In an October webcast, Vironova’s Josefina Nilsson (head of electron microscopy services) and Gustaf Kylberg (MiniTEM product manager) discussed subvisible particle characterization using the MiniTEM system, which provides both morphology and quantitative data.

In an October webcast, Vironova’s Josefina Nilsson (head of electron microscopy services) and Gustaf Kylberg (MiniTEM product manager) discussed subvisible particle characterization using the MiniTEM system, which provides both morphology and quantitative data.

Nilsson and Kylberg’s Presentation

Vironova combines expertise in electron microscopy and image analysis with in-house designed software. Electron microscopy is a good technique for getting to know your product in detail (morphology and other characteristics). After discussions with partners and clients, Vironova worked with Delong Instruments to develop the tabletop MiniTEM transmission electron microscope.

Undesired outcomes can occur during biopharmaceutical development, manufacturing, and storage: e.g., aggregate formation, failure to remove host cell debris, and loss of particle morphology or integrity. Electron microscopy can show you whether such outcomes are occurring.

By contrast with a conventional electron microscope that requires a highly skilled expert user in a laboratory with complex infrastructure, the MiniTEM system is designed for generalists. It requires neither the infrastructure nor voltage of a conventional system; it is powered by an ordinary 230/110 V wall socket. You can place it in an ordinary laboratory setting. Ease of use comes with the instrument’s small size and intuitive software that enables automation.

This instrument provides a direct imaging method that also measures size distribution and thus has an advantage over indirect methods such as dynamic light scattering (DLS). Vironova compared DLS and MiniTEM particle-size analysis of an adenoassociated virus (AAV) sample. Whereas DLS analysis showed a broad peak, the MiniTEM system showed more detail, with two distinct peaks denoting two distinct classes of particles.

One benefit of the MiniTEM system is that it is not a “black box.” If you get unexpected results, you can look at the structures behind those results to see what actually happened. You can see how particle morphology and integrity have been affected, something that often can be correlated to the efficacy and stability of the product.

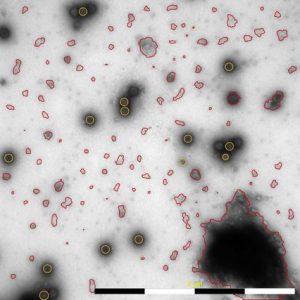

For investigating morphology, individual images may be examined; for quantitative measures, a number of images must be acquired to measure a large number of particles and objects. A MiniTEM instrument does so by automating image acquisition and analysis. To get robust quantitative measurements, the system analyzes hundreds of images and tens of thousands of particles. For measuring purity and level of debris, Vironova looked at ratios of distribution.

The high degree of automation makes analysis fast. Vironova compared automated analysis with the manual alternative by manually analyzing 20 images and extrapolating the time it would take for 200 images. The MiniTEM system takes <10 hours, whereas using conventional EM with manual analysis would take nearly 80 hours.

The MiniTEM system provides data characterization on biopharmaceutical products in early development to support both formulation and production processes.

Questions and Answers

How are liquid samples analyzed with a MiniTEM system? We take a small volume of a liquid sample (about 3 μL) and put it on a sample grid, then add staining and let it dry before running the analysis. This process takes ~15 minutes.

Can you comment on the footprint size of the instrument? Is it intended to be a benchtop instrument, or does it sit on the floor? The current set-up is for a table. Some control electronics are below the table, and a small unit stands to the side of the table, with the screen and computer on the table. But an even more compact design also is possible.

Can the system be used for pigment particle analysis? If pigment particles are in the nanometer size range, then it should be possible. It depends more on the electron density of the particles.

Is the system capable of analyzing the purity of influenza virus particles? Yes, we have experience with influenza particles. It would work fine.

How much sample volume is needed to perform an analysis? The sample is put on a grid that takes only 3 μL, which is a small droplet.

Are specimens negatively stained? Yes, they are usually negatively stained, but you can run it even without stain for some specific applications.

What is the microscope’s resolution? It measures to just below 1 nm.

More Online

The full presentation of this webcast can be found on the BioProcess International website at www.bioprocessintl.com/ask-the-experts/reveal-information-gives-insights-new-approaches-sub-visible-particle-characterization.