Figure 1: Filtration principle of dynamic body-feed filtration (DBF) with diatomaceous earth (DE) (left) and conventional filtration (right)

In the past decade, biopharmaceutical manufacturers have demonstrated major improvements in monoclonal antibody (MAb) production, exhibiting product titers frequently in the range of 5–10 g/L using standard fed-batch mammalian cell cultures (1, 2). Increased product yields allow for smaller-scale production vessels. With 2,000-L single-use bioreactors already commercially available, single-use manufacturing of biomolecules becomes more and more an option. Other recent developments in the biopharmaceutical industry — e.g., drugs for smaller indications and more potent drugs allowing for lower dosages — will further stimulate the demand for smaller and more flexible single-use manufacturing facilities.

Although single-use technology in general has matured considerably over the past few years, some unit operations (e.g., cell removal) still need more attention to become more economical and robust. High product titers often result from increased cell densities rather than increased specific productivities per cell, and the resulting solids content poses considerable challenges on commonly applied harvesting technologies. Currently the most prevalent single-use harvesting technology, depth filters block at lower loading capacities with higher biomass concentrations. Higher contaminant concentrations also make depth filters more sensitive to batch variation, which can lead to 50% oversizing of filter area to compensate for fluctuating filtration capacities. That drives up costs and increases waste. Other new commercially available single-use cell-removal technologies such as centrifuges still lack capacity. For harvesting higher–cell-density cultures, a major technical breakthrough would be welcomed.

Body Feed Filtration Successful for Plasma Fractionation

When we looked at other industries that have similar process needs — such as the plasma fractionation industry — we found that they often use body-feed filtration for clarification of solutions with high solids content. The first use of diatomaceous earth (DE) as a filter aid in fractionation of human plasma was reported over five decades ago (3). Since then, a number of manufacturing processes for production of intravenous immunoglobulin (IVIG), albumin, and clotting factors have been developed based on that technology (4–6). Fractionation uses the principles of selective precipitation by pH adjustment, ionic strength, addition of alcohol, and temperature shifts. Precipitates are removed by depth filtration often in combination with diatomaceous earth, which is added as an aid to increase filter throughputs.

Recently, the principles of body-feed filtration have been tested for harvesting cell cultures, with promising results (7). Our objective was to evaluate the technology as a potential single-use alternative to centrifuges and depth filters. Here we describe the most interesting findings we obtained using a number of cell lines and culture media, which were kindly provided by different biotech companies. Together with Rentschler Biotechnologie GmbH, Sartorius Stedim Biotech tested the optimized conditions in a 600-L cell culture production process to evaluate the scalability of body-feed filtration technology.

How Body Feed Filtration Works

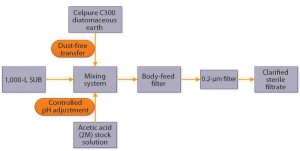

When the concentration of solids or colloids is too high in turbid biological process fluids needing clarification, the filter cake forming on the surface of a filter becomes impermeable and blocks the filter (Figure 1, right). Adding highly porous DE creates a more permeable filter cake, which prevents blockage (Figure 1, left).

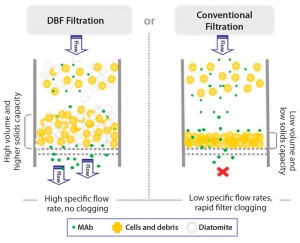

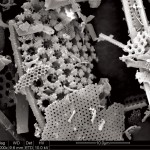

Figure 2: Mean particle-size distribution of cell-free Chinese hamster ovary (CHO) culture

supernatants from three different harvest days determined at different pH values; green curve = pH 7.0, red curve = pH 5.0; measurement performed using a Mastersizer 2000 system (Malvern Instruments)

The minimum amount of DE to guarantee smooth filtration depends on the particle concentration. Laboratory-scale experiments with many different mammalian cell lines, culture media, and viabilities revealed a correlation between the wet cell weight (WCW) and the required amount of DE at constant pH (data not shown). For all tested cultures, the optimum DE concentration was in the range of 40–50% of WCW. In all cases, the filter-aid ratio could be reduced significantly to a range of 20–30% when pH was lowered to pH 5.

