Over the years, the BioProcess International special supplements have tackled a large number of important topics on emerging trends and new technologies in biomanufacturing, including single-use technologies, continuous manufacturing, cell therapies, and outsourcing. As these and other issues continue to arise and play a critical role in the development of the biopharmaceutical industry, the success of the biomanufacturing industry relies on its ability to attract and retain a well-trained and motivated workforce that can adapt to new technologies and manufacturing…

Tuesday, December 20, 2016 Daily Archives

Advancing the Biopharmaceutical Community Through Learning and Development Partnerships

As in most high-tech sectors, success within the highly regulated biopharmaceutical manufacturing industry depends upon an adaptable, skilled, educated, and high-performing workforce. The impact of human performance cuts across the entire industry — whether for a manufacturing operator, a scientist or engineer in a highly technical role such as process development, or a technical sales representative serving the industry. The effects of poor performance can be seen easily in deviation reports and FDA warning letters as well as in quantified…

Designing In-House Training Programs: Moving Beyond Read and Understand

To begin the discussions in this issue about structuring successful training programs, these authors describe how to develop in-house resources. Both emphasize the need to assess the impact of previous training approaches. An important factor is to understand that students will bring varying levels of knowledge and relevant experience to their work with your company. So how do you structure a training program that takes into account individual learning styles and operational expertise? How to you measure the successful application…

Training for New and Emerging Technologies: Building Comprehensive, Process-Oriented Competencies

Assessing the need for training that addresses the varied needs of your employees requires looking far beyond a one-size-fits-all approach. Few companies, however, have the internal resources to develop truly comprehensive programs on their own. Successful training approaches are those that enable end-users, organizations, and suppliers to share needed equipment and expertise. At the 2016 BioProcess Theater at Interphex, Gary Gilleskie (BTEC’s director of operations) and Scott Sommer (a technical fellow at Renmatix) detailed examples of successful training programs for…

Measuring the Impact of Investments in Professional Development: A Virtual Roundtable

Well-designed education, training, and professional development programs and partnerships add considerable return on investment to stakeholders across the biopharmaceutical manufacturing industry. As biomanufacturers, suppliers, and regulatory bodies share similar workforce needs, focused education and training efforts can lead to increases in productivity, yield, and employee engagement and retention. In addition, education and training programs can decrease the incidence of deviations, which are costly to investigate and remediate. Yet when compared with other business needs, training, development, and human performance initiatives…

Exploring Academic Models for Biomanufacturing Education

Undergraduate and/or graduate programs in physical and life sciences can provide a solid background for science and engineering students who are interested in careers in biotechnology research and development. Yet many such programs have not adequately prepared students for careers within and related to the biopharmaceutical industry. In today’s globally competitive job market, developing a workforce pipeline for the bioprocess industry requires academic programs that equip students with knowledge, skills, and theory surrounding the equipment, methodologies, processes, and regulatory requirements…

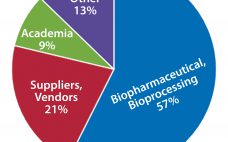

Demographics and Trends: Results from a Joint BPI/BTEC Survey on Training

Training is an investment. And it’s one that the authors, contributors, and other individuals behind this supplement understand well. However, the biopharmaceutical industry is much larger than these few individuals. It’s just as important to understand the motivators, drivers, and training-related challenges faced by the industry at large. So BPI and BTEC jointly administered a short survey to gather some basic information from the magazine’s readership about the value and role that training plays in their organizations. According to survey…

A Scalable Immobilized Metal Affinity Chromatography Resin for Process Purification

Downstream process purification of proteins requires a resin with optimized bead size for ideal pressure/flow properties and decent dynamic binding capacity (DBC) that provides production efficiencies and good process economics. Our newly developed metal chelate affinity resin — Nuvia™ IMAC — provides the mechanical strength, pore structures, ligand density, and particle size distribution required for an operation run at 300 cm/hr with a DBC of > 40 mg/ml at < 2 bar column backpressure. Protein purification can efficiently be scaled…

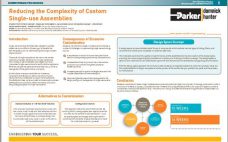

Reducing the Complexity of Custom Single-Use Assemblies

Single-use technology (SUT) has been adopted on a global scale since its introduction 20 years ago. Its benefits are well-recognized, and it is a key enabling technology in today’s biopharm world. Thousands of single-use products are now on the market and entire processes are being run in single-use systems. Historically, end users have been encouraged to produce ‘customized’ single-use solutions for each individual application. While this can give the user exactly what they want, it can be at the expense…

New Agarose-Based Protein A Resins Designed for Cost Effective Purification of MAbs

It is well recognized that the cost of Protein A resins is substantial. If a product makes it to marketing approval and manufacturing the high cost is amortized over a large number of purification cycles then the contribution to cost of goods is acceptable. However, a high percentage of clinical projects will fail and the Protein A resin will only be used for a small number of cycles. One way to address this issue is to use a less expensive…