Biologics represent a significant group of approved drugs, and they are expected to continue their exceptional growth in the foreseeable future. At first glance, innovative monoclonal antibodies (MAbs) and their derivatives seem to dominate the field; however, biobetters, biosimilars, and other therapeutic proteins have gained in relevance lately.

This diverse portfolio also is reflected in the range of different biomanufacturing processes used. Most blockbuster antibodies are produced by mammalian cells cultured in large bioreactors (10–20 m³) in fed-batch mode. But that has not always been the case. At the beginning of the biotechnology revolution, achievable expression titers were frequently <1 g/L. That usually was not sufficient to meet demand, so perfusion processes were applied to generate larger volumes over longer production intervals with constant exchange of reactor volumes of media while cells remain in their production vessel.

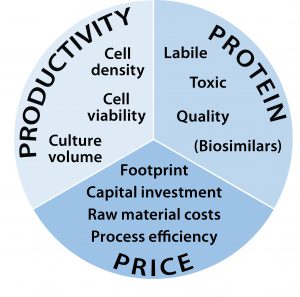

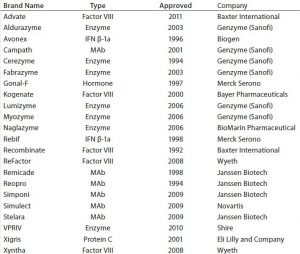

So far, about 20 biologic products manufactured in perfusion processes have been approved by the US Food and Drug Administration (FDA). Three molecule classes dominate this group: 30% are enzymes, 30% are antibodies, and 20% are coagulation factor VIII variants (Table 1) (1). It is worthwhile to assess the major factors that drive success, such as productivity, protein, and price — in the context of cost of goods supplied (CoGS) — as well as the opportunities and limits of continuous processing (Figure 1).

Drivers

Upstream Productivity: In the early days of biotechnology, cell lines did not deliver sufficient protein quantities, so an approach was required to generate more protein. A solution came with perfusion processes that kept cell counts constant while exchanging culture supernatants with fresh media in regular intervals, thus accumulating large volumes of product even with relatively low protein concentrations.

Low cellular productivity is still a key driver for current perfusion processes. Productivity gains also are related to the 10-fold higher viable cell concentrations that have become feasible now. In some systems, >100 Ă— 106 cells/mL can be achieved (2). Such high cell counts obviously generate higher product titers, but they also require media with sufficient nutrient content and/or high perfusion rates to exchange spent media quickly. A further benefit of perfusion cultivations is their generation of relatively homogeneous protein material that can be easier and more efficiently purified in downstream processing (DSP), thus raising overall yields.

The connection between up- and downstream processing is the critical cell-retention step. It should maintain a constant cell density in the bioreactor while separating off the product containing supernatant. It is important to use techniques that do not lyse cells by mechanical impacts or induce apoptosis through shear stress. That would cause an unwanted increase in process-related impurities such as host-cell proteins (HCPs) or DNA and would reduce viability.

Over the years, many different cell-retention approaches have been evaluated (3). All techniques share a common challenge; cells should remain outside the bioreactor for less than 10 minutes without supply of substrate and oxygen. In general, two different methods can be used: sedimentation and filtration. The former takes advantage of higher cell densities. Cells can be separated from cultivation fluid either by gravitational force in settlers or by centrifugal force in centrifuges or plate separators. Both approaches are time consuming and suffer from low volumetric throughput, which limits either reactor volume or perfusion rate. Centrifuges are technically complex systems that can be failure prone in long-term operations.

Filtration withholds cells depending on their size. Tangential-flow filters (TFF) and hollow fibers allow for sufficient flow rates. In long perfusion processes, membrane fouling and clogging have been observed, so a technology called alternating tangential-flow (ATF) filtration was developed. It reverses a feed stream through hollow fibers in regular intervals to wash off material that can block their pores (4). Instead of using a counterstream, filters also can be kept clean from a blocking layer by rotation. So-called spin filters are inserted into a bioreactor to enable continuous harvesting. Unfortunately, they cannot be replaced during operation because they are an integral part of a cultivation vessel (5).

