Global manufacturing of biopharmaceuticals for human use helps save the lives of millions of people and is a large commitment to public health. The industry operates in an environment with financial uncertainties and complex international supply chains, so the question of risk mitigation is paramount. There is an expectation that comprehensive risk mitigation programs should be in place to minimize the risk of supply chain interruptions that would negatively affect the manufacture of these vital therapeutics. Here we share how…

Risk Management

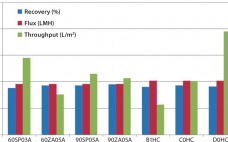

Strategies to Mitigate Technology Transfer and Clinical Manufacturing Risks: Downstream Purification Case Studies

Since the early 1980s, biotechnology products have been a fast-growing sector. They now occupy a significant portion of biologic drugs approved by regulatory authorities around the world every year. Among the approved biologic drug products, as well as those still in clinical testing, many are manufactured by contract manufacturing organizations (CMOs). Sponsor companies often transfer their developed process and process knowledge to CMOs for manufacturing of materials for toxicology and clinical studies. Drug Product Development Figure 1 illustrates the usual…

Risk Management in Financing of Capital Expansions: How One CMO Grows with Its Customers

BioVectra Inc. is an eastern Canadian contract manufacturing organization (CMO) with expertise in both synthetic chemistry and biomanufacturing techniques. In recent years, it has obtained specialized knowledge in production of highly potent small molecules from fermentation and functionalized methoxypoly(ethylene glycol) products (mPEGs). The focus of BioVectra’s contract manufacturing business is the transfer and scale-up of processes for manufacturing its clients’ products under current good manufacturing practices (CGMPs) as appropriate for the clinical stage of each product. In the current environment,…

Cell Therapy Manufacturing

Fueled by a recent resurgence in public financing and compelling clinical data for indications as diverse as acute macular degeneration and pancreatic cancer, a growing number of cell therapies are driving toward pivotal clinical studies and commercialization. Although regulatory precedents have been set for various autologous and allogeneic products in the United States, Asia, and the European Union, regulatory guidance continues to evolve for a widening array of cell products. Adult stem cells (e.g., mesenchymal stem cells), embryonic stem cells,…

Essentials in Quality By Design

Quality by design (QbD) is a systematic approach to drug development. It begins with predefined objectives and emphasizes product and process understanding and process control, all based on sound science, data-based decision making, and quality risk management (QRM). As introduced by the US Food and Drug Administration (FDA), QbD brings modern drug development methodologies to chemistry, manufacturing, and control (CMC) teams working on biologics, pharmaceuticals, and vaccines. The innovations associated with QbD are not so much the development concepts (which…

Quality Risk Assessment and Management Strategies for Biopharmaceutical Companies

You’ve probably been hearing a lot about risk assessment in recent months. Indeed, some 15 times more articles have been printed referencing the concept over the past year relative to a 12-month period just three years ago. That truly represents a geometric progression. Unfortunately, very few authors have been able to disambiguate the different methods or provide insight into this time-tested, multiple-industry philosophy that at its core uses good science to make better decisions. When we undertake the challenge to…

Responding to Life Sciences Manufacturing Industry Guidance

Increasingly, life science manufacturing companies are applying technology to meet quality by design (QbD) goals. Organizations collect overflowing volumes of process data as part of programs designed to improve manufacturing variability and outcomes. Collecting valuable data is now an everyday task thanks to available software and process analytical technology (PAT) tools. The industry today, in fact, has focused so much on gathering data that it often has lost sight of an important fact: Data collection systems are valuable only if…

Managing Contamination Risk While Maintaining Quality in Cell-Therapy Manufacturing

With an increasing number of cell therapies becoming available for patient use, the need for controlled and consistent manufacturing and delivery of cell products is increasingly important. A closed cell culture process not only offers control and consistency, but may also relieve labor demands. Single-use components within a closed process also can reduce contamination risk. Closed systems with single-use platforms may reduce the risk of biological contamination and cross-contamination that could inadvertently be introduced into cell-culture processes. Such contaminants use…

Risk Assessment and Business Impact Analysis of the Supply Chain

In the United States, up to 40% of businesses affected by a natural or human-caused disaster never reopen (1). The biopharmaceutical industry is not immune from disasters of a dizzying variety. But biotechnology companies often put all their supply needs in one proverbial basket. Companies need to understand fully the ramifications of contingency planning for single product lines. Imagine having to set up distribution and shipping plans for multiple products with different environmental needs, for shipping to different markets, and…

Encouraging In-House Disclosures In a Whistleblower’s World

Compliance officials have a great deal to worry about. They are judged by results and loaded with stress over the latest changes in government guidance documents and internal budget pressures. They need to continually update their programs to stay abreast of those developments, including revisions that target in-house processes to encourage disclosures from whistleblowers. Failure to provide for such revisions places both a company and individuals at risk Whistleblower Protection Expanded and Includes Rewards In response…