As a major class of emerging therapies, antibody-drug conjugates (ADCs) already have gained the attention of biopharmaceutical researchers and manufacturers because they combine both the precision of monoclonal antibodies and the potency of highly potent drug compounds. A few ADCs already have entered the market, but many more candidates are progressing through industry pipelines. Platform processes are not yet universal (and it remains to be seen whether they ever will be), but major ADC developers are establishing their own with…

Author Archives: Maribel Rios

Strategies for Successful Sample Transfer

Nadine Ritter is president and senior analytical advisor of Global Biotech Experts, LLC and a long-time member of BioProcess International’s editorial advisory board. At a recent CASSS North American CMC Strategy Forum called “Methods on the Move: Addressing Method Transfer Challenges,” she discussed the biopharmaceutical industry’s logistical challenges of analytical test samples for drug substances and products. At the conference, BPI’s editor in chief Anne Montgomery met with her to discuss some key points of this topic. Logistics Challenges Montgomery:…

Introduction: Process Issues in Cell, Gene, and Tissue Therapies

It’s hard to believe that just six years ago, BioProcess International published its first cell therapy supplement, which included just one article on “cell therapy bioprocessing” (1). At the time, most such processing was conducted in special clinical laboratories and academic institutions. As BPI continued to cover this relatively new segment of the biopharmaceutical industry, we heard more about “the product is the process” and “scale out instead of scaling up.” After many trials, errors, and milestones, regenerative medicine has…

Expansion Platform Components

I first met Chris Mach at the Biotech Week Boston conference in October. We discussed the challenges that biomanufacturers are facing in cell expansion, especially in three specific areas in scale-up systems. View the full article below – Login Required

3D Bioprinting Possibilities and Challenges

Three-dimensional (3D) bioprinting is the newest addition to the regenerative medicine family. Now within the industry dedicated to providing more personalized drug products, this new additive-manufacturing technology has the potential to truly focus on individual tissue repair and replacement. In a short period of time, 3D bioprinting has been applied in studies using bones, blood vessels, composite tissues, vascular grafts, tracheal splints, cartilaginous structures, heart tissue (e.g., two-valve heart), and vaginal organs (1). View the full article below – Login…

Outsourcing Trends in Biosimilars Development: A Discussion with Niall Dinwoodie (Charles River Laboratories)

No discussion about the future of the biopharmaceutical industry would be complete without assessing the impact of biosimilars. But such discussions no longer focus on whether biosimilars will enter the market, but rather when and how much market share will they take. The rapid progression of biosimilar candidates in company pipelines and the strong biosimilars research conducted by international organizations are strong indications that if your company is not already working within the biosimilars market, it may already be too…

Best Practices for Technology Transfers Across a Global Network: A Discussion with Patheon’s Paul Jorjorian

A strategic technology transfer plan is the touchstone of global biomanufacturing enterprise, especially for contract service providers that must meet the needs of customers located across several continents. Like their clients, contract development and manufacturing organizations (CDMOs) are facing shortened timelines and cost pressures. They are turning to their process engineers and technology transfer teams to ensure communication with sponsor companies and streamline the transfer of information and critical activities between process development (PD) and manufacturing. In his presentation at…

Bioreactor Manufacturing Platforms for Cell Therapies

As an increasing number of cell therapies move into late-phase trials, developers are considering innovative solutions to address scale-up and commercialization challenges. Many of their questions focus on the technologies and engineering strategies that will be needed to optimize their processes, especially bioreactors. At the January 2016 Phacilitate Cell and Gene Therapy World conference, Siddharth Gupta, a scientist at Lonza (Walkersville, MD), talked about the effects of upstream process decisions on product quality in his presentation “Bioreactor Manufacturing Platforms: So…

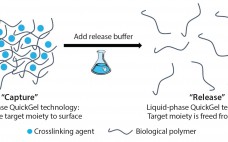

Development of a Novel Cell-Separation Platform: Discussion with Quad Technologies CEO Sean Kevlahan

Releasing and separating cells from surfaces and capture molecules are critical steps in cell therapy development. Research into such therapies as chimeric antigen receptor T cells (CAR-T) cancer therapies and stem-cell regenerative medicines demand the isolation and purification of viable and functional target cells. A number of cell-separation strategies can be used to produce such cells, but they are not able to deliver the required efficiency or scalability and can also cause damage to cells or affect their phenotype. Since…

Outsourcing Stability Testing: Discussions with Contract Laboratories

Stability testing is required for all biopharmaceutical drug products to detect all changes in identity, purity, and potency as a result of a number of environmental and processing factors. Whether testing is conducted in-house or through contact laboratories, it involves the development and performance of comprehensive and specific stability protocols for all stages of a product’s life cycle (1). Testing product stability in-house requires signficant time and resources, and carries challenges associated with commercialization market, time, and capacity. Market: The…