It’s official: The “Age of Cell Therapy” has arrived. A robust pipeline of cell therapies, with increasing numbers of both early- and late-stage clinical trials as well as FDA-approved commercial products that have entered the market already, strongly indicates that the cell therapy industry is poised to emerge as a distinct healthcare sector (1). Renewed investor interest and recent activity among major pharmaceutical companies suggest that this industry will rapidly develop the capability and capacity to be a highly competitive, sustainable, multibillion-dollar enterprise. But when commercialization comes, will companies be ready to meet the enormous demand for viable cells?

PRODUCT FOCUS: C

The maturing field of automated cell cultivation using highly specialized bioreactor designs and stringent bioprocess controls will be crucial for the development of biomanufacturing technologies suitable for clinical-grade production of future cytotherapeutics. However, unlike well-established therapeutic modalities (pharmaceuticals, biopharmaceuticals, and medical devices), the broad spectrum of highly diverse cell therapies in development requires a customizable manufacturing platform that is flexible enough to accommodate bespoke cellular designs yet rigorous enough to consistently produce a complex, viable product: living cells. As for those widely integrated pillars of medicine, however, the unique core competencies and underlying scientific principles of platform technologies used in manufacturing cell-based products will ultimately define their potency, purity, stability, efficacy, safety, and quality. In addition to other special challenges (e.g., constraining the innate protean nature of polymorphically active cells, assessing the variableness of their multipotencies, and tracking highly personalized medicines), creatively addressing manufacturing-related issues is key for successful bioengineering of cell products at an industrial scale.

As in other biotechnology applications such as the mass production of therapeutic antibodies or live-attenuated virus vaccines, bioengineered cell therapies will critically depend on bioreactor-based manufacturing systems (2). Intended as a means to create and maintain a controlled physiochemical culture environment, bioreactors represent a key element for the automated, standardized, traceable, cost-effective, safe, and regulatory-compliant manufacture of cell-based products for clinical applications.

The realization that industrializing the cell therapy industry will require pioneering manufacturing systems has promoted interactions among scientists, engineers, clinicians, and business professionals to create devices that will facilitate the transfer of academic-level, cell-based processes into clinically and commercially viable solutions. Companies need to translate highly individualized culture protocols developed by research laboratories into validated, streamlined bioprocesses that can guarantee reproducibility, scalability, standardization, robustness, and safety. It has become increasingly apparent that success will rely on the development of scalable and robust bioreactor devices, design of flexible culture strategies, and monitoring and control of culture environments.

Clinical Need for Scaled Cells on DemandMost existing FDA-approved cell therapies typically use minimally manipulated cells. Preferably, they are harvested from an individual patient and subsequently returned to the same patient as an autologous transplant. Alternatively, cells from matched donors can be administered as allogeneic transplants. Because harvested cells in many instances are not expanded ex vivo before transplantation, the use of sophisticated systems for their large-scale culture has been unnecessary until the past couple years. But in many recent clinical trials, efficacy has been shown to be related to cell dose, highlighting the need for large numbers of cells. For many newly developed cell therapies, the number of cells needed to effectively treat patients greatly surpasses the number of cells available from donors. In fact, a shortage of procured tissues for even standard medical procedures has driven the clinical community to seek alternative cell sources, greatly accelerating recent growth in the cell “manufacturing” industry.

Moreover, development of new cell-based regimens for cancer treatment (e.g., adoptive T-cell therapies and dendritic cell vaccines) requires a large number of specialized immune cells to be expanded ex vivo from a small number of harvested cells. That requirement has spurred development of culture technologies that allow for robust, cost-effective, and systematic production of specific cells. For now, medium-scale systems such as standard roller bottles and multitiered flasks (with or without perfusion modules) have provided adequate cell numbers for such applications, but the technology will be limiting as clinical demand increases.

The advent of robotically controlled equipment such as TAP Biosystems’ SelectT and CompacT systems has been a step in the right direction. They significantly reduce both the amount of laborious manual intervention and the possibility of contamination while increasing the consistency of generated cell products. But for more complex cell products and those that require larger-scale manufacturing, even those will be inadequate.

