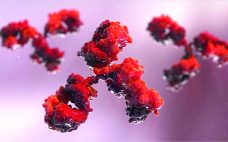

The therapeutic benefits of monoclonal antibodies (MAbs) have been demonstrated in recent decades with uncontestable success as treatments for human disease. Despite MAbs’ key features such as specificity, selectivity, and safety, the format has limitations (1, 2). Bispecific antibodies may overcome number of difficulties (3). Multiple formats of bispecific antibodies have been developed, although only the κλ-body is fully human and devoid of linkers or mutations. It requires no genetic modifications of heavy and light chains and results in bispecific antibodies…

Author Archives: Egbert Muller

Antibody–Drug Conjugate Surrogate Purification: TOYOPEARL® PPG-600M HIC Resin for DAR-Separation

Antibody–drug conjugates (ADCs) are promising biopharmaceuticals. They combine the high selectivity and affinity to cancer cells with the toxicity of chemotherapeutics in one molecule. ADCs consist of a monoclonal antibody covalently bound by a linker to a highly potent cytotoxic drug. ADC-surrogates contain a nontoxic payload with similar structure and physiochemical properties as the toxic payload of an ADC. Therefore, they can be used as models to develop suitable purification processes or analytical methods. The ADC-surrogate in this work consists…

Cost Estimation for Protein A Chromatography: An In Silico Approach to MAb Purification Strategy

Monoclonal antibody (MAb) production has adopted an accepted technology platform for downstream processing (1). The need for more economic processes has been addressed by increasing MAb titers in fermentation and aiming toward greater bioreactor volumes to increase productivity. Consequently, cost pressures are now passed on to downstream process groups. Membrane and chromatography resin savings are more important for MAb processes than ever before, with highly productive cell cultures generating large volumes of process fluid to purify (2). Traditionally, protein A…