This webcast features: Bernardo Cordovez, Chief Science Officer and Founder, Halo Labs In protein-based formulations, distinguishing aggregated active pharmaceutical ingredient (API) from other particle types is important for understanding the root cause of instability. Until now, existing methods have been either unreliable or too cumbersome to use in many workflows. Here we introduce the Aura™ 96-well low-volume aggregate and particle imaging system, which can rapidly size, count, and characterize particles and identify them as proteins, non-proteins, hydrophobic, or other types…

Sponsored Content

Translating Inhaled and Nasal Technologies for the Delivery of Biologics

This webcast features: Mark Parry, Technical Director, Intertek Inhaled and nasal delivery platforms have specific applications outside of their traditional uses for asthma/chronic obstructive pulmonary disease (COPD) and seasonal rhinitis/sinusitis: They can offer real advantages for the delivery of therapeutic biologics. During this short presentation, Intertek’s Technical Director, Mark Parry, will provide an overview of currently available technologies and successfully marketed products, with a look at the development challenges that might be encountered — and the solutions that are available…

Relative and Absolute Quantitation of Impurities and HCPs Using Mass Spectrometry

This webcast features: Steven Broome, Senior Mass Spectrometrist, BioPharmaSpec The processes involved in manufacturing a biopharmaceutical use biological and chemical systems to produce and purify the drug product. Therefore, the final active pharmaceutical ingredient (API) will often contain impurities related to these processes. It is a regulatory requirement to identify and monitor process-related impurities, and a qualitative and quantitative assessment of the components in the final drug product must be performed. Knowledge of the product-specific impurities, such as host-cell proteins…

Application of Targeted Locus Amplification for Enhanced Apollo X CHO Clone Screening

Speed to market is an important consideration for the development of lifesaving therapies, including recombinant monoclonal antibodies. However, increased speed must be balanced with quality to enable quick and efficient delivery of biopharmaceuticals to patients. Important determinants of quality include the genomic location and integrity of the transgene sequence within a recombinant cell line. Traditional methods of genetic characterization can provide incomplete information and results can be difficult to interpret. However, next-generation sequencing (NGS) approaches such as Targeted Locus Amplification…

Get to IND Faster: Accelerated and High-Performance Cell-Line Development

In April 2020, Samsung Biologics hosted a webinar with John Gill, the company’s director of cell-line development (CLD). He focused first on chemistry, manufacturing, and controls (CMC) activities needed for preparing an investigational new drug (IND) application. Then he introduced a fast timeline for managing CLD programs to accelerate client projects to success. CMC Activities Samsung Biologics is a fully integrated contract development and manufacturing organization (CDMO). Starting with a client’s gene of interest (GoI), Gill’s group tailors CLD to…

Writing the Future of Biologics to Discover and Optimize Antibodies

With our unique DNA writing technology, Twist Biopharma is accelerating the way our partners discover and optimize antibody therapeutics. We have decades of synthetic antibody library design and selection expertise and have the ability to write any DNA sequence to enable faster, better discovery and development. Using our precise, rational, expertise in library fabrication, we can create libraries in a fundamentally different way that allow us to address tough targets, e.g. GPCRs. Since we are a DNA product company, we…

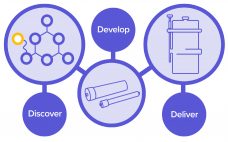

Discover, Develop, Deliver

Astrea Bioseparations is the only adsorbent supplier that can discover new affinity ligands designed to bind selectively to a molecule of interest or specific impurity, develop efficient purification adsorbents and downstream methods, and deliver industrial-scale adsorbents (up to 1,000-L batch sizes) as loose slurry or in good manufacturing practice (GMP)-ready columns. With over 30 years of experience in development of affinity products and design and manufacture of new custom adsorbents, Astrea Bioseparations is a world leader in its field. The…

Retrofitting Your Bioreactor to Enhance Stirring Processes: Replacing Old Agitators with State-of-the-Art Magnetic Mixing Technology

A key challenge for companies involved in drug development is to meet the highest standards of sterile design and reliability. In this context, magnetic mixers offers many advantages for aseptic stirring processes compared to mechanically sealed agitators. ZETA not only supplies magnetic agitators for new bioreactors, but also supports its customers through the entire retrofitting process, from feasibility studies at the beginning to full process qualification and validation at the end. “Combat the risk of batch contamination in bioreactors and…

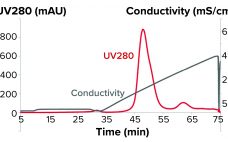

Reduce Downstream Processing Costs for MAbs By Switching to a Two-Step Platform

Downstream processing operations make up to 80% of the total costs for processing biotherapeutics. Given the current drive to reduce downstream costs, chromatographers and process engineers will need to streamline processes. Herein, we describe the benefits offered by using Tosoh’s two-step process for purifying monoclonal antibodies (MAbs) and compare that method with the standard industrial process. By combining high-performance protein A capture and a single polishing step on salt-tolerant anion-exchange resin, Tosoh’s approach can reduce downstream costs by 45% and…

Process Intensification of Viral-Based Vaccines: Where Are the Bottlenecks?

In the current coronavirus pandemic, the ability to scale up and produce viral-based vaccines (attenuated viral vaccines, inactivated viral vaccines, and viral vector vaccines) quickly and in large quantities has never before been more relevant. For viral-based vaccines that can be produced by adherent or suspension cell culture, process intensification — in which cell culture, for example, is optimized to produce higher viral titers using the same process equipment — offers a strategy to produce larger numbers of doses in…