Low pH Precipitation Improves Clarification Results

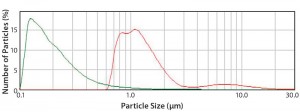

Photo 1: Scanning electron microscopy (SEM)

shows the porous structure of Celpure 300 diatomaceous earth (magnitude 1,000 times).

Performance differences between acidified (pH 4.3–5.5) and neutral cell culture fluids for other cell-removal technologies such as microfiltration (4) and depth filtration (5) can be explained by precipitation of smaller particles at lower pH levels. The solubility of cell debris and negatively charged impurities such as DNA and host-cell proteins (6) decrease along with pH. Figure 2 shows the mean particle-size distribution for three different cell-free cell culture supernatants at neutral pH (green line) and after the pH of those cultures was lowered to pH 5 (red line). Lowering the pH leads to formation of bigger particles and makes the typical submicron particles (<1 μm) present at pH 7.0 completely disappear. Therefore, body-feed filtration would clearly benefit from lowered pH.

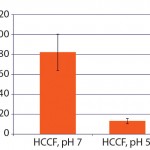

Figure 3: Turbidity measurement of the DBF filtrates at pH 7.0 and pH 5.0 for 10 different

cell cultivations with an initial turbidity of

2,396–3,235 NTU

In addition to the significantly reduced filter-aid concentration, all tested acidified cell culture supernatants showed much clearer filtrates than their neutral counterparts (Figure 3). When we analyzed the particle-size distribution of neutral body-feed filtrates, we detected only small particles (<0.4 μm). Filtration with a 0.2-μm membrane barely reduced those turbidity values, indicating that very small particles are mainly responsible for the higher turbidity values of the neutral body-feed filtrations.

The absence of smaller particles in acidified culture supernatants probably is also the reason for higher filtration capacities at constant filter-aid concentrations. We assume that small particles deposit in the pores of DE particles, lowering the permeability and filtration capacity of the DE overall. By increasing the filter-aid concentration, we could increase its capacity for retaining small particles without losing the required cake permeability.

Significant reduction of filter-aid consumption at low pH is promising from both economical and handling points of view. Another important economical factor to consider is the recovery rate at lower pH levels. Although most antibodies are stable at acidic conditions (9), in some cases low-pH precipitation of cell culture fluid will lower recovery rates, most likely due to coprecipitation of the antibody (6). However, some authors have described that lowering the pH value influenced overall antibody recovery positively by preventing enzymatic reduction of the product (10, 11). In all our laboratory-scale body-feed tests at low pH, we achieved a recovery rate >85% (data not shown).

Positive Impact on Residual DNA and Host-Cell Protein Load

Figure 4: Mean residual DNA amount after DE filtration at pH 5.0 for 10 different cell culture supernatants, expressed in percentage of initial

DNA concentration at pH 7.0, measured in the cell free supernatant; initial concentrations

were 475–730 ppm (DNA quantitation with PicoGreen assay from Life Technologies).

With the low-pH precipitation and subsequent retention of contaminants by body-feed filtration, we accomplished a significant reduction of DNA in the primary recovery step from our cell culture runs. Figure 4 shows the mean residual DNA content of 10 different body-feed filtrates after low-pH precipitation at pH 5.0. We first measured the initial DNA content in the neutral, cell-free supernatant of each cell culture at pH 7.0. After a low-pH precipitation step followed by DE filtration, DNA content in the cell culture supernatants was reduced by 65%.

