It is well understood that freeze– thaw processes affect the product quality of biopharmaceuticals (1–3). It has been reported that there is no consistent method of controlled freezing and thawing rates for biological formulations (4). Traditionally, ultralow temperature storage chambers that were not designed for freezing have been used to provide an energy state for the environment surrounding the product with very little excess capacity to change the state of the product. This study details a consistent method for controlled-rate…

Formulation

Rapid Formulation Development for Monoclonal Antibodies

Monoclonal antibodies (MAbs) are at the focal point of biologics development. Many of the best-selling drugs are therapeutic MAbs or related proteins (1–2). The combined world-wide sales from MAbs will be nearly US$125 billion by 2020 (3). About 50 MAb products treating a range of diseases have been approved in the United States or Europe. With the large number of MAbs progressing through discovery, biomanufacturers need to accelerate process development and move projects rapidly into clinical manufacturing (4–5). Formulation development,…

Alkyl Mono- and Diglucosides: Highly Effective, Nonionic Surfactant Replacements for Polysorbates in Biotherapeutics — a Review

Many biotherapeutic proteins are naturally subject to aggregation. The clinical consequences of protein aggregation can be dramatic, not only affecting bioavailability and pharmacokinetics, but in extreme cases dramatically altering pharmacodynamics as well. Of equal or perhaps more importance is that aggregation is a principal source of unwanted immunogenicity in biotherapeutics. Aggregation-induced neutralizing antibodies and/or anaphylactic reactions are serious and growing US and European regulatory concerns. So they will have significant and growing influence on the future development and regulatory approval…

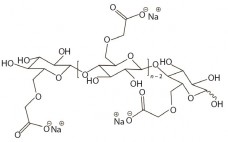

Factors Affecting Sterile Filtration of Sodium-Carboxymethylcellulose–Based Solutions

Carboxymethylcellulose sodium (CMC), is widely used as an excipient in oral, topical, and parenteral pharmaceutical formulations. It increases viscosity (1–3), serves as a suspension aid (4), and stabilizes emulsions (5). More recently, applications for CMC in formulations that facilitate improved delivery of cytotoxic drugs and biologics have been evaluated (6, 7). CMC is manufactured in a broad range of viscosities, with grades typically classified as low, medium, or high viscosity. CMC grades can be divided further based on their degree…

Outsourcing Stability Testing: Discussions with Contract Laboratories

Stability testing is required for all biopharmaceutical drug products to detect all changes in identity, purity, and potency as a result of a number of environmental and processing factors. Whether testing is conducted in-house or through contact laboratories, it involves the development and performance of comprehensive and specific stability protocols for all stages of a product’s life cycle (1). Testing product stability in-house requires signficant time and resources, and carries challenges associated with commercialization market, time, and capacity. Market: The…

Compatibility Assessment of a Model Monoclonal Antibody Formulation in Glass and Blow–Fill–Seal Plastic Vials

Blow–fill–seal (BFS) technology has been recognized by the industry as an advanced aseptic solution (1–3). Catalent Pharma Solutions has been commercially supplying sterile BFS products to the pharmaceutical industry for decades, primarily in the respiratory and topical ophthalmic markets. Such product formulations range from simple solutions to emulsions with drug substances from classical small molecules to large complex proteins such as biologics. The company also has optimized BFS processes and its Advasept plastic container system for the manufacture of sterile…

Biophysical Analysis: A Paradigm Shift in the Characterization of Protein-Based Biological Products

Generating a stable environment for a biopharmaceutical drug substance is a critical step for ensuring a long drug-product shelf life (1–6). This process begins early in development with preformulation screening. Some of the most critical parameters to maintaining potency and activity are protein conformation (tertiary or three-dimensional (3-D) structure), folding (secondary structure), and proper subunit association (quaternary structure). Collectively, those are known as higher-order structure (HOS) and can be highly influenced by the formulation environment of a protein drug product.…

Development of a High-Throughput Formulation Screening Platform for Monoclonal Antibodies

The goal of formulation development for therapeutic proteins is to find conditions under which a protein remains stable during storage, transport, and delivery to patients. Both chemical and physical stability must be considered. Chemical stability is related to the rates of chemical modification to a protein molecule such as deamidation of aspargine residues and oxidation of methionine residues (1, 2). Particularly important to control if they affect biological function, those modifications could also lead to changes in conformation or half-life…

Special Report on Product Stability Testing: Developing Methods for New Biologics and Emerging Markets

Stability testing is a vital part of product development and is conducted throughout a product’s life cycle (Figure 1). Stability is part of a biotherapeutic’s quality target product profile, and results help analysts understand how critical quality attributes (CQAs) of both drug substances and products are influenced under specific conditions of temperature, relative humidity (RH), light, storage, pH, and other factors. Manufacturers conduct stability tests to determine degradation pathways and establish shelf lives and storage conditions of their products, for…

The Importance of the Concentration-Temperature-Viscosity Relationship for the Development of Biologics

JIM DELILLO (WWW.FREEIMAGES.COM) Patient preference and a competitive landscape in the parenteral market have fueled the need for convenient delivery systems and a desire for less‑frequent dosing injections. Monoclonal antibodies (MAbs) often have high dose requirements, so they must be formulated at very high concentrations (1). At low concentrations, an antibody solution’s viscosity increases moderately as a function of protein concentration. But at high concentrations (>100 mg/ mL, depending on the molecule), viscosity increases exponentially (2, 3). Thus, a specification…