Design for manufacturing (DfM, also known as design for manufacturability) is a common approach in engineering industries when complex, multistep production processes are developed and installed to manufacture products. Adherence to DfM approaches has been prevalent for decades in the automotive, aerospace, and electronics industries, among others (1–3). Recently, a generalized manufacturability-assessment tool with strategies to weigh different aspects of manufacturing has been proposed with numerous similarities to that described herein specific to the field of bioprocess development (4). Although…

2020

Making Safe and Effective CAR T Cells: How Droplet Digital PCR Can Improve Their Quality Control

Chimeric antigen receptor (CAR) T cells first entered US clinics in 2017 (1), and this therapeutic modality holds tremendous potential as one of the most effective forms of personalized cancer care ever to reach patients. The revolutionary impact of CAR T-cell therapy comes from its ability to rewire our own immune defenses to kill cancer cells: It essentially modifies a patient’s naturally existing immune cells to boost their recognition and attack of cancer cells so that the person’s own immune system…

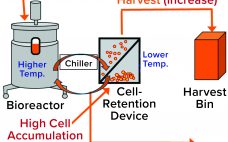

Product Quality Attribute Shifts in Perfusion Systems, Part 2: Elucidating Cellular Mechanisms

Part 1 of this two-part report describes an investigation into the potential cause(s) and ways to control a product quality attribute (PQA) of a protein expressed in perfusion cell culture (1). The presence of low–molecular-weight (LMW) species following size-exclusion high-performance liquid chromatography (SEC-HPLC) is a protein quality attribute that can indicate an increase in truncated forms of the expressed protein and/or other LMW moieties. The expressed protein in this study is a heavily glycosylated recombinant glycoprotein (rGP) comprising two subunits:…

Practical Considerations for Statistical Analyses in Continued Process Verification

Several statistical techniques can be used to assist in monitoring biopharmaceutical product quality attributes as part of continued process verification (CPV) activities. These include run charts, control charts, and capability analyses. Below, I provide an overview and recommendations on statistical strategies when developing a CPV program, considering the expected behavior of manufacturing results in the biopharmaceutical industry. Presence of Autocorrelated Data In a previous study, I highlighted the tendency for data to be positively autocorrelated (values are closely related to…

The Watershed Moment for ADCs Has Arrived — Now, CDMO Selection Is the Last Barrier

As far back as 10 years ago, antibody–drug conjugates (ADCs) were being talked about as the next big breakthrough in pharmaceuticals due to their highly targeted approach to therapies, especially in areas such as oncology. When Adcetris (brentuximab vedotin) became the second ADC approved by the US Food and Drug Administration (FDA) in 2011, it was predicted to be a watershed moment when the floodgates would open for more approvals and novel ADC approaches. Despite that possibility, the approval of…

Analytical Support for Biologics: A Conversation with Almac Sciences

Almac Sciences (a member of the Almac Group) recently expanded its suite of analytical solutions to include biologics testing. This follows a 2019 expansion of the company’s facility in Athlone, Ireland, where it provides a comprehensive range of flexible pharmaceutical testing services to support drug development programs adhering to industry regulations and good manufacturing practice (GMP) standards. “Biologics have gained huge traction in the past decade and are poised for stronger growth in the coming years with potential to significantly…

Ultrasonic Flow and Bubble Sensors: Optimize Process Quality in Single-Use Bioprocessing Applications

Process monitoring in laboratory and production environments enables continuous control and optimization of critical process parameters. Hence, the early detection of errors is an effective means of increasing process efficiency and reproducibility, improving quality and safety parameters, and reducing long-term costs. Highly precise and flexible noncontact clamp-on flow and bubble sensors are useful instruments to fulfill these goals. They can be applied effectively to buffer and media preparation, chromatography and filtration systems, bioreactors and fermentors, feed and transfer lines, and…

Evolving Business Models to Meet the Future of Healthcare

Yourway provides integrated supply-chain solutions for the global pharmaceutical and biotechnology industries. We exceed traditional offerings to provide customized support that includes warehousing and packaging, project management, planning and optimization guidance, comparator sourcing, ancillary-supply sourcing, forecasting, and returns/reconciliation management. Our single–specialized-provider approach offers clients a high level of convenience and efficiency that translates into quality, speed, and operational improvements. A Growing Global Footprint As we introduce new added-value solutions, expand our global footprint, and continue investing in infrastructure, technology, training,…

Case Study for a Facility-Fit Driven Process Development

Time to clinic and time to market are the key drivers for client success in the biopharmaceutical industry. Facility fit is becoming key to understanding process constraints and which aspects of the process have the largest impact on enabling facility fit. Process development with facility-fit constraints in mind will ensure a smooth technology transfer and shorten the timeline of current good manufacturing practice (CGMP) product delivery to clients. Fill out the form below to read this Special Report and learn…

Exploring Resin Modalities for Biotherapeutic Purification

New chromatography supports must demonstrate improved selectivity, and bead technologies must be optimized for high binding capacity and product recovery. Drug manufacturers also need access to expertise and continued support from chromatography suppliers that can assist with method development and design of experiments (DoE) assessments. Working together, these industry groups can accelerate method development, increase process yield, reduce buffer consumption, minimize the number of unit operations, and improve overall process economies. Learn more in this Special Report about how resin…