A need to develop even more fully controlled large-scale bioreactor platforms and closed systems has arisen not only from the limited number of cells that can be obtained from patients or donors (even with current state-of-the-art automated expansion methodologies), but also from the need to comply with strict regulations. Because cells are the desired products, further challenges in compliance with current good manufacturing practice (CGMP) and product safety also need to be overcome. Donor variability, microbial contamination, and potential tumorigenicity of highly replicative cells are examples of issues that must be considered during cell manufacturing for clinical applications (3).

Manufacturing Stem Cells at ScaleCurrent developments in cell bioprocessing have focused on identifying essential requirements for successful transition of manufactured cells into therapy applications. The cell source (see the “Next-Generation” box) and culture conditions must be considered along with culture strategies and operation parameters for controlling cell proliferation and fate. When generating particular cell types for specific applications, it is critical to precisely control stem cell fate, usually by directing cell differentiation to a desi

red lineage. Major technical challenges in doing so include increasing expansion capacity, honing differentiation efficiency, enhancing population purity, and improving cell functionality. So it is imperative that a bioreactor system is precisely suited for expansion of specific cell types to optimize yield, purity, and quality of a desired cell product. In establishing platform technologies for cell manufacturing, customization of off-the-shelf solutions is common for accommodating growth characteristics that are unique to each cell type.

As in all cell culture expansion, the bioreactor type for stem cell expansion largely depends on whether the cells are growing as single cells in suspension, in monolayers, or in cell aggregates. Large cell densities combined with large cell amounts can be achieved in membrane reactors, stirred reactors, rotary reactors, fixed-bed reactors, and fluidized-bed reactors partially operating with microcarriers. However, too high a cell density could result in loss of cell properties for some stem cell types. In this case, the expansion procedure is aimed at low cell densities and frequent passage.

The key to stem cell differentiation is the microenvironment mainly due to the bioreactor, the differentiation medium (with growth factors), and the culture mode. The ideal differentiation system is scalable and fully controlled. Pluripotent stem cells are differentiated by culturing them as adherent monolayers at high densities or by growing them as embryoid bodies (EBs) in suitable systems such as stirred tanks or rotating bioreactors.

Traditionally, the culture of stem cells is performed on flat, two-dimensional (2D) surfaces (well plates and tissue-culture flasks) for their simplicity, low cost, and easy handling. A range of medium-scale, multitray options are available for adherent cells: Nunc CellFactory systems and Corning CellStack culture chambers, HyperStack vessels, and CellCube modules. More advanced designs for larger-scale traditional 2D culture of adherent stem cells include the multitiered Xpansion system from ATMI.

For nonadherent cells grown in suspension culture (or adhesion cells grown on microcarriers), traditional shake flask or spinner flasks such as the SuperSpinner D 1000 brand (from Sartorius-Stedim) are a standard choice. Shear forces generated by shaking or stirring mechanisms have been problematic for fragile cell types such as stem and progenitor cells. In addition, scale-up requirements through multiple, parallel manual processes make flasks unattractive because of the high labor cost and potential variability of output. More efficient, robust, and scalable configurations are highly desirable for generating cells for clinical, industrial applications. Stem cell bioprocessing most likely will require more sophisticated devices that facilitate mass and gas transport and environment monitoring and control at high cell densities. Moreover, automation and reproducible platforms will be imperative for consistent production of cell-based products.

Dynamic Bioreactors for Stem Cell CultivationBioreactors are closed systems in which a biological process can be carried out under controlled environmental conditions. A typical system comprises a bioreactor, sensors and actuators, and a controller and software to monitor and control the conditions inside the vessel. Design rules for mechanical, electrical, and bioprocess engineering are described in the CGMP and good automated manufacturing practice (GAMP) guidelines, as well as bioprocess equipment (BPE) guidelines of the American Society of Mechanical Engineers (ASME) for the design of bioprocess equipment.

Next-Generation FormulationsEach individual disease, condition, or disorder presents its own specific treatment considerations. So formulation of an efficacious cell product (especially the cell type and product format) must be designed appropriately for each respective therapeutic intervention. For example, readily available immune cell types that can be obtained easily from blood by routine apheresis procedures are routinely expanded and transfused or transplanted into patients who suffer from cancer, immunodeficiencies, and blood conditions. For nearly half a century, hematopoietic stem cells obtained from healthy bone marrow or cord blood have been collected, stored, and transfused to replace damaged or destroyed bone marrow from radiation and chemotherapy. In the past decade, other stem cell types (particularly pluripotent human stem cells with their unique potential for indefinite proliferation and capacity for multilineage differentiation) have been recognized for many applications in cell replacement therapies, tissue engineering, regenerative medicine, and immunotherapies.

