Biosimilars have become common on pharmacy shelves in Europe. The first biosimilar product — Sandoz’s Omnitrope version of Lilly’s Humatrope (somatropin) — was approved by the European Medicines Agency (EMA) in 2006. In the decade that followed, more than 20 biosimilars have gained regulatory approval in Europe. The first biosimilar monoclonal antibodies (MAbs) — comparators to Janssen’s Remicade (infliximab) — were approved in 2013. The pace of approvals in the United States has been much slower. The US Food and…

Business

Evolving Bioassay Strategies for Therapeutic Antibodies: Essential Information for Proving Biosimilarity

The modern age of biologics began 35 years ago with the approval of Lilly’s Humulin product — a biosynthetic form of human insulin derived from recombinant DNA and microbial cell culture (1). Today, about a quarter (27%) of the drugs approved yearly by the US Food and Drug Administration (FDA) and European Medicines Agency (EMA) are biopharmaceuticals: primarily monoclonal antibodies (MAbs), but also vaccines, blood products, and (recently), advanced therapies based on genes and cells. A decade ago, the average…

The Era of Digital Biomanufacturing

The digital revolution in manufacturing began with an explosion in monitoring, analytics, and new computing capabilities. Combined with such advances as artificial intelligence (AI), automation, and robotics, they are changing our concepts of manufacturing in general — from product development and factory operations to materials supply. This evolution also connects product and process designers and leaders in manufacturing engineering. Digital manufacturing (DM) isn’t a dream or a concept on some advanced developer’s design table; it’s occurring now and will change…

CMC Strategy Forum on Combination Products for Biopharmaceuticals: Emerging Trends in Development, GMPs, and Regulatory Expectations

On 26 January 2015, CASSS hosted a program in its ongoing series of semiannual Chemistry, Manufacturing, and Controls (CMC) Strategy Forums at the Mayflower Hotel in Washington, DC. Since this series’s inception in 2002, each installment has focused on one of a wide array of topics spanning the fields of biopharmaceutical product development, manufacturing, analysis, quality, and regulation. For this forum, the program committee chose to devote a full program to a topic that was previously the focus of an…

The Cell and Gene Therapy Industry: Looking at 2016 and Beyond

Politically 2016 was surprising and dramatic here in the United Kingdom and elsewhere. Although it was not surprising for cell and gene therapies per se, the growth that we have seen in this industry has been pretty dramatic around the world as well. The industry has seen investors of all types maintaining their interest in cell and gene therapy, with a number of new deals made: e.g., Bluebird bio and Medigene signed a strategic R&D collaboration and licensing agreement, and…

Critical Aspects of Technology Transfer to CMOs

Technology transfer in pharmaceutical manufacturing most often is mentioned as occurring between two organizations and involving discrete product lifecycle stages: e.g., a sponsor and a contract manufacturer and from development to manufacturing. According to the International Council on Harmonization of Technical Requirements for Pharmaceuticals for Human Use: “The goal of technology transfer activities is to transfer product and process knowledge between development and manufacturing, and within or between manufacturing sites to achieve product realization. This knowledge forms the basis for…

Growth Projections for the Regenerative Medicine Market

One of the fastest growing medical markets with great potential, regenerative medicine treats chronic diseases that were once untreatable. Therapy using live cells is increasingly used to replace damaged tissue, deliver gene therapies to target tissues and organs, and stimulate self-healing along with a number of other applications. View the full article below – Login Required Reference 1 Regenerative Medicines Market: Global Opportunity Analysis and Industry Forecast, 2015–2022. Allied Market Research: Pune,Maharashtra, India: August 2016; www.alliedmarketresearch.com/regenerative-medicines-market. 2 Chartrain NA, Williams…

BioPhorum Operations Group Technology Roadmapping, Part 2: Efficiency, Modularity, and Flexibility As Hallmarks for Future Key Technologies

For a complex biopharmaceutical industry, setting out to forecast future technologies must involve considering how such technologies will be used. In the first article (1), I discussed why there was a need to develop a technology roadmap for the biopharmaceutical industry and the trends shaping its future: namely, the introduction of new product classes, the continued growth of the biopharmaceutical market, pressure to reduce costs, and uncertainty in approval and sales of new products. Herein I discuss the technology roadmap’s…

Driving Therapeutic Innovations: Academic Institutions Can Help Lessen Development Risks

During the Biotech Week in Boston this past October, I had a chance to talk with David DiGiusto (Stanford University) about his work toward advancing bioprocessing and cell therapy development. I asked him to comment on points from his keynote presentation about how academic research groups can sustainably cycle assets into the biopharmaceutical pipeline. University research departments have long made innovative technologies available for commercial licensing. But in the excerpt below, he details ways in which such groups are further…

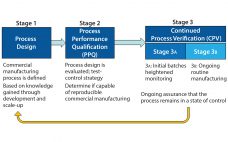

CMC Forum: Evolution of Biopharmaceutical Control Strategy Through Continued Process Verification

As defined in the ICH Q10 guideline, a control strategy is “a planned set of controls, derived from current product and process understanding, that assures process performance and product quality” (1). Every biopharmaceutical manufacturing process has an associated control strategy. FDA’s 2011 guidance for process validation (2) describes process validation activities in three stages (Figure 1). A primary goal of stage 1 is to establish a strategy for process control that ensures a commercial process consistently produces acceptable quality products.…