An early potential solution to the problem of fouling was replacement of filters as physical barriers by use of acoustic waves that forced cells to aggregate until they settle under the influence of gravity (6). Other contact-free cell-retention devices rely on fluid dynamics in a hydrocyclone, a simple instrument that is basically free from moving parts. It induces a cyclone only through its fluid chamber design and allows very fast cell removal (7).

An ideal cell-retention device would demonstrate high-efficiency separation of cells from their medium with sufficient differentiation between dead and viable cells (8). All those diverse options must be assessed carefully with regard to their ability to work uninterrupted for several weeks. Figure 2 is a schematic overview of available cell-retention devices.

Downstream Processing: It is much more complicated to operate DSP continuously because it consists of a sequence of steps, each typically using only a fraction of the material from the previous step. To obtain a fully integrated DSP, ideally no intermediates would be generated requiring conditioning or fractionation. Unfortunately, the vision of a process relying only on flow-through chromatography is relatively unrealistic, particularly for purifying complex proteins that don’t benefit from a platform process like that for MAbs based on protein A affinity.

However, in recent years a number of chromatography unit operations have been developed for continuous processing. Most rely on the concept of spatially separating steps such as loading, washing, elution, and regeneration on individual columns. The columns can be run in parallel or sequentially, and the simplest variant uses a single column for each step.

Most new methods benefit from an improved use of column capacity achieved by loading the first column completely and then switching the load directly to the next column to saturate its capacity. Then the first column is consecutively washed, eluted, and regenerated. Moving stationary (columns) and mobile (buffer) phases in opposite directions is called countercurrent chromatography. Many different variants have been described: e.g., periodic countercurrent (PCC), simulated moving bed (SMB), and sequential multicolumn (SMC) chromatography (Figure 3). At least two columns are required. This simplified principle works best in affinity chromatography, such as with MAbs and protein A — in which no peak-cutting or fractionation is required. More complex mixtures can be separated in more sophisticated setups (9).

The key performance indicator for every chromatography process is purity, which implies reaching certain quality specifications and overall efficiency in terms of yield and throughput. Purity is defined as the final pure product output in relation to resin volume used, number of cycles, or time. If the output per cycle increases — as in the case of better capacity use — then buffer consumption decreases. Costs are also lowered if the lifetime of a column is used maximally, which is the case with most continuous chromatography techniques (10).

Continuous-countercurrent tangential chromatography (CCTC) uses a series of hollow fibers, static mixers, and loose resin slurry for purification. The whole system is composed of disposable materials. Without packed columns, smaller particles and much faster mass-transfer rates can be used without inducing high counterpressures. Because all steps are performed in solution, further modifications such as conditioning and concentration by single-pass TFF easily can be added (11).

The biggest driver and benefit for continuous chromatography is minimized footprint and maximized use of column capacity and lifetime, as well as reduced buffer consumption, which can save on both capital investments and raw material costs.

Protein and Quality: A strong reason for adopting continuous upstream processing is the ability to remove potentially toxic metabolites that can limit cell growth and viability or affect protein quality. Maintaining a constant nutrient level resembles the natural environment of cells in an animal’s bloodstream, thus causing less stress for sensitive cells. Removal of labile proteins from culture broth eliminates their risk for degradation, and removing potentially toxic proteins supports cell viability.

So on one hand, protein products can be protected from cells; on the other hand, cells can be protected from expressed proteins. Both effects are advantageous for producing labile enzymes and coagulation factors as well as interferons, which affect cell viability. In the case of interferons, perfusion helped to improve product quality as well when shorter culture residence times and lower titers suppressed aggregation while improving productivity of cultivation (12).

Biosimilar developers also could benefit from continuous processes. The goal of biosimilar development is to match the critical quality attributes (CQAs) that define the characteristics of an originator product. In a traditional fed-batch process, a mixture of protein isoforms derived from different culture stages need to be separated or mixed so as to obtain the proper target profile of the drug to be reproduced. That can be achieved through perfusion by maintaining constant, steady-state culture conditions that lead predominantly to the production of a desired target profile.

Unacceptable product quality — e.g., at the beginning or end of a process — is a nonissue because such harvests can be eliminated from perfusion process streams. This has been demonstrated recently in a perfusion process for a rituximab biosimilar (13). The opposite approach works as well: Replacing an old-fashioned perfusion process with a modern fed-batch process provided comparable product quality (14).

