Biopharmaceutical companies face a broad range of challenges when developing new large-molecule products, including Potential failures in the clinic or, even worse, an inability to manufacture because of an increase in the number of complex molecules in a company’s pipeline Under- or over-manufacture of a drug substance raw material because of demand uncertainty Limited access to right-sized capacity, driven by the bioprocess industry’s shift away from large-volume stainless steel tanks toward mid-scale bioreactors A company’s inability to find a manufacturing…

Industry Yearbook 2016-2017

Customized Roadmap: A Strategic Commercial Manufacturing Plan

The pathway from conception to regulatory approval and commercialization of a cell therapy is long, complex, and resource intensive. To help inform numerous decisions along the way, an effective commercial manufacturing strategy for a cell therapy should be built on the four principles of what PCT calls development by design (DbD): quality, cost of goods (COGs), scalability, and sustainability. Proactively implementing a DbD strategy does not force a cell therapy developer to make a large manufacturing investment early in a…

High-Performance Biopharmaceutical Contract Development and Manufacturing

Rentschler is a full-service contract development and manufacturing organization (CDMO) and one of the leaders in the industry. Focused on the development and manufacturing of biopharmaceuticals in mammalian cell culture, we support our global clients through to market approval of their products. Delivering successful projects allows us to make an essential contribution to the global availability of biopharmaceuticals. Thanks to many years of experience, the high quality of our consulting services, and our flexibility, we can react quickly and effectively…

Biopharmaceutical Development and GMP Manufacturing: Preclinical to Commercial Supply

Richter-Helm is a Hamburg, Germany–based contract development and manufacturing company with a proven 25-year track record, specialized in products derived from bacteria and yeasts. Count on us to flexibly provide a comprehensive range of services and customized solutions. Clients worldwide already have benefited from our commitment to good manufacturing practice (GMP) and total transparency. Our work focuses on recombinant proteins, plasmid DNA, antibody fragments, and vaccines. Our seasoned, 160-strong team supports you with process development, supply of products for clinical…

Vetter: A Strategic Partner Focused on Your Success

Vetter is an international specialist in the production of aseptically prefilled syringe systems, cartridges, and vials. We are a family-owned, independent company and do not manufacture our own drugs. Resources for Every Stage of Growth Vetter’s full portfolio of services includes dedicated resources for both clinical development and commercial manufacturing. In addition, we provide expert packaging technologies and solutions tailored to your product’s specific market needs. Vetter Development Service Planning for Success:

The Microbial CMO: Process Development and Manufacturing of Biologics

Wacker Biotech is “The Microbial CMO” — the partner of choice for contract manufacturing of therapeutic proteins using microbial hosts. Our service portfolio covers molecular biology, process and analytical development, and the GMP production of biologics for clinical trials and commercial supply. Founded in 1999 as a spin-off from the Hans-Knöll Institute in Jena, we are a 100% subsidiary of Wacker Chemie AG since 2005. The sites in Jena and Halle provide a complete range of services for the development…

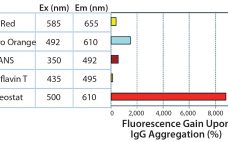

Optimize and Monitor Product Integrity

Development of a single drug, whether it is a new chemical entity, biotherapeutic, or cellular therapy, requires significant investment of resources. Care must be taken to choose analytical methods that are fit for the purpose of monitoring products and contaminants in the process. With expertise in labeling and detection, Enzo offers solutions to help rapidly analyze protein stability and integrity for all your bioprocessing needs. Protein Aggregation

Rapid Affinity and IgG Titer Analytics: Automating Bioanalysis with Gyrolab Nanoliter-Scale Technology

In the development of biotherapeutics, there is a need to quantitate antibody titer and to characterize antibody affinity against the target of interest. Such analyses are often challenged by the need for sensitivity, reproducibility, and higher throughput. Gyrolab systems automate and miniaturize affinity measurements and IgG titer quantification in a single platform using only nanoliter volumes with rapid time to results. IgG Titer Immunoassays with Broader Ranges for Cell Line Development

Rapid HCP Immunoassay Kit Selection: One HCP Kit Does Not Cover All Possible HCP Mixtures

Host cell protein (HCP) levels in biologics are on the critical path for assessing product quality, and they pose a serious risk to drug safety. The challenge is to accurately quantify a complex mixture of HCP impurities, which vary in properties and abundance depending on cell line, media, and process parameters. HCP immunoassay analysis is based on polyclonal antibodies raised against HCPs from nontransfected cell lines. How well a particular HCP assay recognizes all proteins depends on how well the…

Maximize Your Discovery and Development Productivity with Automated nanoDSF

Assessment of thermal stability parameters of biologics is an integral part of biopharmaceutical research. The ever-growing number of biologics in development pipelines worldwide demands rapid and precise methods to quickly screen large sets of conditions in an easy and straight-forward manner. In a recent study, we compared two methods for detection of thermal unfolding transition temperatures (Tm) of a therapeutic monoclonal antibody (MAb): nanoDSF, which analyzes changes in the fluorescence emission properties of proteins, and differential scanning calorimetry (µDSC), which…