At present, it is unclear whether the most efficacious therapy for a given disease or condition will be undifferentiated stem cells, lineage-committed progenitors, partially differentiated intermediates, or tissue-specific mature cell types that are terminally differentiated. Each cell type may require unique manufacturing design solutions, especially the more mature cells that can require three-dimensional (3D) architectures that mimic tissues or even whole organs. Specific bioreactor designs and bioprocess controls may be needed for expansion of proliferating cells and other culture specifications for differentiation of stem cells into a mature cell phenotype.

For the latter, synthetic scaffolds and biomatrices from decellularized tissues and organs have encouraging potential. Formulations that combine cells and other biomaterials using biofabrication techniques such as 3D bioprinting, stereolithography, and laser sintering will be important to consider for organ and tissue transplant products. However, large numbers of cells (most generated from stem cells at an industrial scale) will probably be used as feed stocks for such tissue-engineering applications. Those important biofabrication technologies are beyond the scope of this review.

Cell Sources: Many industrial-scale cell manufacturing approaches capitalize on the robust expansion capacity of proliferative cell types such as stem and progenitor cells. Platform technologies focus on implementing scalable and affordable culture systems for producing pure populations of undifferentiated cells without compromising their stem-cell characteristics. Classes of stem cells include embryonic and adult stem cells as well as induced pluripotent stem cells (iPSCs), each presenting its own benefits, limitations, and challenges in bioprocess development. All share an ability to proliferate indefinitely (unlimited self-renewal capacity) and vary in their differentiation potential.

Distinct bioengineering processes are needed to address cell culture conditions required for nonadherent cells that can grow in suspension (with or without agitation) and adherent cells that either grow as aggregates or need a biocompatible surface or substrate for attachment. Most cells derived from vertebrates (except for hematopoietic cell lines and a few others) are anchorage dependent and must be cultured on a suitable substrate that is specifically treated to allow their adhesion and spreading. Many such cell types can be adapted for suspension culture, however, which is advantageous for harvesting large-scale cultures from bioreactors.

Human embryonic stem cells (hESCs) isolated from the inner cell mass of blastocysts are pluripotent cells (4). They can differentiate into all cell types that compose an adult body, such as cardiomyocytes, neurons, pancreatic islets, hepatocytes, and chondrocytes (5,6,7,8,9). However, it is difficult to control the fate of stem cells, and hESCs elicit ethical debates by requiring manipulation of human embryos. For clinical applications, such cells present limitations related with immune rejection and the possibility of teratoma formation.

Adult stem cells (ASCs) p

resent no immunogenic complications on implantation because they can be isolated directly from a patient. These come from specific niches in different organs (e.g., bone marrow, peripheral blood, pancreas, lung, brain, and liver) where they contribute to regeneration and repair (10). Depending on their source, ASCs can be isolated with relative ease. However, they also face major limitations, such as difficulty in obtaining pure populations, limited expansion capacity, and restricted differentiation potential. These multipotent cells are often committed to their original cell lineage.

One of the most promising achievements in the stem cell field was reversion of somatic cells (e.g., fibroblasts and keratinocytes) to a state of pluripotency using defined reprogramming strategies (11,12,13). Induced pluripotent stem cells (iPSCs) evoked an explosion of scientific curiosity and industrial interest mainly because they are similar to hESCs (11, 12) and thereby could potentially replace them for clinical applications. Also, iPSCs are patient-derived cells and could be used for personalized medicine through autologous transplantation, preventing immune rejection in cell therapy applications. The possibility of reprogramming somatic cells into less mature developmental stages that could be more directly applicable to therapeutic applications is being intensely explored (14,15,16,17).