Modulating viable cell density (VCD) in a perfusion bioreactor is one way to influence quality attributes such as aggregates, fragments, charge isoforms, and N-linked glycosylation — as demonstrated in a case study with a standard antibody (15). But not only product quality is affected by USP conditions. In an example with a coagulation factor, fast capturing from a perfusion culture with high-volume exchange rates on membrane absorbers improved product quality significantly (16).

Cost: A number of studies have investigated the economic benefit of establishing continuous processes. In a recent analysis comparing fed-batch and continuous platform processes for antibody manufacturing, the authors report that for a 200-kg/year drug substance capacity, the specific CoG for 1 g was €84 in a continuous process and only €59 from fed-batch cultivation (17). The underlying reasons become apparent when they separated upstream and downstream processes. Continuous USP was 33€/g more expensive because of high media costs; continuous DSP was €8/g less expensive than the batch process. The latter benefit was derived primarily from the improved use of chromatography resins. Consequently, the largest savings could be achieved by combining fed-batch USP with continuous DSP, thus reducing the overall CoGS per gram of antibody down to €50 (17).

Another study modeling an integrated continuous bioprocessing (ICB) platform resulted in 55% cost savings, including capital investment and operating expenses for the continuous process compared with traditional fed-batch. Both achieved identical outputs (18). This model is based on different reactor dimensions and numbers for continuous and conventional processes. For the ICB mode, several 500-L disposable reactors are used; for fed-batch antibody production, two 10,000-L stainless steel bioreactors, and for nonantibodies a six-pack of 2,000-L reactors are used (18).

Comparing fed-batch, spin-filter perfusion, and ATF perfusion cultivation revealed a 20% CoGS savings benefit over traditional fed-batch under the assumption that a fivefold higher cell density could be achieved (19). However, the fed-batch process was more environmentally sustainable because of lower water consumption.

In general, it can be stated that much of the cost advantage from continuous processes comes from smaller equipment footprints (compared with batch and fed-batch systems) and consequently lower capital investments. Smaller facilities are easier to expand or replicate as backup at multiple sites. With the help of smart batch definitions, scale-up could be enabled simply by extending the duration of a perfusion process. Capacity use is improved when only a small number of long perfusion campaigns are performed, reducing the number of product change-overs. However, that limits the degree of flexibility a company has to switch quickly between different products. Further process-related benefits can be derived from a better resin capacity use and column lifetime exploitation, which is particularly important when expensive protein A resins are involved.

Opportunities

High output from a relatively small footprint presents a significant opportunity for single-use equipment that otherwise has some inherent scale limitations. Smaller sized and less-complex installations further emphasize the cost advantage of continuous processing. But it should not be ignored that continuous DSP systems are typically more complicated than batch systems, having more valves installed. All the necessary building blocks for a fully disposable continuous value stream do exist: bioreactors, cell-retention devices, prepacked columns, and filters (20).

Particularly in DSP, many opportunities are available for establishing and optimizing a continuous process. Sometimes it might be advisable to focus on only the one unit operation that will be easy to implement and have the biggest impact. Many companies are performing continuous capturing, for example, while maintaining a collective polishing campaign. This is a common approach in antibody capture to optimize the use and cost of expensive protein A resins.

Continuous processing also could be the production method of choice for biosimilars, with their price-sensitive manufacturing strategies. Such products could benefit from all the above-mentioned cost advantages while potentially delivering the right quality target product profile (QTPP) with less effort. For some biosimilar markets in developing countries, it also might be relevant to locate production facilities in proximity to the markets, which could easily be enabled by less complex single-use facilities running continuous processes. The maximum benefit might be achieved with complete integration of USP and DSP in a fully continuous process (21).

The FDA appears to be a strong supporter of continuous bioprocessing because it reduces manual interference with product streams and improves process control (22). In that context, the agency also recommends using quality by design (QbD) principles to establish sufficient process robustness. However, it is still challenging to establish proper scale-down models, which are prerequisite for that approach.

