The successful commercialization of a biopharmaceutical product begins with a robust and productive cell line. Inefficient cell-line development (CLD) can lead to costly delays and roadblocks. For that reason, small, new, and virtual companies — and even established and mid-size companies — often seek the support of outsourcing partners to develop their cell lines.

Outsourcing CLD activities can ease many pressures associated with manufacturing new biotherapeutics. The benefits of outsourcing CLD and associated processes include access to specialized expertise and technology:

Access to Specialized Expertise and Technology: Service partners should provide a high-performing, reliable cell line in a timely manner.

Cost Savings Associated with Building and Maintaining Facilities: The cost of goods is reduced by preventing the need to spend capital to develop a productive cell line in-house.

Decreased Time-to-Clinic/Time-to-Market: The use of established platforms supports rapid development and scale-up, limiting the time needed to optimize your production pipeline.

Reduced Risk: Outsourcing partners should have internal testing services to guarantee regulatory compliance, increasing the chances of product approval.

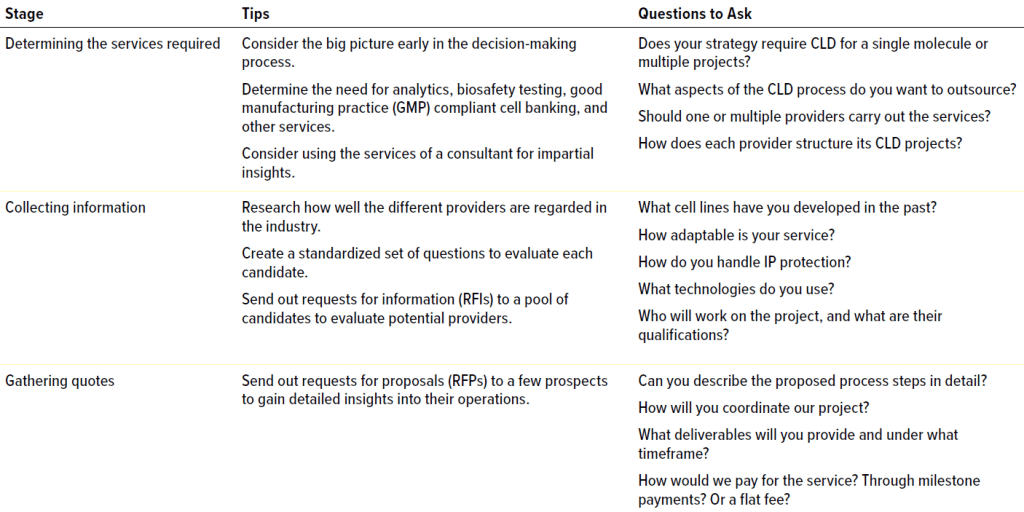

Selecting a suitable and reliable partner is key to reaping the benefits of outsourcing CLD (see the “Ensuring the Best Start” box). Selecting the right outsourcing partner to work with from the many available choices is not always straightforward. Herein, we provide a framework to streamline the selection process and maximize the chance of a successful CLD partnership (Table 1). We subsequently highlight critical features of Sartorius work packages that support successful CLD projects.

Table 1: To choose the right cell-line development (CLD) service provider, streamline your selection process with this simplified framework.

Essential Considerations for Selecting a Service Partner

Drug developers must be aware of multiple factors before choosing a CLD partner.

Expertise and Performance: First, selecting a provider with a high level of expertise and substantial experience is crucial to a project’s success. Credible CLD providers typically have an established track record of successful projects completed on time and within budget.

Additionally, specialist CLD partners should be using powerful technologies; a high-performing platform is key to delivering high product yields, product quality, and scalability, all of which are required for a commercially attractive production cell line.

The platform also must be compatible with the target molecules, which are becoming increasingly complex and diverse. Robust platforms can be used successfully with a broad range of product types (for example, fusion proteins, bispecific antibodies, fragments, and nonantibody products), and a provider should have a track record demonstrating such capabilities. An additional benefit is experience with advanced bioprocessing approaches, such as seed-train intensification, dynamic perfusion culture, and continuous manufacturing.

The production of complex modalities like bi- and tri-specific antibodies requires well-developed cell lines and harmonized expression cassettes. Robust cassettes will contain potent genetic elements to ensure robust and stable transcription and translation, and efficient secretion. Reliable host cell lines are characterized by high secretion and assembly capabilities.

Established screening strategies maximize the chance of selecting a reliable and high-performing clone early in a development process. An efficient screening workflow requires representative scaled-down systems (for example, the Ambr15 bioreactor) and data analysis capabilities to test the performance of different clones, including the critical quality attributes (CQAs) of the produced biologic. This is particularly important in the manufacture of biosimilars, which have strictly defined quality profiles that must be met for regulatory approval.

Selecting the right cell line for the production of a complex product demands significant expertise, equipment, and analytical tools. The right partner will implement established protocols to understand key process parameters and how they affect the CQAs of the product, allowing that partner to deliver robust cell lines to support your project.

| Ensuring the Best Start The process of creating a new cell line, good manufacturing practice (GMP) banking, and quality testing is expensive. Cell-line development (CLD) costs approximately €500,000, and the subsequent creation of a master cell bank (MCB), working cell bank (WCB), and analytical testing can cost up to €1 million. The CLD timeline also is a critical consideration.From the provision of the DNA sequence, the path to reach the first GMP batch takes one to two years, depending on project complexity. Choosing the service partner with the right experience and technology will ensure that your CLD project has the best possible start, minimizing risky delays and additional expenses. |

Flexibility and Control: An ideal partner will provide open lines of communication and give service users a high level of control over the process. Flexibility also is a desirable feature of a service partner. Some companies may want to hand over their processes to their providers; others may want to be more involved, make decisions at critical milestones, and be able to stop projects whenever they want. Such decisions can be determined when the two parties discuss how their project will be coordinated and managed.

