This four-part educational series, sponsored by BioProcess International and BioPlan Associates, Inc., highlights key trends emerging in China biopharmaceuticals, using select content BioPlan Associates’ 2018 2nd edition report, Advances in Biopharmaceutical Technology in China, 2nd Ed. The quarterly series, each consisting of articles, an e-book, 40-min webcast, and live presentation at select BPI Events cover China’s Emergence in Global Biopharma Manufacturing: Trends in Chinese Biopharma Industry. The projects include an Overview, Developments in Biologics, Biosimilars, and Global Expansion. The series…

Sponsored Content

Bioprocessing Challenges and CMO Opportunities in China

This webcast features: Scott Wheelwright, PhD, Co-Founder and Principal, Complya Asia China’s biopharmaceutical manufacturing is significantly increasing, among domestic and international companies. Contract manufacturing services as well as those with potential to do so are rapidly changing as well. In Part 4 of our series, Dr. Scott Wheelwright, Co-Founder and Principal, Complya Asia, will provide an overview of factors affecting manufacturing, manufacturing trends by market, biopharmaceutical manufacturing in China among CMOs and developing companies. Watch the recorded webcast below.

Systems Compliance: A Risk-Based Approach to Software Management

This webcast features: Martin Laferriere, Director, IT Systems Compliance, Avid Bioservices Software systems risk management and evaluations should be part of your validation process. It is possible to reduce testing by documenting your risk, actual use, regulation impact, evaluating vendor(s), etc. The approach to managing the risk evolves through audits and prior experience and can tailor the management and approach to system quality within each organizations. In my experience and observations, an efficient system risk management is essential, and it…

BioContinuum™ Buffer Delivery Platform

Streamline your buffer preparation and management through an integrated combination of an automated buffer dilution system, high-quality buffer concentrates, single-use assemblies, and a tailored service package.

Single-Use Technologies: Accelerating Bioprocess Design with Key Insights from the Experts

Companies turn more and more to single-use technologies (SUTs) to mitigate production challenges — and with good reason. SUTs clearly decrease conventional costs while increasing process integrity. Yet as the writers in this compilation suggest, SUTs are now making possible new, exciting ways to configure, operate, and evaluate biomanufacturing. In this compilation, BioProcess International gathers key insights from biopharmaceutical industry experts at Sartorius Stedim Biotech to explore how SUTs can realize high-quality yet cost-effective end-to-end bioprocessing. The studies herein identify…

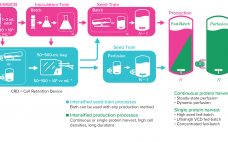

The Critical Role of Media in Intensified Upstream Processes

As the need for novel therapeutics increases, so does pressure on the biopharmaceutical industry to improve productivity, accelerate development, increase, and reduce costs — all while ensuring drug product quality. Upstream intensification strategies such as perfusion culture can address those challenges and achieve higher protein titers that can translate into higher throughput, improved flexibility, and compressed timelines. Successful implementation of perfusion culture or the transition to perfusion from fed-batch culture requires a different and strategic approach to media selection, not…

Addressing Regulatory Requirements for Filter Integrity Testing

Filter integrity is a fundamental element of sterility assurance during production of biopharmaceutical and vaccine products. Integrity test results are a key foundation for drug lot release, so any external element that could affect their reliability must be viewed as a critical issue. But when should a filter integrity test be performed? This article highlights the Sartocheck 5 Plus filter integrity tester as a means to address regulatory requirements. Please fill out the form below to read the full article…

Forward Thinking — Evolving the Cell and Gene Therapy Industry: Modern CAR T-Cell Process Addresses Future Demand

It is an exciting time to be involved in the cell and gene therapy industry. We have come to a tipping point where we have shown that the science works. Now we need to industrialize and standardize it, so we can get these life-saving therapies to more patients. As an industry, we can learn from all the experience in the biologics space. With monoclonal antibodies (MAbs), we have transitioned from a manual process to a more standardized and automated set-up.…

Ask the Expert: Clarification of Lentiviral Vectors Using Scalable Filtration

Researchers traditionally have produced lentivirus (LV) in adherent cultures by transient transfection using media containing animal serum. The method is inexpensive for process development (PD) and early clinical trials, but it requires increased operator manipulations and costs during scale-up. Development scientist Adam McLeod delivered an Ask the Expert webinar on 27 August 2019 to illustrate how GE Healthcare Life Sciences at the Centre for Advanced Therapeutic Cell Technologies (CATCT) in Toronto, Canada, approaches lentiviral vector (LVV) manufacturing. McLeod explained that…

Production of Transient Lentiviral Vectors in HEK 293T Cells: Cultivation on Fibra-Cel Disks in a Single-Use, Packed-Bed, Stirred-Tank Bioreactor

Although demand for lentiviral vectors (LVs) for cell and gene therapy is increasing, the standard two-dimensional culture systems used to produce LVs present significant disadvantages. Current bottlenecks in LV production are caused mainly by such disadvantages. Switching to use of bioreactors can eliminate those problems because bioreactors offer the benefits of process automation, tight regulation of production conditions, and reduced labor input. The study reported herein was carried out by the group of David Parsons at the University of Adelaide.…