), plasmid DNA, and viral vectors. Although interest in membrane separation technologies is growing, traditional resin-based solutions continue to be preferred when high-resolution purification is required. Ion-exchange chromatography (IEC)(e.g., cation and anion-exchange chemistries) and hydrophobic-interaction chromatography (HIC) are established bioseparation technologies. Cation-exchange resins are used widely for MAb polishing and aggregate clearance steps. Anion-exchange (AEX) resins…

Mind the Gap: Managing Relationships Between Upstream and Downstream Intensification

Process intensification (PI) describes an integrated framework of strategies to maximize the output of a unit operation, a process, or an entire facility. By implementing PI strategies, biomanufacturers can accomplish their productivity goals by increasing production speeds and titers, reducing facility footprints, and cutting costs. Overall, such changes improve production efficiency and flexibility. Collectively, the biotherapeutic industry has made multiple advancements in intensifying upstream processing. PI strategies include using high-density cell banks, implementing seed-train intensification (n – 1 perfusion), and…

Ligand Binding Assays: Return on Investment Analysis using Octet®

Octet® systems enable analytical assessment of biologics in various stages of the development workflow beginning with discovery and early selection to validation, manufacturing and quality control. The instrument’s configuration and sample plate format coupled with real-time analysis allows for rapid assay method development. In the last couple of years, Octet® systems have been used by multiple organizations to generate supporting data submitted to various regulatory bodies for the approval of different biologics drug candidates. In addition, Bio-Layer Interferometry (BLI) technology,…

Automation Solutions for the Efficient Integration of Single-Use Equipment

Single-use process technologies have been increasingly incorporated into the manufacturing of biopharmaceutical products over the past two decades. While the reasons for implementing SU systems for biomanufacturing are compelling, there are still some challenges and concerns related to their use. Process automation is often considered one of the weak points of single-use technology. Automation islands are frequent phenomena with SU systems, and integrating the equipment with larger automation systems is challenging. A number of suppliers – like Cytiva, Merck-Millipore, Sartorius,…

Continuity of Methods: Characterizing Protein Therapeutic Stability From Developability Assessment to Release With Aura PTx

This webcast features: Bernardo Cordovez, CSO, Co-Founder, Halo Labs. Aura PTx is a complete protein therapeutic stability solution that enables characterization of subvisible particle aggregates from developability assessment through product release. Aura PTx is a high throughput analytical instrument that images, counts, sizes, and identifies subvisible particle aggregates, a critical quality attribute and the most important biologic stability parameter. Using volumes as low as 10 µL and with measurements of one minute per sample, Aura PTx enables rapid, highly contrast and…

Sustaining Project Management Business Continuity and Partnerships Throughout COVID

This webcast features: Patrick Haley, Sr. Director, Project Management & Business Operations, Avid Bioservices, Inc. The Avid project management office employed unique technology and communication techniques to maintain business continuity and material supply to our partners and the patients they serve throughout each COVID surge. This presentation will take a deep dive into the challenges and solutions encountered for each functional area in the biologics development and production process during the early COVID pandemic and later surges, while ultimately discussing…

Autologous CAR T-Cell Manufacturing Using a Semi-Automatic, Closed, Modular Workflow

There have been tremendous efforts to make CAR T-cells more effective, safe, and persistent when treating patients. On the manufacturing side, however, errors, lot-to-lot variation, and contamination can be associated with open processes and manual handling of CAR T-cells. Cell isolation, gene editing, expansion, and cryopreservation are complex steps in a typical autologous CAR T-cell manufacturing process. Integrating this complicated multistep workflow into a closed, modular, benchtop system can facilitate transitions from laboratory scale to clinical manufacturing and improve the…