Related to flexibility and control over a project is the importance of easy process transfer. Does a service provider offer full support for transferring a process to your manufacturing site? Is the process robust and streamlined enough to facilitate a simple transfer? Does the provider offer a platform process that meets your project pipeline?

Risk Reduction: In additional to adaptability, a critical feature of good service providers is their ability to mitigate the risk of project failure. That includes having adequate quality systems and documentation in place to ensure regulatory compliance. Such records should include host–cell-line history reports, certification of consumables and reagents (animal-origin free), deviation and change control, full traceability of all CLD activities, proof of monoclonality, and instrument qualifications. Additionally, an outsourcing partner should be able to demonstrate freedom to operate for all processes applied to CLD.

Also requiring careful negotiations between a sponsor and service provider are the contractual financial commitments and obligations, particularly when preliminary results are less than satisfactory. At Sartorius, we alleviate such concerns by offering CLD services as work packages. Services can be stopped at any time, and a client pays only for the work performed. This allows companies to test the service and gain confidence in our partnership and capabilities before making costly commitments. Another alternative is to trial several service providers on different projects simultaneously to find the best fit. However, that requires significant funding and expanded resources for handling concurrent projects.

A further complication that could increase risk lies in managing multiple partners. Depending on their needs, sponsors may have to secure the services of diverse vendors providing analytics, testing, and cell-banking services. Managing multiple providers can create complex communication pathways and lead to delays.

At Sartorius, we streamline the development process by offering a truly one-stop-shop service that limits the logistical complexities and risks of using multiple providers. Our focus on quality from the beginning, proven reliability, versatile technology, and expert guidance throughout helps you navigate the entire process with confidence.

A Comprehensive Service: When selecting an outsourcing partner, a drug developer must consider the spectrum of capabilities that each candidate provides. Beyond core CLD competencies, an ideal outsourced partner should provide holistic support toward securing regulatory approvals. Such support services could include media- and process-optimization consultation, data-analytics software and consultation, product characterization, cell-banking, biosafety, and quality testing.

As well as contributing to risk mitigation, such an integrated offering from a partner simplifies project management throughout a CLD process. At Sartorius, we offer our customers the flexibility to select our Chinese hamster ovary (CHO) platform service package or self-select the workflow steps they want to outsource. In addition, each of our customers is assigned a dedicated client manager to coordinate the project and ensure that strong lines of communication are established and maintained throughout. A single point of contact is extremely valuable when dealing with a complex project with many components and stakeholders.

Business Model: For small and early phase drug developers, a clear understanding of cost models and pricing is necessary to manage and balance the costs in their financial plans. Some service providers charge a flat fee; others operate using royalty-based models or charge milestone or success fees.

The decision about which model works best will depend on how the business operates. Some businesses might prefer a lower upfront cost but will incur significant additional fees. However, it is typically most cost-effective to pay a higher service fee and prevent extra expenses later in a commercialization process. This will be particularly important for companies planning to scale up production and take their drugs to market. Another consideration is how licensing works for the new cell line — what is covered under the license, and is it possible to sublicense? The absence of future fees also makes biotechnology companies more attractive to potential prospective investors, who will seek to find the greatest return on their contribution.

Timeline: For an early drug developer, the race to be the first to clear regulatory approvals can have a significant impact on funding and a company’s future. As a result, the pressure to meet timelines and expedite CLD is immense. However, the candidate claiming the shortest CLD time does not always win the race. When evaluating an outsourcing partner, it is necessary to look beyond advertised timelines and investigate each company’s current backlog, capacity use, reported delays, and wait times for potential partners.

Selecting a provider with the capacity to start CLD quickly can be important if times to clinic and market are key drivers. Sartorius has a large CLD capacity with flexible staff. Our fully developed platform approach was designed with a high level of automation and scalability at the forefront, allowing us to accelerate drug-development timelines. Typically, our projects start within two weeks of signing a contract and deliver a fully characterized research cell bank in 14 weeks.

Photo 3: Setting up a master cell bank (MCB) by placing cell stocks in liquid nitrogen for long-term storage

Selecting a Compatible Service Partner

Many drug developers have limited CLD capabilities and require reliable providers to help perform critical early process steps. However, with so many potential service providers across the globe, selecting the right partner to establish a robust cell line can pose a significant challenge. We have outlined some critical considerations for choosing a compatible service partner and some key steps you should be taking to ensure that you get informed insights (Table 1).

A suitable partner will have a proven track record of delivering robust and highly productive cell lines. It will adapt to your project needs and have effective risk-mitigation strategies in place. An ideal outsourcing partner will provide you with a broad range of services to help streamline project management, including reliable characterization and testing services to help you navigate global regulations.

Sartorius is experienced in handling CLD partnerships, having successfully created more than 120 cell lines. As well as supporting CLD projects, our experts have designed the products and solutions used at each step in the journey. Our service model requires very little commitment from our partners at initial stages, significantly reducing uncertainties. Finally, our fast lead times and an upfront pricing model give our partners a clear idea of costs and timelines at the outset. These features form the basis of our reliable and respected CLD service offering.

Jennifer Lawson and Monika Panakova are product managers for cell line, media, and testing solutions. Katy McLaughlin is a scientific content writer, and Christoph Zehe is a research fellow for advanced cell biology at Sartorius.

Contact: BPSTradeMedia@Sartorius.com.