Limits

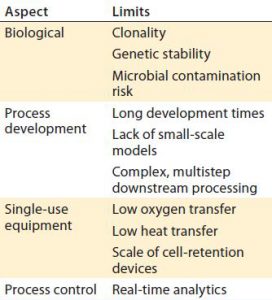

It could be argued that the benefits of continuous processing outweigh its constraints. That is not really true, however. Some limitations such as the low level of facility flexibility with long run times are inherent to continuous operations. Other challenges include the difficulty of setting up valid scale-down models and the long duration of process development. Furthermore, biological problems connected to genetic instability of cells or their lack of clonality can have a more negative impact here than in fed-batch cultures. In some cases, a risk for microbial contaminations has been observed during long-term operations. Nowadays that is better manageable through tube welding that creates fully closed systems for safe sampling.

The traditional approach for blocking in-process controls (IPCs) to release the intermediates to the next step (including waiting time for assays to be performed outside a production suite) does not apply in a continuous setting. The demand is for fast, ideally inline process analytical technology (PAT) that delivers results immediately and can be used for (semi)automated process control. Therefore, control strategy is an important topic that is yet to be explored fully. It includes the definition of sampling frequency when inline monitoring is not feasible.

In addition to monitoring standard parameters such as pH, temperature, and dissolved oxygen (DO), it would be very useful to obtain real-time information on cell concentration and viability, major nutrients, and metabolism byproducts. Dielectric spectroscopy (DS) and near-infrared spectroscopy (NIRS) have been applied recently for that purpose (23). Raman spectroscopy is a very promising method for studying the presence and concentration of a broad range of cell-culture–relevant molecules such as glucose, glutamate, glutamine, lactate, and ammonia, along with cell concentration and viability. It provides fast results to enable real-time process control. However, instrument calibration may present some difficulty (24).

At some point the DO level might become a limiting factor for high cell densities in single-use bioreactors. In such cases, it cannot be further increased because of oxygen transfer rates as well as pressure limits of the plastic bags’ welded seams. A high cell concentration also generates heat that is difficult to transfer across insulating plastic layers. For very high cell densities, therefore, disposable bioreactors are not recommended. Table 2 lists these major limitations.

A continuous biomanufacturing process has an endpoint. This is partly related to cells and their genetic stability over long periods, a contamination-free handling, and the ability of instrumentation for reliably performing many cycles. Regardless of the ultimate endpoint, a “batch” must be defined: Is it every single exchanged harvest volume, or is it more related to the final bulk drug substance? This is an important consideration because it affects responses to potential process interruptions that can endanger entire production campaigns — or only single harvests — and their related drug substances.

One Size Does Not Fit All

The biotech industry seems to be at a crossroad. New entrants to bioprocessing (e.g., Samsung) are erecting huge traditional fed-batch facilities using stainless steel to support the biosimilar wave. Meanwhile, corporations with decades-long experience in bioprocessing are moving to the next step in industrialization. For example, Genzyme (Sanofi) is using insights derived from manufacturing difficult enzymes with perfusion cultures to establish end-to-end, integrated, fully continuous production of recombinant MAbs (21). Some suppliers are focusing their product lines toward continuous processes, offering solutions to all steps from single-use bioreactors and settlers to SMB chromatography skids (25).

However, we must take into account the above-mentioned benefits and limits of continuous processing to decide which approach to select for a given application (26). Figure 4 summarizes the critical parameters. Continuous processing is the method of choice for sensitive, complex biologicals. But for stable mass products such as antibodies, the cost savings of continuous downstream can be realized only as long as the prices for protein A or similar capture resins remain high.

References

1 Boedeker BGD. Production Processes of Licensed Recombinant Factor VIII Preparations. Semin. Thromb. Hemost. 27, 2001: 385–394.

2 Clincke M-F, et al. Very High Density of CHO Cells in Perfusion By ATF or TFF in WAVE Bioreactor, Part 1: Effect of the Cell Density on the Process. Biotechnol. Prog. 29, 2013: 754–767.

3 Henzler H-J. Kontinuierliche Fermentation mit Tierischen Zellen, Teil 2: Techniken und Methoden der Zellrückhaltung. Chemie Ing. Tech. 84, 2012: 1482–1496.

4 Kelly W, et al. Understanding and Modeling Alternating Tangential-Flow Filtration for Perfusion Cell Culture. Biotechnol. Prog. 30, 2014: 1291–1300.

5 Deo YM, Mahadevan MD, Fuchs R. Practical Considerations in Operation and Scale-Up of Spin-Filter Based Bioreactors for Monoclonal Antibody Production. Biotechnol. Prog. 12, 1996: 57–64.

