Until relatively recently, life-science research was characterized by test tubes, Petri dishes, and centrifuges. Now, as with many industries, the life sciences are undergoing a digital transformation. Computational science is changing laboratory design. The healthcare industries always have generated large amounts of data. What has changed is the available information technology. With the growth of cloud computing, large data sets — and the high-speed tools for analyzing them — are available increasingly to a degree not possible with traditional servers…

Laboratory Equipment

Trends in Chemistry, Manufacturing, and Controls: Next-Generation Technologies and Product Modalities

New technologies bring new regulatory challenges. The biopharmaceutical industry must be cautious in its implementation of new scientific ideas and technology platforms — no matter how promising those might be. Regulators will look skeptically on any claim that isn’t backed up by good data, and with no solid history of successful use to build on, a company must have all the answers itself. How do compliance professionals anticipate what kinds of questions reviewers will ask when the time comes —…

Rapid Generation of High-Producing Clonal Cell Lines: Using FRET-Based Microfluidic Screening for Analysis, Sorting, Imaging, and Dispensing

Sales of monoclonal antibodies (MAbs) are predicted to be over US$125 billion by 2020 (1). Such revenue potential puts significant pressure on the biopharmaceutical industry to reduce timelines, especially to first-in-human trials. Cell-line development represents a large and critical portion of the early development timeline. Whether a developer is using random or targeted integration for introducing genes into a host-cell genome, the regulatory requirement for addressing monoclonality introduces a time and resource-intensive step in this process. Many different techniques are…

eBook: Bioprocess and Analytical Laboratories — Proving the Power of Data in Drug Development

Analytics pervade the entire biopharmaceutical development process — from protein characterization through biomanufacturing process optimization to final-product formulation and clinical testing. Every technical article in BPI requires data to back up the statements made, whether the topic is upstream/production, downstream processing, product development, or otherwise focused. And never mind publishing: Even more detailed documentation is required for regulatory submissions. If a company can’t back up the choices made and results obtained in development, manufacturing, and testing of its biopharmaceutical product,…

eBook: Bioinks for Bioprinting — Three-Dimensional Printing in Research and Medicine

Three-dimensional (3D) printing is one method of digital biomanufacturing for both basic biological research and translational, clinical applications. The medical field has used it to create such constructions as 3D surgical models for preoperative planning, to assist surgeons in their procedure preparations, which improves postsurgical outcomes. Examples here include generation of cleft-palate models (1), orthopedic applications (2), and cardiovascular surgical planning (3). Other forms of 3D printing for biological applications — such as 3D bioprinting — go beyond such surgical…

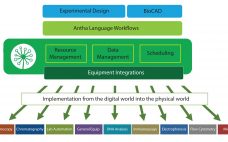

Accelerating Process Development Through Flexible Automated Workflows

Synthace began as a bioprocess optimization company in 2011, spun out of University College, London. The company worked on multifactorial approaches with 15–30 factors simultaneously instead of seven or eight. The work investigated genetic strain engineering factors alongside process parameters, defining deep interactions between the way strains were designed and the way they were treated in bioprocesses. Those complex experiments gave unique insight into the complexities of biological processes, but they were exceptionally taxing to plan and carryout manually. Automation…

CO2, O2, and Biomass Monitoring in Escherichia coli Shake Flask Culture: Following Glucose–Glycerin Diauxie Online

Carbon dioxide (CO2) is an important parameter in microbial cultures because it can inhibit or stimulate growth under certain conditions. In our experiment, we monitored Escherichia coli diauxie growth phases online and focused on dissolved CO2 (dCO2) and oxygen readings. We assessed diauxic growth in medium containing glycerin and glucose online with the SFR vario system (from PreSens), which optically measures oxygen, pH, and biomass in an Erlenmeyer flask. The shake flask contained an oxygen sensor spot and an optical…

BPI Lab: Essential Technologies for Development, Characterization, and QA/QC

There’s a secret hiding in plain sight: many analytical methods and technologies initially designed for pre-clinical development have equally important applications in commercial development. BioProcess International and BioTechniques, sister publications and leading journals that combined, cover the entire biopharmaceutical process, from discovery to development and manufacturing, partnered to create this special eBook, highlighting and detailing fourteen analytical technologies that provide laboratory technicians and scientists with vital information to help project managers and engineers make educated decisions that ultimately affect every…

Advancements in Characterizing Therapeutic Protein Higher-Order Structure

Electrospray-ionization mass spectrometry (ESI-MS) is a well-established tool for biotherapeutic analysis. It draws intact proteins or peptide ions into the vacuum of a mass spectrometer, where the ion mass is measured. Electrospray ion-mobility mass spectrometry (ESI-IMS) introduces ions into a low-pressure gas, where the effects of aerodynamic drag reveal their shape. This technique is just emerging as a valuable tool for characterizing intact proteins, even though for a decade it’s been the basis of a commercially available medical diagnostic test…

Enabling Faster Workflows with Protein Purification Technologies: Improvements in Chromatography and Electrophoresis

Purification of recombinant proteins is a critical step during protein therapeutics development. Protein therapeutics have a number of classifications based on their potential applications, including use as vaccines and diagnostics as well as for enzymatic, regulatory, or targeting activities (1). For all such applications, identifying and verifying protein purity is most important. Whether proteins themselves are therapeutics or the target proteins of interest, effective purification is essential in drug development. Since the introduction of recombinant proteins in the early 1980s,…