An optimal and universal stem cell culture system does not yet exist; however, bioreactor development has brought technological advances in recent decades. Stirred culture vessels, cell culture bags, hollow-fiber cartridges, bubble-column or air-lift vessels, rotary cell culture (RCC) systems, and microfluidic devices are described in the following sections. Many options are available, including fluidized-bed, packed-bed, and bubble- or air-lift designs (18).

Stirred Culture Vessels: The classic stirred culture vessel — from spinner vessels to stirred-tank bioreactors — is still the most widely used design. Process scale-up from laboratory to production-sized systems is therefore based on this design. Cylindrical bioreactors use a top- or bottom-mounted rotating mixing system with either a marine impeller for axial mixing or a Rushton turbine for gas-bubble breaking and axial mixing. Baffles are sometimes installed to enhance mixing. Gas is typically introduced below the mixing impeller, and liquid is added through the top of the bioreactor. A broad range of stirred-tank bioreactors is commercially available: microscale units such as the 10-mL ambr system from TAP Biosystems to small-scale units such as the 500-mL Cell Optimizer system from Wheaton Scientific Products; bench-scale units such as the 5-L and 14-L CelliGen BLU bioreactor from New Brunswick Scientific; and production-scale units such as the 2,000-L FlexFactory XDR platform from Xcellerex. Presterilized, preassembled, and single-use units are available in all sizes and can be used for batch, fed-batch, and perfusion cultures.

Most production facilities and FDA-approved biopharmaceutical processes use stirred-tank bioreactors. The knowledge accumulated from such experiences has facilitated their transition to stem cell bioengineering. Stirred-culture vessels are scalable and hydrodynamically well characterized. They enable culture homogeneity and easy, noninvasive sampling for continuous culture monitoring.

Fully controlled stirred-tank bioreactors provide automated control of the culture environment (temperature, pH, and dissolved oxygen) mandatory for reproducible stem cell cultivation. These bioreactors are highly flexible and can operate in different modes (batch, fed-batch, and perfusion). They can be adapted to different type of bioprocesses (stem cell expansion and/or differentiation) and accommodated to different three-dimensional (3D) cell culture strategies (cell aggregates, microcarriers, encapsulated cells), presenting widespread potential for stem cell bioengineering (15, 19,20,21).

The main limitation of stirred culture vessels is the hydrodynamic stress promoted by stirring. Until TAP Biosystems introduced its ambr system, the minimal volume required for experiments was quite large, demanding higher starting cell numbers and increasing the costs associated with optimization studies. That compromised the use of stirred-tank bioreactors for high-throughput applications. As discussed below, combining stirred-tank technology with 3D culturing approaches has led to significant advances in stem cell bioprocessing by increasing expansion yields, enhancing differentiation efficiencies, and improving cell functionality.

Cell Culture Bags: About 15 years ago, the Wave bioreactor bag (now from GE Healthcare) introduced the concept of a single-use bioreactor. For larger-scale suspension culture of nonadherent stem cells, multiple bag-type bioreactors were developed over time: the BIOSTAT CultiBag from Sartorious-Stedim, AppliFlex from Applikon, CELL-tainer from CELLution Biotech, Optima and OrbiCell bags from MetBios, PadReactor and Nucleo bioreactor from ATMI, and the Tsunami bioreactor. These are all mechanically agitated to provide mixing and oxygen transfer either by an external device such as a special rocking or shaker platform or with internal paddles. Conveniently, all come as disposable, single-use, presterilized bioreactors. Although successfully used in multiple biomanufacturing applications, this platform is limited either nonadherent stem cells or those that grow as aggregates or on biocompatible microcarriers.

Hollow-Fiber Cartridges: Developed in 1972 by Richard Knazek, the hollow-fiber bioreactor is a high-density, continuous perfusion culture system. Hollow fibers are small tube-like filters sealed into a cartridge shell so that cell culture medium pumped through the end of the cartridge will flow through them while cells grow in the space outside or surrounding the fibers. Modeled after the mammalian circulatory system, they create a semipermeable barrier of defined molecular-weight cut-off between the compartment where cells grow and the flowing medium. Different-sized cartridges come from suppliers such as FiberCell Systems, CellMax, Zymax, BioVest, and AutovaxD.