6 Trampler F, et al. Acoustic Cell Filter for High-Density Perfusion Culture of Hybridoma Cells. Biotechnol. 12, 1994: 281–284.

7 Pinto RCV, Medronho RA, Castilho LR. Separation of CHO Cells Using Hydrocyclones. Cytotechnol. 56, 2008: 57–67.

8 Voisard D, et al. Potential of Cell Retention Techniques for Large-Scale HighDensity Perfusion Culture of Suspended Mammalian Cells. Biotechnol. Bioeng. 82, 2003: 751–765.

9 Jungbauer A. Continuous Downstream Processing of Biopharmaceuticals. Trends Biotechnol. 31, 2013: 479–492.

10 Steinebach F, Müller-Späth T, Morbidelli M. Continuous Counter-Current Chromatography for the Capture and Polishing Steps in Biopharmaceuticals Production. Biotechnol. J. 11, 2016: 1126–1141.

11 Dutta AK, et al. Performance Optimization of Continuous Countercurrent Tangential Chromatography for Antibody Capture. Biotechnol. Prog. 32, 2016: 430–439.

12 Rodriguez J, et al. High Productivity of Human Recombinant Beta-Interferon from a Low-Temperature Perfusion Culture. J. Biotechnol. 150, 2010: 509–518.

13 Dorvignit D, et al. Expression and Biological Characterization of an Anti-CD20 Biosimilar Candidate Antibody: A Case Study. MAbs 4, 2012: 488–496.

14 Meuwly F, et al. Conversion of a CHO Cell Culture Process from Perfusion to FedBatch Technology Without Altering Product Quality. J. Biotechnol. 123, 2006: 106–116.

15 Karst DJ, et al. Process Performance and Product Quality in an Integrated Continuous Antibody Production Process. Biotechnol. Bioeng. 114, 2017: 298–307.

16 Vogel JH, et al. A New Large-Scale Manufacturing Platform for Complex Biopharmaceuticals. Biotechnol. Bioeng. 109, 2012: 3049–3058.

17 Klutz S, et al. Cost Evaluation of Antibody Production Processes in Different Operation Modes. Chem. Eng. Sci. 141, 2016: 63–74.

18 Walther J, et al. The Business Impact of an Integrated Continuous Biomanufacturing Platform for Recombinant Protein Production. J. Biotechnol. 213, 2015: 3–12.

19 Pollock J, Ho SV, Farid SS. Fed-Batch and Perfusion Culture Processes: Economic, Environmental, and Operational Feasibility Under Uncertainty. Biotechnol. Bioeng. 110, 2013: 206–219.

20 Jacquemart R, et al. A Single-Use Strategy to Enable Manufacturing of Affordable Biologics. Comput. Struct. Biotechnol. J. 14, 2016: 309–318.

21 Godawat R, et al. End-to-End Integrated Fully Continuous Production of Recombinant Monoclonal Antibodies. J. Biotechnol. 213, 2015: 13–19.

22 Yu L. Continuous Manufacturing Has a Strong Impact on Drug Quality. FDA Voice 12 April 2016; http://blogs.fda.gov/fdavoice/index. php/2016/04/continuous-manufacturing-has-a-strong-impact-on-drug-quality.

23 Mercier SM, et al. Process Analytical Technology Tools for Perfusion Cell Culture. Eng. Life Sci. 16, 2016: 25–35.

24 Esmonde-White KA, et al. Raman Spectroscopy As a Process Analytical Technology for Pharmaceutical Manufacturing and Bioprocessing. Anal. Bioanal. Chem. 409, 2017: 637–649.

25 Levison P. Moving One Unit Operation at a Time Toward Continuous Biomanufacturing. BioProcess Int. 14(6) 2016: S6–S9.

26 Croughan MS, Konstantinov KB, Cooney C. The Future of Industrial Bioprocessing: Batch or Continuous? Biotechnol. Bioeng. 112, 2015: 648–651.

Dr. Stefan R. Schmidt is senior vice president of process science and production at Rentschler Biotechnologie, ErwinRentschler-StraĂźe 21, 88471 Laupheim, Germany; 49-7392-7010; stefan.schmidt@rentschler.de; www.rentschler.de.