This application note describes the cultivation of Chinese hamster ovary (CHO) suspension cells in the Finesse SmartGlass vessel bioreactor with a maximum working volume of 2.0 L. Using chemically defined minimal media, cell densities of up to 7.44 106 cells/mL were achieved. Recombinant secreted embryonic alkaline phosphatase (SEAP) expression was induced by medium exchange and temperature shift. Maximum SEAP activities of up to 63 U/mL were reached. A novel stirred glass bioreactor suitable for cell culture applications at benchtop scale…

Friday, August 15, 2014 Daily Archives

Reduce Cost, Increase Quality, and Shorten Cycle Time in Upstream Manufacturing with a Single-Use Heat Exchanger

Successful cell culture on a large scale requires close control of the culture environment in terms of temperature, pH, removal of waste products, and addition of fresh nutrients. To produce high yields of a desired protein, precise control over such parameters at every step in the process is required. Additionally, FDA regulations require various steps to be taken to control bioburden and maintain sterility. These controls and regulations in cell culture environments have led to an increasing move toward single-use…

Sky High Space Optimization for Biopharmaceutical Media

Ladies and gentlemen, welcome aboard ALLpaQ AIR. We have some preflight information about how this bioprocess container optimizes the air freight of media held under temperature-controlled conditions in an environmental chamber. Before lift-off, please place a single-use bag inside a bioprocess container, fill your media into the bag, and to maintain product temperatures load the bioprocess container inside an Envirotainer RAP e2 container. Now take count of how many passengers fit inside. One? Two? Three? Four? Owing to the dimensions…

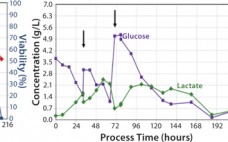

Improving Product Quality By Lowering Glucose Concentration

Cell culture is widely used for stable expression of monoclonal antibodies with posttranslational modifications. Despite having a stable cell line, a protein product is still in danger of improper modifications from chemical interactions with media. For example, the primary amino groups on a protein are susceptible to reactions with reducing sugar molecules. In the case of a reaction with glucose, this is called glycation. The relationship between glucose concentration and glycation is explored here. Methods: Chinese hamster ovary (CHO) cells…

Freeze-Pak™ STS Biocontainers and STS Shippers: Offering a New Single-Use Solution for Frozen Storage and Transport to -80 °C

Frozen storage is commonly achieved using single-use containers that enable manufacturing process flexibility and long-term product stability as well as minimize logistics challenges. Single-use containers also are available for storing and transporting frozen products although some require a significant investment, and others don’t offer necessary support and protection. Charter Medical recently developed a single-use frozen storage and transport shipping solution designed to complement single-use Freeze-Pakâ„¢ STS (FP-STS) biocontainers, which are engineered specifically for frozen storage applications. The bags and shippers…

We Know Bioprocessing

Through the combined strengths of the New Brunswickâ„¢ and DASGIP® product portfolios, Eppendorf now has the product portfolio and expertise to provide an outstanding range of premium equipment and single-use solutions to meet all needs. A New Scale of Bioprocessing From the parallel mini bioreactor system DASbox for early stage bioprocess development to the benchtop and parallel bioreactor systems for laboratory scale and the sterilize-in-place solutions for production, Eppendorf offers industry and research users its extensive bioprocess solutions from a…

The Global Leader in GMP Biopharma Product Testing

With the largest network of harmonized biopharmaceutical good manufacturing practice (GMP) product testing labs worldwide, Eurofins BioPharma Product Testing provides comprehensive laboratory services for the world’s largest pharmaceutical, biopharmaceutical, and medical device companies. We successfully enable companies to advance candidates from development through commercialization while ensuring regulatory compliance, cost effectiveness, and achievement of timelines. The Most Comprehensive Range of Large- and Small-Molecule Testing Services Available Worldwide Choose from a wide range of testing services that support all functional areas of…

Grow Your Cells with Insulin from Novo Nordisk

Danish-based FeF Chemicals is a preferred specialist supplier of premium quality ingredients for the biopharmaceutical and pharmaceutical industries across two unique product areas: insulin human AF for cell culture media and current good manufacturing practice (CGMP)-manufactured quaternary ammonium compounds (QUATS). And although high quality, innovation, flexibility, and security of supply are among its market-leading features, end-user patients are the motivators. FeF Chemicals supplies insulin human AF (for use in cell culture media) from Novo Nordisk, the largest insulin manufacturer worldwide.…

Global Biotech Expansion Demands Drive Local Manufacturing Needs

As major economies in the Asia–Pacific region continue to increase focus on healthcare modernization, new opportunities for both global and local biopharmaceutical companies are being created. Such opportunities are driving demand for local sourcing of raw materials to ensure security of supply. Modernization of Healthcare Drive Opportunities for Biopharmaceutical Firms Recent modernization of healthcare by governments has seen China pledge 124 billion to improve its healthcare system to provide insurance to 90% of its residents (1). South Korea introduced a…

Oxygen Measurement in Fermentation with VisiFerm DO: Optical Dissolved Oxygen Sensor for Microbial Fermentation

To achieve good growth of microorganisms and high yields in protein expression, the following factors in fermentation are important: medium, gas Fermentors for research and development have to meet very high standards for flexibility so that they can be easily adapted to the requirements of a wide range of microorganisms and process conditions. For that purpose, modular fermentation systems were developed, consisting of single modules such as drive, fermentation vessel, analytical instrumentation, stirrer, foam separator, ventilation, and so on. This…