An interesting new hollow-fiber design called the modular extracorporeal liver system (MELS) from Stem Cell Systems is based on pioneering work by Jorg Gerlach from the McGowan Institute for Regenerative Medicine at the University of Pittsburgh (22). This unique system uses an interwoven four-compartment capillary-membrane technology for 3D perfusion with decentralized mass exchange. This bioreactor has been successfully used to grow high-density cultures of human embryonic stem cells (hESCs), mesenchymal stem cells (MSCs), and liver stem cells. The latter were shown to differentiate into functional hepatocytes. Then the bioreactor was used clinically as a temporary extracorporeal liver-assist device to provide interim support for a patient with acute liver failure.

All hollow-fiber bioreactors provide a large surface area in a small volume. Cells grow on and around the fibers at densities of >1 × 108 cells/mL, similar to what is typically found in vivo. High-density cell cultures offer important cost-of-goods (CoG) benefits mostly related to significant reductions in required materials such as cell culture media, serum, growth factors, and other additives (e.g., transferrin). These bioreactors were initially designed for harvesting products secreted by cells (such as growth factors, monoclonal antibodies, and viruses); they were not designed to allow harvest of the cells themselves. So collecting cells from these units is less efficient t

han with other bioreactor systems, resulting in suboptimal yields. Scalability is also limited, so hollow-fiber bioreactors are mainly used at laboratory scales.

Bubble-Column and Air-Lift Bioreactors: Bubble-column reactors belong to a class of multiphase reactors including three main categories: trickle-bed reactors (with fixed or packed beds), fluidized-bed reactors, and bubble-column reactors. The latter are basically cylindrical vessels with gas distributors at their bottoms. The gas is sparged in bubble form into either a liquid phase or a liquid–solid suspension. That simple design makes it possible to control the degree of shear uniformly within a reactor (critical to cell growth). Flow in bubble-column reactors is better defined than that of stirred-tank reactors.

An air-lift bioreactor contains a draft tube that provides performance-improving internal circulation. In air-lift bioreactors, internal liquid circulation is achieved by sparging only part of the reactor with gas. The sparged section has a lower effective density than the bubble-free section, and the difference in hydrostatic pressure between the two sections induces the liquid to move upward. That creates a draft that significantly improves circulation and oxygen transfer while equalizing shear forces in the reactor. With no mechanical agitation, these bioreactors are low-shear vessels that permit high-efficiency mass transfer with excellent flow and mixing properties. However, they have a few disadvantages, including considerable back-mixing between gas and liquid phases, high pressure drops, and bubble coalescence.

Rotary Systems: RCC bioreactors such as the Cellon from Synthecon-EHSI were developed from NASA research. A rotating 3D chamber keeps cells suspended in near free-fall, simulating microgravity conditions. These low–shear-stress bioreactors provide a well-mixed environment for cell growth as well as efficient gas transfer through a silicon membrane. RCC systems have been used to expand aggregates of differentiated cells (EBs) formed by hESCs and for multiple adult stem cells (ASCs) using scaffolds (23,24,25).

The two main disadvantages of RCC involve limited control of aggregate size and nutrient/gas concentrations throughout the vessel. Necrotic centers can form, leading to cell death inside the aggregates. Concentration gradients resulting from mass transfer limitations can create uncontrolled microenvironments. In addition, the working volume of RCC bioreactors is still low, which limits their use at higher scales.

Microfluidic Culture Systems: Microfluidic devices (or microbioreactors) — such as the ONIX microfluidic perfusion system from CellASCIS, the HurelFlow platform from Hurel Corporation, and the IVFLAB-6 microfluidic cell culture system from Smart Biosystems — are efficient small-scale systems used mainly in optimization of culture conditions for cell growth and differentiation with precise microenvironment control (18, 26). Arrays of microbioreactors have been developed to study growth and differentiation of hESCs and ASCs in a 3D perfusion system (27,28,29,30,31,32). The microenvironment can be controlled by adjusting specific operating parameters (such as the perfusion rate), providing a high-throughput system for evaluating the effects of soluble factor concentration gradients on different cell processes. However, the main limitations of these systems are the high shear stresses associated with perfusion and the continuous removal of important molecules secreted by cells that could ultimately compromise their performance.

