The biopharmaceutical industry is adding mammalian cell culture capacity at rates that we haven’t seen in over a decade. Over the past five years (2012–2016), we estimate that industry-wide capacity has increased from 3.4 ML to 4.0 ML, an increase of 18% (1). We estimate that industry-wide capacity will increase over the coming five years (2016–2020) to 5.7 ML, an increase of >40%. Clearly, this growth is a response to the continued increase in demand for biopharmaceutical products and to…

Single Use

An Industry Proposal for Change Notification Practices for Single-Use Biomanufacturing Systems

Current practices for change notification in the biopharmaceutical industry are neither efficient nor conducive to accelerating the adoption of single-use systems (1, 2). Drug manufacturers (end users) often observe that supplier change data packages lack technical content or detail and that the time allowed for change implementation is too short. Occasionally, customers (end users or next tier in supply chain) learn of changes after the fact, possibly even by happenstance. Suppliers, however, can find the potential affect of a change…

BioPhorum Operations Group Technology Roadmapping, Part 3: Enabling Technologies and Capabilities

Although great strides have been made over the past 20 years to increase the productivity and robustness of manufacturing processes for biopharmaceuticals, the cost and complexity of their development and manufacturing remain high, especially in comparison with those of small-molecule pharmaceuticals. Process improvements are required to increase patient access while maintaining the viability of an R&D-driven biopharmaceutical industry. Facility productivity, cost of goods (CoG), and capital investment all have significant margins for improvement. Such goals can be achieved not only…

Extractables and Leachables: Standardizing Approaches to Manage the Risk

The implementation, maturation, and benefits of single-use technologies in biopharmaceutical development and manufacturing are well documented and understood. As analytical methods and testing services also rapidly improve, it is clear that management of risk associated with extractables and leachables also must evolve. Standardization is universally accepted as a goal; how to define, implement, and educate the industry is where debate resides. The container–closure segment has had more experience dealing with leachables and extractables than those implementing single-use process components do…

BioPhorum Operations Group Technology Roadmapping, Part 2: Efficiency, Modularity, and Flexibility As Hallmarks for Future Key Technologies

For a complex biopharmaceutical industry, setting out to forecast future technologies must involve considering how such technologies will be used. In the first article (1), I discussed why there was a need to develop a technology roadmap for the biopharmaceutical industry and the trends shaping its future: namely, the introduction of new product classes, the continued growth of the biopharmaceutical market, pressure to reduce costs, and uncertainty in approval and sales of new products. Herein I discuss the technology roadmap’s…

Single-Use Fill and Finish: An Interview with NNE Pharmaplan

I talked with NNE Pharmaplan’s Kim Vincent Andersen (single-use technology and biotechnology specialist) and Niels Guldager (global technology partner in biotech) to discuss their experiences with client facilities that incorporate significant elements of single-use technology. In particular, they highlighted a recent project for Novo Nordisk involving a large-scale greenfield filling and inspection facility in Hillerød, Denmark. Find more detailed information about the project online at https://goo.gl/yp4LQh. And you can watch a video about it here: https://youtu.be/czwwgdt3CxI. A Case Study You…

Elastomer Stoppers: Working Toward Adopting an Industry-Wide User Requirements Specification for Particulate Levels

Two years ago, the companies involved in the BioPhorum Operations Group (BPOG) fill–finish community agreed that the quality of elastomer stoppers for vials was causing problems for biopharmaceutical manufacturers. So they deemed it to be a priority for the group. The problem is particularly pronounced for vial stoppers used in legacy products, which may have been on the market for several years. Many such medicines remain valuable for large patient populations. The stoppers used on legacy medicines are manufactured using…

The First Single-Use Diaphragm Valve: Automated and Controllable Systems Increase Process Reliability

Single-use components and systems now are firmly established in the pharmaceutical and biotechnology industries. The trend toward simplified and flexible upstream and downstream plant design means that these components are becoming increasingly important — especially in biopharmaceutical production. In the past, the only available disposables were primarily tubes, fittings, and possibly filters. But the number of single-use systems has been increasing for a number of years now. It is hardly surprising that plant designers and operators now can rely on…

Design and Performance of Single-Use, Stirred-Tank Bioreactors

Single-use components and systems have been incorporated into many bioprocesses as an alternative to cleanable, reusable systems. A wide range of publications have detailed the reasons for this trend toward a single-use approach. Justification in many cases comes from process-specific benefits such as increased manufacturing flexibility — especially for contract manufacturing organizations (CMOs) — enhanced sterility assurance, elimination of cleaning, reduced capital investment, faster processing times with increased productivity, faster start-up, and other benefits (1). One critical factor in the…

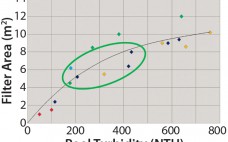

Development of a High-Performance, Integrated, and Disposable Clarification Solution for Continuous Bioprocessing

Current bioprocesses combine fed-batch cell culture with batch-wise downstream processing steps. To achieve integrated upstream and downstream continuous manufacturing, the industry has been in need of a continuous cell separation and clarification solution for bioprocess fluids from bioreactors. The Cadence Acoustic Separator from Pall Life Sciences provides this solution, with continuous first-stage clarification without the need for filter media in a scalable, single-use format with no negative impact on product attributes. The Cadence Acoustic Separator delivers cost and time savings…