Pilot-Scale Test Results

At Rentschler Biotechnologie, we performed tests at pilot production scale to evaluate the applicability of DBF technology for manufacturing purposes (12). In total, 1,000 L of a high–cell-density (17.6 × 106 cells/mL, 95% viability) Chinese hamster ovary (CHO) cell fed-batch culture were available for the depth-filtration and body-feed filtration runs. In the largest single run, we subjected 600 L to body-feed filtration at pH 5.0. WCW on that day was 8%.

For the scale-up experiment, we installed seven process-scale modules with a total filtration area of 1.61 m2 in a universal stainless steel holder. The filter cassettes consist of two polyethylene filter plates, which retain the DE and biomass (Figure 6).

Figure 6: (top) 3-D illustration of commercial

DBF process-scale module holder; (center) a drawing of one single-use DBF module; (bottom) flow path inside one module indicates in red the feed flow and in green the filtrate flow path; dotted lines indicate the filter plates.

In total, we added 12 kg of Cellpure C300 DE to the 600-L bulk harvest. Prefilled DE bags were connected with a dust-free adapter to a mixing bag for fast and safe DE transfer. Just five minutes of gentle mixing was sufficient to dissolve that DE powder in the cell suspension. Before filtration, we adjusted the pH of the resulting mixture to a final level of 5.0 and gently mixed it for two hours at 140 rpm.

Pressure increased steadily during filtration (Figure 7, left). We terminated filtration when the pressure reached 1.3 bar and the crude harvest had been filtered. During the entire filtration process, the system maintained a high and stable flux slightly above 300 L/m2/h. Overall, a capacity of 311 L/m2 was achieved. We monitored a very low turbidity of 5–8 NTU (Figure 7, left) in the clarified harvest stream during filtration.

After neutralization, pool 3 (the final pool) exhibited a turbidity of 41 NTU (Figure 7, right), which was considerably higher than turbidity had been during filtration. Inadequate dosing of the neutralization buffer probably had resulted in local pH excursions and caused the turbidity increase in that final pool. In a small-scale parallel test, the turbidity increase was prevented through more gentle neutralization of the filtrate pool. To improve that neutralization step, an integrated ready-to-use process skid is under development that will enable controlled inline pH adjustment and prevent overshooting.

We found IgG1 recovery to be acceptably high at 85% (Figure 7, right). In the future, an optimized neutralization procedure and larger postfiltration flush should further improve MAb recovery. We monitored contaminants such as a host-cell protein and DNA throughout the process. In the final pool (after buffer flush and neutralization), those levels were reduced from 841 to 629 mg/mL and 13.8 to 5.0 μg/mL, respectively.

Figure 7: Results of DE body-feed scale-up experiment at reduced pH (5.0) with seven filter modules; filtration performance (left), pressure (bar), and flux (L/m2) as well as the course of turbidity during filtration; recovery of IgG1, blue columns (right) measured from crude harvest and harvest pool without buffer flush (pool 1), with buffer flush (pool 2), and after neutralization of harvest fluid (pool 3)

Concluding Remarks

Our aim was to demonstrate the universal applicability of a new single-use harvest method for mammalian cell culture, suitable even for high–cell-density cultures. Tests using crude harvests from different cell lines and culture conditions allowed us to determine the optimal concentration of DE as a filter aid in relation to WCW, which is an easily accessible process specific for cell removal and harvest processing. With respect to process economics, the 50% reduction of filter aid required with low-pH filtrations is promising.

Generally, the pilot-scale results confirmed our findings from DBF filtration trials at laboratory scale: Reducing pH to 5.0 after addition of DE to crude cell-culture supernatant gives the best performance in terms of filtration capacity, flux, and contaminant removal.

The applicable flux rate of DBF technology is very advantageous. A 600-L harvest was processed within only an hour of filtration using just seven modules. A module holder allows arrangement of a maximum 33 modules, so we estimate that a harvest volume of ~3,000 L could be filtered in the same time.