3D Cell Culture StrategiesHuman ESCs and ASCs are traditionally cultured in 2D systems. The hESCs in particular are usually propagated as colonies on a top of feeder layers of inactivated fibroblasts. The inherent variability, lack of control, and low cell production yields associated with these methodologies make them unattractive and unsuitable for clinical, industrial scale. So moving stem cell culture protocols from 2D cell monolayers to 3D cultures is fundamental to enhancing their performance and fully exploiting their potential.

A general recognition of the spatiotemporal cell environment’s importance for cell behavior has contributed to an acceptance that 3D provides a cellular context closer to what actually occurs in vivo. Mechanical and chemical properties (e.g., surface tension, gravity, cell adhesion, and movement) are key players in determining cell, tissue, and organ function. Cells integrate external signals, including those from cell–cell direct interactions as well as secretion and exchange of soluble factors and/or metabolites. Extracellular matrices (ECM) not only provide a physical support for cell growth and maintenance, but they are also critical for cell–cell communication within 3D microstructures, and that improves cell behavior, identity, and function (33,34,35).

Engineered 3D microstructures can thus provide for higher degrees of efficiency, robustness, and consistency and more predictive cultures. A number of microstructures have been established: self-aggregated spheroids (3D cell aggregates), microcarriers, and more complex scaffolds based on natural, nonanimal polymers such as gels and sponges (e.g., alginate and cellulose microfibers) or synthetic materials (36,37,38,39,40,41).

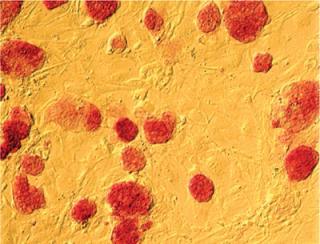

Culture of Stem Cells As Aggregates: Cultivation of ESCs as 3D aggregates is usually associated with differentiation. The most robust method for generating differentiated cells from ESCs is through formation of EBs, when ESCs cultured in suspension self-aggregate and spontaneously differentiate into multiple tissues (42). That differentiation has been shown to recapitulate aspects of early embryogenesis, including formation of complex 3D arrangements in which cell–cell and cell–matrix interactions are thought to support development of three germ layers and their derivatives (43, 44). The main limitation of such a system is, in fact, a lack of control in directing differentiation toward a specific lineage — leading to a mixture of different cell types. So companies need efficient, integrative downstream approaches to further purify their culture outcomes into desired cell-type populations.

The differentiation of human embryonic teratocarcinoma stem cells (NT2 cells, a model system of hESCs) into neurons can be improved when cells are cultivated as 3D aggregates in stirred bioreactors. In fact, the effect is striking in comparison with a 2D protocol: By integrating both expansion and differentiation steps in a controlled bioprocess, neuronal differentiation efficiency can be significantly increased (by >10-fold) while drastically reducing (by >30%) the time required for differentiation (31, 45). In the past few years, numerous developments in 3D aggregate systems have greatly improved controlled expansion of undifferentiated hESCs (46,47,48) and their directed differentiation into functional cell types, such as neurons (49) and cardiomyocytes (30).

Cultivation of ASCs as 3D aggregates also has been explored. The efficient expansion of human neural stem cells as neurospheres (50, 51) and neonatal porcine pancreatic cells as islet-like tissue (52) together represent a significant milestone toward cell therapy appl

ications by providing sufficient numbers of functional cells required to treat neurodegenerative diseases (e.g., Parkinson’s disease) and Type 1 diabetes.

Cultivation of Stem Cells in or on Microcarriers: A microcarrier is a support matrix for attachment and growth of anchorage-dependent cells in suspension systems. Microcarrier cultures are characterized by high surface:volume ratios that accommodate higher cell densities than those obtained with static cultures. The area available for cell growth can be adjusted easily by changing the number of microcarriers, further facilitating process scale-up. That helps reduce cell cultivation costs by lowering the amount of media, growth factor formulations, and expensive supplements required. For each stem cell type and bioprocess, it is important to optimize specific parameters: inoculum density and microcarrier type and concentration.

A broad range of microcarriers is commercially available. Supports can be porous or nonporous; composed of gelatin, glass, collagen, or cellulose; and presenting dimensions of 170–6,000 μm. They can be functionalized with different coating materials (e.g., ECM proteins and small molecules) to further improve cell-culture performance (attachment and growth). Microcarrier technology thus allows for flexibility in culturing cells with different conformations and on different matrixes.

