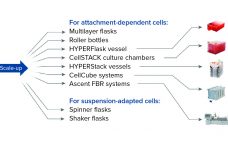

When considering strategies for expanding the number of cells being grown to support cell therapy development, companies often focus on decisions regarding scale-up and scale-out: increasing capacity either by using larger vessels to increase production volume or by implementing more units of the same vessel, respectively. Complete workflows often involve both. Figure 1 shows an example of scaling out from one to multiple cell culture flasks of the same dimension before transitioning to a larger format. Scale-out can be straightforward…

Manufacturing

Single-Use Technology for Formulation and Filling: A Case Study from Swissfillon AG and Pall Corporation

Swissfillon AG is a contract manufacturing organization (CMO) based in Switzerland. Fully compliant with current good manufacturing practice (CGMP) regulations, it provides state-of-the-art aseptic filling for pharmaceutical and biotechnology companies, from clinical-phase materials to commercial quantities. This CMO specializes in high-value, difficult-to-fill products. Swissfillon recognized that adoption of single-use systems (SUS) on a commercial scale required major improvements in consistency and reliability compared to manual operations at pilot and clinical-trial scale. The single-use formulation and filling process, which includes an…

Ask the Expert: Streamlining Mesenchymal Stem Cell Production — From Expansion Through Removal of Cryoprotectant

The number of cell therapy product candidates based on mesenchymal stem cells (MSCs) has grown steadily since their clinical debut in 1995. As of June 2020, clinical investigators were evaluating more than 1,100 such therapies. Scaling up MSC production remains challenging, however. On 31 May 2021, Hilary Sherman (senior scientist at Corning Life Sciences) presented an “Ask the Expert” webinar describing her company’s efforts to facilitate MSC workflows. Sherman’s Presentation Easing Expansion: MSCs have strong differentiation capability and can be…

The Next COVID Challenge: Building an Arsenal of Vaccines

For months, international partners have pressured the United States about intellectual property (IP) concerns and access to SARS-CoV-2 vaccines. As the country emerges from the worst of the pandemic, President Joe Biden now has an opportunity to shift his administration’s focus to realizing its longstanding promise of making the United States “the arsenal of vaccines for the world” (1). However, the country cannot accomplish that goal just by exporting mRNA vaccines and waiving IP protections. The current generation of vaccines…

eBook: Bispecific Antibodies — Their Development and Manufacture As Therapeutics

Generating antibodies with two or more specificities is one of the most innovative fields in therapeutic antibody development, with tremendous potential for use in creating new treatments for patients with unmet medical needs. In particular, bispecific antibody development is stimulating innovations in bioprocessing techniques from expression through upstream processing and candidate purification. Wherever possible, process-development scientists and engineers are borrowing techniques that were honed for mature monoclonal antibody (MAb) platforms, then applying those to bispecific antibody manufacturing. Nevertheless, the unique…

New Antibody Formats on the Block:

More Complex Modalities Demand Innovation in Manufacturing and Purification

Some of the latest, most promising therapeutic developments in the biologics industry use antibody fragments — either separate functional subunits of antibodies or recombinant molecules that are composed of immunoglobulin domains. The most popular fragments are antigen-binding fragments (Fabs), variable single-chain fragments (scFvs), diabodies, and nanobodies. Such molecules raise several advantages over their parent molecules for upstream production but pose several challenges for downstream purification. To facilitate antibody-fragment capture, Tosoh Bioscience has developed Toyopearl AF-rProtein L-650F resin. Its ligand uses…

High Virus-Titer–Producing Cell Lines for Bioproduction

Antiviral vaccines are essential for preventing epidemic disease. However, production of them often is limited by low-yielding manufacturing processes. Similarly, the development of gene therapies is constrained during the production of adenoassociated virus (AAV) delivery platforms for gene transfer. To address the need for efficient viral synthesis to quicken the pace of bioproduction, ATCC used CRISPR/Cas9 genome-editing technology to develop STAT1 and BAX knockout (STAT1 BAX KO) cell lines to produce high-titer viral stocks. Three cell lines optimized for virus…

28 Years of Experience Developing and Manufacturing Biopharmaceuticals

Avid Bioservices, Inc. is a full-service, dedicated contract development and manufacturing organization (CDMO) focused on biopharmaceutical drug substances derived from mammalian cell culture. Avid’s services include process development and current good manufacturing practice (CGMP) clinical and commercial drug-substance manufacturing, bulk packaging, release and stability testing, and regulatory submissions support. For early stage programs, the company provides process development activities such as upstream and downstream development and optimization, pilot-scale manufacturing, analytical methods development, and testing and characterization. Avid has 28 years…

Partnering with Innovators: From Raw Materials to Commercial-Ready Processes

Advancements in life sciences technologies and the increasing demands for improved, effective, and innovative products to prevent, treat, and in some cases, cure diseases have focused the attention of drug developers on new modalities such as mRNA-, DNA-, viral vector-, and cell-based therapies and vaccines. Novel biopharmaceutical products bring a level of complexity to developing and bringing them through design, clinical studies, and to the market. Like traditional drug products, complex therapies require robust, scalable manufacturing processes, a reliable quality-driven…

Corning X-WASH System: DMSO Reduction of Cryopreserved Human Mesenchymal Stem Cells

Cryopreservation is a necessary part of workflows for both autologous and allogeneic therapies. The ability to cryopreserve cells for cell therapy increases the range of administration, shelf life, and time for safety testing. Cryoprotectants such as dimethyl sulphoxide (DMSO) often are added to freezing media to increase post-thaw cell survival. However, DMSO itself can be cytotoxic, so reducing its final concentration can be necessary. Below, I demonstrate how the Corning X-WASH system can reduce the amount of DMSO used in…