Innovations in bioproduction of therapeutics over the past 20 years have led to impressive improvements in product yield, process controls, and manufacturing safety. Industry 4.0 concepts have been embraced across the bioprocess industry and are leading to better bioprocess control through process automation, “big data” and data analysis, process simulations, the industrial internet of things (IIoT), cybersecurity, the cloud, blockchain/serialization, and additive manufacturing. Such advances help to ensure that a process results in the same outcome every time. As Sean…

Single Use

Reacting to a Pandemic: Innovations in Vaccine Development

Traditionally, viruses for vaccines have been grown in embryonated hen eggs. But new challenges introduced by the COVID-19 pandemic have encouraged and catalyzed innovations in the field of vaccine development. The biopharmaceutical industry has recognized an advantage in mammalian cell-culture systems as promising alternatives to egg-based vaccine production. Cell lines can be cultured to large quantities in bioreactors, allowing for much shorter lead times, a more controlled production process, and a higher grade of reproducibility through standardization. In this article,…

The Green Imperative: Part Two — Engineering for Sustainability in Single-Use Technologies

In BPI’s June 2020 issue, the first installment of this series introduces the study and implementation of single-use (SU) technology to provide a more sustainable manufacturing environment (1). We presented evidence showing that the economic and social benefits of SU systems currently outweigh the residual environmental risks. Not only is SU technology often a better environmental choice than traditional biomanufacturing options, it also is sometimes the only choice for rapid process design and facility start-up. In situations such as the…

Silicone Tubing for Biopharmaceutical Applications: Particulates, Endotoxins, and Bioburden Characterization

Adoption of single-use systems (SUS) has increased steadily over the past few years driven by an increased focus on manufacturing biologics that require smaller scales than blockbuster drugs. Although SUS provide many benefits, some factors need to be considered when implementing them in biopharmaceutical production. With the regulatory landscape intensifying worldwide, drug manufacturers are expecting more data from suppliers to support the purity claims of supplied products, especially related to the purity of their product-contact surfaces. In this article, we…

Drug Formulations Are Changing:

New Sterile Filtration Challenges in the Changing Landscape of Drug Formulations

Read about the challenges of sterile filtration of high concentration mAbs, liposomes, and lentiviral vectors, and how to solve them in this Special Report. Development of new, complex drug formulations has given us therapeutics with properties that are markedly different from traditional drug types. High viscosity or low surface tension formulations or large viral vector molecules can mean that sterile filtration processes, which are optimized for traditional drug types, are not as efficient for the new, complex formulations. Premature filter…

The Green Imperative: Part One — Life-Cycle Assessment and Sustainability for Single-Use Technologies in the Biopharmaceutical Industry

Much has changed since large-scale single-use biomanufacturing equipment was introduced some 15 years ago. Since then, these materials have become accepted and established in production and downstream bioprocessing. Concerns about the environmental impact of single-use (SU) biomanufacturing equipment have become more prevalent as our environmental awareness has increased and related concerns have become more urgent (1). For example, many recommendations and even laws have emerged regarding plastic convenience packaging and products (2, 3). People have become more sophisticated in appreciating…

Applications of Disposable Technologies for Upstream Bioprocessing

Over the past 10 years, a number of developments in disposable (limited use) and single-use technologies (SUTs) have been made for different bioprocess operations. Until recent years, much of the industry’s process equipment was sterilized using thermal methods such as autoclaving. Most equipment was reusable and required cleaning and sterilization before use. Such processes required validation and expensive and time-consuming resources. Production facilities relied on hard-piped, inflexible equipment such as large stainless-steel bioreactors and holding tanks. However, advanced SUTs now…

Managing Risk in Single-Use Systems Design and Implementation: A Shared Responsibility

Managing risk in single-use systems design and implementation is a shared responsibility. The ultimate responsibility for drug processes and products will always remain with manufacturers. However, implementation of single-use systems can shift responsibilities to suppliers within key areas, including design and sterilization, which must be clearly controlled and validated. This Special Report discusses how suppliers and manufacturers when working together can mitigate the risk of applying single-use systems in biopharmaceutical production from design through validation to point-of-use testing and operator…

eBook: Continuous Bioprocessing — Promises and Challenges

Biotechnological productions are commonly executed as batch processes, especially during downstream processing. Higher titers in fermentations, reductions in operating scale, and the quest for improving product quality all have led to an intensified effort for developing continuous processing. It is forecasted that within the next 10 years, about 50% of all drugs under development will be biopharmaceuticals, making it worthwhile to develop more efficient processes. In this BPI eBook, Babu Halan (project engineer) and Wolfgang Minas (global lead of the…

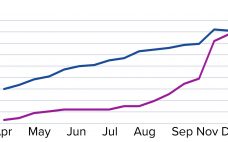

Trends in Data Analytics As Organizations Undergo a Digital Transformation

The biopharmaceutical industry is in the midst of an exciting transformation as biologics experience massive growth — even outpacing the small-molecule segment (1). Biologics are predicted to comprise over a quarter of the pharmaceutical market in 2020 (2). At the same time, a plethora of new biologically derived therapy concepts — e.g., cell and gene therapies — are in development. Some biologics classes have become mainstream — e.g., monoclonal antibodies — with biosimilars entering the market and contract manufacturing organizations…