Cells cultured in 3D while immobilized in macroporous beads (e.g., Cytopore 2 from GE Healthcare and Cultisphere S from Sartorius Stedim) are protected from shear stress, although diffusion of oxygen and nutrients can be limited within the beads. These systems have been used for expansion and differentiation of mouse ECSs (53, 54) and for propagation of MACs (55).

With nonporous microcarriers (e.g., GE Healthcare’s Cytodex 1 and 3), cells are attached on bead surfaces, assuming a configuration similar to that of 2D monolayers. These cells are equally exposed to the bulk medium, preventing diffusion gradients in culture. ASCs including mesenchymal and pancreatic stem cells demonstrated higher expansion yields on nonporous microcarriers while keeping their phenotype and differentiation potential (32, 56). One challenge that needs addressing is optimization of cell harvesting protocols after expansion and differentiation to guarantee efficient cell–bead separations and cell recovery yields without compromising viability, potential, and/or functionality.

Culture of hESCs on dextran- or cellulose-based microcarrier supports coated with matrigel or denatured collagen has exhibited improved cell growth characteristics while retaining differentiation potential (57,58,59,60,61). Seeding hESCs as single cells onto microcarriers prevented EB formation and subsequent uncontrolled differentiation. Furthermore, hESC–microcarrier aggregates formed in culture. Such 3D cell growth increased cell yields over those of 2D culture systems. The cells retained an ability to differentiate into the three germ layers (59, 61).

ATMI’s iCellis bioreactor is an interesting new fixed-bed, fully integrated design packed with custom macrocarriers that allow for very high-density cultures. The matrix comprises medical-grade polyester microfibers and provides ≤1,000 m2 growth surface area in a compact volume. With cells immobilized onto that biocompatible growth support, ATMI tells me that volumetric yields have been dramatically increased. Because biomass multiplication occurs in a fixed bed, this type of bioreactor can be inoculated at very low density. That reduces the number and volumes of seed trains considerably and dramatically lowers associated costs. A built-in magnetic-drive impeller evenly distributes culture media, ensuring low shear stresses and higher cell viabilities. The medium flows throughout the fixed-bed, from bottom to top. From the top, liquid falls as a thin film down the outer wall, where it takes up O2 to oxygenate cells. That unique waterfall-style oxygenation — together with a gentle agitation and biomass immobilization — enables compact iCELLis bioreactors to achieve and maintain high cell densities equaling the productivity of much larger stirred-tank units.

Cultivation of Encapsulated Stem Cells: Cell-encapsulating strategies offer the opportunity to customize and design a scaffold environment with specific biomaterials (e.g., alginate, polylactic-coglycolic acid, poly-l-lactic acid, and hyaluronic acid). This creates a microenvironment that can suit the self-renewal of stem cells or direct their differentiation along with promoting their organization into 3D configurations like native tissues. In this context, several hydrogels have been used with stirred bioreactors to enhance formation of 3D structures and stem cell differentiation to myocardium (62), hepatocytes (37, 38), pancreatic islets (40, 63), bone (64), cartilage (65), hematopoietic cells (66), neuronal cells (67), and vascular grafts (68). Encapsulating cells also may make it possible to circumvent harmful effects of shear stress.

Encapsulation technology should contribute to the success of transplantation tests. Encapsulated tissue constructs are less susceptible than cells in suspension to immunorejection. Their delivery is better targeted, and their in vivo degradation kinetics can be tuned for more efficient and functional integration into host organs (39, 67).

Bioprocess ParametersIn terms of expansion and differentiation, successful stem cell bioprocessing depends on controlling key process variables: nutrient and metabolite concentrations, growth factor compositions, and physiological parameters (e.g., temperature, pH, and oxygen). The concentrations of nutrients and metabolites should be strictly monitored and controlled during cultivation because they affect cell growth, viability, and differentiation. Stem cell culture outcomes depend on the presence and concentration of growth factors that provide survival, proliferation, and differentiation signals to the cells.

