This webcast features: Steven Perry, PE, Senior Director of Manufacturing Sciences, Catalent Biologics Biologic drug substance development and biomanufacturing is a critical step in the long, complex pathway to approval. There are many considerations to be made around cell line and process development, analytical testing and late stage activities such as process characterization and validation. This presentation discusses: Critical drug substance resource needs of sponsor companies How expertise and collaboration amongst the key stakeholders enables successful development and scale up…

Friday, December 14, 2018 Daily Archives

Introduction: The Ins and Outs of Market Demand

From transport and holding of bulk drug substance to shipping, warehousing, tracking, and distribution of final packaged drug products, biopharmaceutical supply chain logistics can be described as an industry in itself. And that‚Äôs just one side of the story. Even though much of the work of establishing and maintaining supply chains might happen outside the manufacturing environment, all organizations that develop processes and final products depend on having the raw materials and available components and resources to do their work.…

Standardizing Human MSCs As Critical Raw Materials in Cell Therapy Products: Streamlining Clinical Translation

Advancements in cell therapy, biofabrication, and synthetic biology have driven the growth of the global regenerative medicine (RegenMed) industry in the past decade. The industry has developed innovative treatment options for patients with otherwise unmet medical needs (1). Human or animal cells or tissues are used as critical raw materials in cell therapy products that can replace, regenerate, or augment patients‚Äô diseased, dysfunctional, or injured cells, tissues, or organs. These cells or tissues can be unmanipulated, or their biological characteristics…

Spray Freeze-Drying Technology: Enabling Flexibility of Supply Chain and Drug-Product Presentation for Biologics

Biopharmaceutical drug substances (DSs) and drug products (DPs) commonly are stored frozen or refrigerated to maintain stability through long-term storage, handling, and transportation (1). Temperature excursions during storage and transport can affect product quality adversely by compromising the safety and efficacy of these molecules. Thus, cold-chain management throughout the shelf life of these products is a critical component in the supply chain strategy for them. The cost and complexity of cold-chain management is a well-known challenge faced by the biopharmaceutical…

November From the Editor

The word innovation carries with it connotations of both newness and change. Funny thing about that: Changing conditions require adaptation and originality in response to them ‚ÄĒ which often causes more change that will in turn require further innovation in response. In an industry based on science, this can (and should) be a neverending cycle either of playing catch-up ‚ÄĒ or of continually pushing the envelope. We hear a lot of talk about innovation in the biopharmaceutical industry these days.…

November BioProcess Insider

Launched in June 2018, the BioProcess Insider digital information portal delivers the latest financial and business news and expert insider views influencing the commercialization of biopharmaceuticals. Here are just a few recent stories edited for our space limitations in print. For more discussion and in-depth analysis, check out the website at www.bioprocessinsider.com. Every edition provides expert and insider perspectives on current financial movements and deal-making; the newest technology purchases and capacity investments; regulations affecting the bioprocessing sector; global market actions…

A Multistep Research Protocol to Develop and Implement Validated Guidelines for CMO RFI and RFP Processes: Biopharmaceutical Vendor Evaluation and Selection Minimum Standards (BioVesel)

Pursuant to the proposal for validated minimum standards for biopharmaceutical contract manufacturing organization (CMO) request-for-information (RFI) and request-for-proposal (RFP) processes (biopharmaceutical vendor evaluation and selection minimum standards, BioVesel) (1), we propose herein a multistep research protocol to develop and implement the BioVesel standards. This proposal is intended as a basis for discussion among mulitple stakeholders. Detailed research protocols for each proposed stage in the development and implementation of BioVesel will be drafted and published separately. The context of the proposed…

Building a Bridge Across the ‚ÄúValley of Death‚ÄĚ: Strategies to Help Support Technology Development

On Thursday 6 September 2018 at the annual BioProcess International Conference in Boston, the first ‚ÄúTechnology Round Robin Featuring Six Innovative Bioprocess Technologies‚ÄĚ was presented in an interactive session with attendees as active participants, asking questions and engaging in conversation with the six featured entrepreneurs. Detailed below, this session was a culmination of several steps in an overall strategy for some of the companies participating. To fully appreciate the launch of new technologies into the bioprocess arena, you first must…

Rolling with the ‚ÄėTides: Elucidating the Role of Peptides and Oligonucleotides in the Biopharmaceutical Industry

In earlier issues of BPI we published a few ‚ÄúElucidation‚ÄĚ closers that we called ‚ÄúDefining Moments.‚ÄĚ Since then, we have tried to distinguish key confusable terms from one another. Those presented (and sometimes ‚Äúelucidated‚ÄĚ) have been analytical and bioanalytical, spectroscopy and spectrometry, and biosimilars and biobetters. They are just a few of the many confusable terms in the biopharmaceutical industry. For example, when someone says ‚Äúdrug delivery,‚ÄĚ a formulator will think of a syringe or transdermal patch, but a logistics…

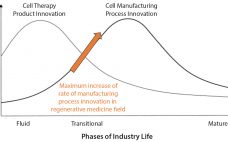

The Need for Adherent Cell Manufacturing: Production Platform and Media Strategies Drive Cell Production Economics

Most commercial biopharmaceuticals originated from academic research laboratories and start-up development laboratories. Despite such products having differences in modalities and targeted disease indications, and whether their target patient populations are relatively small or approaching blockbuster status, at a key point in development, biopharmaceutical production must scale up from laboratory to commercial production. That movement from research to development and then to manufacturing forces attention on economics and speed to market, and it drives innovative approaches to producing biopharmaceutical cell compositions…