In conclusion, this method allows effective clarification of high–cell-density, crude cell culture harvests in a single-use set up at large scale. Economically and competitively, it can replace centrifugation, which is currently the method of choice for large-scale cell removal. Even very dense crude cell harvests could be clarified quickly at high flow rates. Moreover, this method has the additional benefit of efficiently reducing contaminants in a single step. Scalability — one of the most important requirements in bioprocessing — is easily attainable following a generally linear approach with very consistent process performance.

References

1 Kelley B. Industrialization of MAb Production Technology: The Bioprocessing Industry at a Crossroads. MAbs 1(5) 2009: 443–452.

2 Buttler M. Animal Cell Cultures: Recent Achievements and Perspectives in the Production of Biopharmaceuticals. Appl. Microbiol. Biotechnol. 2005, 283–291.

3 Cohn EJ, et al. Preparation and Properties of Serum and Plasmaproteins, IV: A System for Separation into Fractions of the Protein and Lipoprotein Components of Biological Tissue and Fluids. J. Am. Chem. Soc. 68, 1946: 459–475.

4 Curling J, et al. Production of Plasma Proteins for Therapeutic Use. Wiley-Blackwell: Hoboken, NJ, 2012.

5 More J, et al. Purification of Albumin from Plasma. Blood Separation and Plasma Fractionation. Harris J, Ed. Wiley-Liss: Hoboken, NJ, 1991.

6 Stucki M, and al. Investigations of Prion and Virus Safety of a New Liquid IVIG Product. Biologicals 36, 2008: 239–247.

7 Westoby M, et al. Effects of Solution Environment on Mammalian Cell Fermentation Broth Properties. Biotechnol. Bioeng. 108(1) 2011: 50.

8 Delavaille D. How to Apply Old Techniques to New Processes. European Downstream Technology Forum, 7–8 September 2010, Göttingen Germany. Sartorius Stedim Biotech AG: Goettingen, Germany.

9 Singh N, et al. Clarification of Recombinant Proteins from High Cell Density Mammalian Cell Culture Systems Using New Improved Depth Filters. Biotechnol. Bioeng. 110(7) 2013: 1964.

10 Brodsky Y, et al. Caprylic Acid Precipitation Method for Impurity Reduction: An Alternative to Conventional Chromatography for Monoclonal Antibody Purification. Biotechnol. Bioeng. 109(10) 2012: 2589.

11 Kao Y, et al. Mechanism of Antibody Reduction in Cell Culture Production Processes. Biotechnol. Bioeng. 107(4) 2010: 622.

12 Trexler-Schmidt M, et al. Identification and Prevention of Antibody Disulfide Bond Reduction During Cell Culture Manufacturing. Biotechnol. Bioeng. 106(3) 2010: 452.

13 Minow B, et al. High-Cell-Density Clarification By Single-Use Diatomaceous Earth Filtration. BioProcess Int. 12(4) 2014: S36 –S47. c

Tjebbe van der Meer, MSc, is a product manager at Sartorius Stedim Biotech GmbH, August-Spindler-Straße 11, 37079, Göttingen, Germany, tjebbe.vandermeer@sartorius-stedim.com. Benjamin Minow, PhD, is director of cell culture disposable manufacturing at Rentschler Biotechnologie GmbH, Erwin Rentschler Straße 21, 88471 Laupheim, Germany, benjamin.minow@rentschler.de. Bertille Lagrange, MSc, is a scientist at Sartorius Stedim Biotech GmbH, August-Spindler-Straße 11, 37079, Göttingen, Germany, bertille.lagrange@sartorius-stedim.com. Franziska Krumbein, Dipl. Ing (FH), is director of process technologies at Sartorius Stedim Biotech GmbH, August- Spindler-Straße 11, 37079, Göttingen, Germany, franziska.krumbein@sartorius-stedim.com. And Francois Rolin, Dipl. Ing, is with ChangeXplorer Production SAS, Z.I. des Waillons 02220, Braine, France changexplorer@orange.fr.