To enhance stem cell metabolism and further improve culture performance, different operation modes can be adopted, including fed-batch and perfusion. A fed-batch strategy is often considered most suitable for tuning and optimizing cell metabolism. When nutrients are rationally provided, their uptake and consumption are energetically more efficient, which reduces metabolite accumulation in culture supernatant (31, 69). And growth factors play a crucial role in regulation of stem cell behavior. So perfusion mode has been preferentially adopted for most stem cell bioprocesses because it ensures continuous renewal of nutrients and other factors as well as continuous removal of metabolic by-products (31, 62). The interactions among growth factors and other process parameters are not fully understood. It is therefore critical to quantify and clarify these effects and interactions to design a culture process for optimal production of a specific cell-type population.

Finally, propagation and differentiation of stem cell cultures depend on physiochemical conditions such as temperature, pH, and dissolved oxygen (pO2). But few studies have been conducted on the effects of temperature and pH in stem cell culture. MSC differentiation is enhanced at lower temperatures (32 °C) than in 37 °C conditions (70), whereas high temperatures (39

6;C) enhanced megakaryopoiesis in CD34-enriched cord blood cells (71). High pH (7.60) enhanced differentiation and maturation of megakaryocyte progenitors (72), whereas lower values (7.1) increased their expansion capacity (73).

Oxygen is critical to hESC culture (18), and emerging evidence suggests that reducing its concentration to low levels (74, 75) can be beneficial for in vitro maintenance of pluripotent hESCs, supporting their self-renewal and reducing spontaneous differentiation while maintaining karyotypic integrity (76, 77) compared with normoxia conditions (20%). So a robust strategy has been developed for mass production of undifferentiated hESCs using pO2-controlled bioreactors (61). In that work, a 12-fold improvement in expansion yield was observed over standard 2D protocols when pO2 was controlled at low levels.

Process variations in culture environments clearly can be strategically applied to direct and manipulate stem cell behavior in vitro. For optimized process yields, control system performance is critical to managing and documenting perfusion, recirculation, and feeding of bioreactor cultures for an optimal growth environment and maximized cell viability. This is particularly important for the dynamic environments created by differentiating stem cells.

One of the most flexible and reliable tools available for that purpose is SciLog’s automated MabTec system. Three modular units are engineered to fit seamlessly with any bioreactor type in any configuration for enhanced performance. First, a recirculation provides homogeneous low-shear circulation and timed flow reversal to prevent cell aggregation and eliminate pockets of inconsistent media. Second, a feed module interactively maintains long-term balance between removed media and new feed solution by accurately controlling mass flow rates based on gravimetric measurements of perfused and fed media. And third, the perfusion module allows programmable sequencing of either changes in perfusion rate or media collection to interactively maintain balance between removed media and new feed solutions. Ramp-up, ramp-down, and exponential changes can be made depending on cell growth cycle or metabolic requirements. The adaptable open architecture of this system integrates with any bioreactor to accommodate the demands of complex stem cell cultures for optimizing cell processing at an industrial scale.

Moving from Art to Science By DesignMany technological problems remain to be solved. Culturing stem cells still relies on both science and art, and optimal and robust cultivation strategies and culture conditions for manipulating their fate have yet to be determined. Defining engineering principles and practices for control, automation, standardization, validation, reproducibility, and safety of process and product will be critical for therapeutic and industrial applications.

Numerous bioreactor designs cultivate and differentiate stem cells, but few commercial products have reached the market. Several joint industry–academic research programs are focusing on development of stem cell bioreactors. No optimal, universal stem cell bioprocess yet exists that can embrace all applications. Nonetheless, knowledge gained during recent years, with quantitative characterization of expansion and differentiation processes, provides important insights for implementing potentially universal production platforms.

Over the next few years, significant developments in this field should include innovative culture systems that integrate sophisticated monitoring platforms to ensure continuous culture evaluations at a cellular level. Such advances will fundamentally contribute to implementing novel cell therapies and ultimately address clinical demands.

Author Details

John E. Hambor, PhD, is a consultant and director of stem cell–based drug discovery at The Cell Therapy Group; 1-203-623-9923;

REFERENCES

onic Stem Cell Culture. Cells Tiss. Org. 192:39-49.

red Vascular Graft Combining a Biodegradable Scaffold, Muscle-Derived Stem Cells and a Rotational Vacuum Seeding Technique. Biomaterials 29:825-833.