Drug delivery is advancing into a digital future. Information technology is changing aspects of every operation in the biopharmaceutical industry. Meanwhile, machine learning and cloud computing are not only finding their way into drug development, manufacturing, and distribution, but also into drug-product delivery devices themselves. As a result, many biopharmaceutical companies are seeking medical device expertise through strategic alliances and contract services. New delivery devices can help big companies extend patent protection on established marketed products, for example, and provide…

Information Technology

eBook: Drug Delivery —

Tracking Therapeutic Antibody Development in a Pandemic

The COVID-19 pandemic has generated a significant and rapid response from scientists who aim to develop drugs and vaccines in the academic, government, and industrial sectors. Such interventions are essential to containing SARS-CoV-2, the coronavirus that causes the COVID-19 disease. To inform and educate the public about global efforts to develop targeted therapies such as monoclonal antibodies (MAbs), The Antibody Society (TAS) and the Chinese Antibody Society (CAS) have designed and implemented a freely available online database called the COVID-19…

New Data Analytics Tools Can Improve Bioprocess Workflows — If Applied Correctly

Biotherapeutics are a hot topic right now — and for good reason. But even before the COVID-19 pandemic, the biotherapeutics field, like every other manufacturing sector, was exploding with all the data that are being generated by recent innovations in equipment, systems, and processes. Advances in biomanufacturing analytics, analytical technology, and machine learning have tried to keep pace; however, such tools too often are misunderstood and applied suboptimally. Thus, many companies struggle with confusion and missed opportunities when they should…

Democratizing Access to Cancer-Related Proteomic Data

The US National Cancer Institute (NCI) has launched the Proteomic Data Commons (PDC), a next-generation proteomic data repository that will facilitate data access, sharing, and analysis to speed development of precision-medicine therapies for cancer. Housed within the NCI’s Cancer Research Data Commons (CRDC), PDC hosts several multiomic data sets that have corresponding genomics and imaging data elsewhere, simplifying their access to enable integrative research. Increase Access to Enable Discovery Mass spectrometry (MS)–based proteomic profiling for pancancer analyses could enhance our…

Finding Efficiencies to Accelerate Biopharmaceutical Development

An old engineering adage says that in any technical project, you can get speed and/or quality and/or cost-efficiency — but you never get to have all three. The idea is that emphasizing any one of those parameters necessarily deemphasizes one or both of the others. For most of the biopharmaceutical industry’s early years, companies operated on that assumption. Many organizations saw speed as the weakest link that could be more or less ignored; others had money to burn. The smartest…

Challenges and Benefits of Networking Process Control Manufacturing Systems: Integration to Business Systems in Industry 4.0

Networking of manufacturing process control systems can lead to benefits of efficiency, increased productivity, and better facility use, leading to lower cost of goods (CoG). Furthermore, integration of manufacturing systems with manufacturing execution systems (MESs) upward to an enterprise resource planning (ERP) business system improves overall organizational efficiency. An ERP system enables optimization of intrafacility manufacturing resources. For multiple manufacturing facilities, it facilitates optimization across a company’s manufacturing network. Enabling Technologies and Systems At the enterprise resource planning level (Figure…

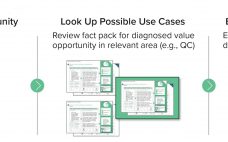

Designing the Right Strategy for Digital Transformation: How a Pragmatic Approach to Digital Transformation Can Help Biomanufacturers Adapt to a Challenging Future

Although the biopharmaceutical industry has enjoyed explosive growth over the past three decades, it still faces an assortment of challenges. Those include growing portfolio complexities, increased demand volatility, stringent regulatory requirements, increased pricing pressures, and growing technological complexities, all leading to severe pressure on profit margins. To overcome such pressures, biopharmaceutical operations need to become more reliable and agile, and they must realize efficiency gains in both manufacturing and supply chains. Digital transformation offers strong value opportunities, including a potential…

Soft Sensors for Bioprocess Monitoring

Achieving the high process efficiencies and optimization of Manufacturing 4.0 will require sophisticated software systems, mathematical modeling, and on-line process monitoring. Soft sensors are valuable tools that enable users to measure process parameters in real time. I spoke with Benjamin Bayer, data scientist at Novasign GmbH and doctoral candidate at the University of Natural Resources and Life Sciences in Vienna, Austria, about the potential of soft sensors for bioprocessing and important considerations for their use. Introduction How would you describe…

Bioprocessing 4.0 Accelerates Biological Research and Development Using Computer-Aided Biology

Computer-aided biology describes a growing ecosystem of tools that augment human capabilities in the laboratory. In this report we give two case study examples of how computer-aided biology has transformed industrial gene therapy bioprocessing. Read on to discover how Synthace’s Antha cloud-based software platform has enabled industrial collaborators Oxford Biomedica and the Cell and Gene Therapy Catapult to harness the power of Bioprocessing 4.0 by: incorporating new process analytical technologies (PAT), such as Raman Spectroscopy, into their unit operations automating…

Using Blockchain Technology to Ensure Data Integrity: Applying Hyperledger Fabric to Biomanufacturing

Digitalization of manufacturing operations is a major challenge that many industries face. With the advent of smart equipment, automation of unit operations and complete processes, and digitalization of batch documentation, more data are generated now than ever before. The information must remain manageable, and data integrity needs to be ensured. The challenge for biomanufacturers will be to ensure that their entire large output of data will be attributable, legible, contemporaneous, original, and accurate (ALCOA) as defined by the US Food…