This webcast features: Fletcher Malcom, Product Line Leader – Chromatography, Repligen Ceramic hydroxyapatite (CHT™) resins are used in processes where unique selectivity is desired for purification of mAbs or recombinant proteins. Until recently, shipping columns pre-packed with CHT™ resin provided challenges due to the fragile nature of the chromatographic bed. To overcome these challenges, Repligen has developed a proprietary packing method for CHT™ resins which maintains chromatographic performance during transit. In this presentation, packing performance and shipping validation data will…

Thursday, September 26, 2019 Daily Archives

Scalable Purification Strategies for Viral Vectors and Vaccines

This webcast features: Mark A. Snyder, Ph.D., R&D Manager, Process Chromatography Applications, Bio-Rad Laboratories Large-scale downstream processing of viruses can face a range of obstacles different from those of many biotherapeutics. These challenges mostly arise from the size and complexity of the virus, which can affect product purity and recovery. Improvements of purification tools are necessary to overcome these challenges and must be engineered for easy scalability to meet manufacturing demands. Dr. Mark Snyder will discuss the difficulties when developing…

The Impact of Rapid Virus Quantification in the Development and Manufacture of Advanced Therapies

This webcast features: Antje Schickert, Product Manager, Virus Analytics, Sartorius Stedim Biotech Viral vectors, such as lenti- and adeno-associated viruses, are increasingly being used for the production of cell and gene therapies. In-depth sample characterization and precise enumeration of total viral vectors is needed throughout the manufacturing process and particularly for the final formulation. Learn how rapid accurate enumeration of the total virus provides timely information on titer leading to accelerated process development and increased efficiency of viral vector manufacturing.…

Introduction: Reporting from the Frontiers of Cell Line Engineering at BPI Europe and BPI West

Every biomanufacturing process begins with transfection of recombinant genes into pools of cells — followed by a succession of screenings from which will emerge (ideally) a single progenitor cell of the new production cell line. Cast aside will be those cells that do not uptake the correct genetic material, those incapable of thriving in bioprocess conditions, those that fail to produce recombinant protein at relevant levels, and those without demonstrated clonality and relative genetic stability. Over the past several years,…

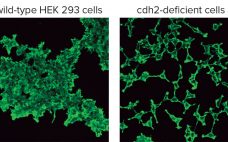

Creating Novel Cell Lines By Genome Editing: Simplifying Cell-Based Assays and Improving Production of Biomolecules

Cultured cell lines have a diverse range of applications. They are used broadly by cell biologists, clinicians, tissue engineers, biotechnology scientists, and bioengineers. The most important uses of cell culture are in the cell-based assays and production of biologically active recombinant proteins. In recent years, genome editing has been used widely to study the structure, function, and localization of endogenous proteins in cultured cells. However, applying the same genome editing techniques to cell lines also could improve the propagation of…

Streamlined Serum-Free Adaptation of CHO-DG44 Cells: Using a Novel Chemically Defined Medium

Monoclonal antibodies (MAbs) have radically transformed the treatment of many chronic diseases, mainly in the fields of oncology and autoimmunity. The overwhelming majority of therapeutic MAbs are manufactured from recombinant Chinese hamster ovary (CHO) cell lines. The original CHO cell line was isolated in the 1950s, and since the early 1980s, it has become the workhorse of the biopharmaceutical industry. The CHO-DG44 strain was generated after several rounds of mutagenesis that deleted both copies of dihydrofolate reductase (dhfr) genes by…

eBook: Autologous Cell Therapies: Commercialization Strategies

Autologous cell therapies are derived from a patient’s own stem cells, typically collected from bone marrow. Those cells are then cultured, expanded, and reinfused back into the patient. Unlike allogeneic cell therapies, this process is repeated for each dose and for one patient. The one-to-one process carries several challenges to commercialization, including high development costs, the need to control the risks of manual processing, and compliance with strict timelines. This eBook presents two perspectives on addressing these challenges. The first…

Bavarian Nordic gets FDA tick for monkeypox vaccine

Jynneos has become the first vaccine to be approved for non-replicating smallpox in the US and monkeypox in the world. The US Food and Drug Administration (FDA) has given Danish drugmaker the go ahead to manufacture and supply the liquid-frozen suspension of its vaccine Jynneos for smallpox and monkeypox in adults aged 18 years and over. The approval is “the culmination of a fifteen-year partnership that started with a call from the NIH [National Institutes of Health] for a safer…