Clarifying cell culture broth is the first downstream unit operation in an elaborate sequence of steps required to purify a biological therapeutic. A combination of centrifugation, depth filtration, or tangential-flow filtration (TFF) is used for that operation. The availability of large-scale, single-use, depth filtration technology in the recent years, however, has given process developers the capability to improve and simplify downstream processes.

Podcasts

New Technology for Broad Screening of Cell Microbial Contaminants, Including Viruses

Two case studies are presented highlighting the impact PLEX-ID System can have to rapidly identify virus contaminants resulting in better control of biologics manufacturing process, with the potential to characterize various sources of excursion through genotyping information.

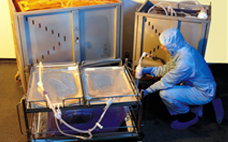

Implementation of a 2000L Single-Use Bioreactor and Clarification System at an Existing cGMP Facility

This case study highlights a seven month project to upgrade a 100L stainless steel facility to a 2000L single-use facility without affecting current clinical manufacturing while adhering to cGMP requirements.

Manufacturing Roundtable: Building Biomanufacturing Expertise in Emerging Markets

The mainstream adoption and success of mobile, single-use manufacturing platforms, combined with the introduction of off-site training programs provide companies with the ability to quickly set up and operate fully functioning biomanufacturing facilities globally.

cGMP Operational Excellence and Infrastructure Harmonization from Lab to Plant

This presentation outlines the key issues facing the R&D and Quality cGMP environments and presents key IT-based solutions that have been implemented by leading pharma and biotech companies.

BioSimilars and Biomanufacturing Briefing

Speakers: Karin Lucas Director, Training & Education BioTech Primer, Inc Timothy Fawcett Scientific Director BioTechnical Institute of Maryland, Inc. Listen to the audio cast here

Economic Impact of Single-Use Bioreactors

In order to match the improved titers and yield Innovation has provided, many biopharmaceutical companies are re-evaluating the operational costs of stainless steel and exploring the economics of single-use systems.

BioSimilars Have Arrived: Perspectives on the Path Forward

While the Biosimilar market is expected to reach $20B by 2020, four factors will play a major influence on just how quickly the biosimilar market will grow: patent expirations, regulatory pathways, development challenges and viability of a commercial model.

ROUNDTABLE β Single-Use Technologies: Industrialization, Standardization, Regulation β Common Goals and Differing Expectations

As the adoption and maturation of single-use technologies continues to evolve, many end-users are looking for single-use suppliers to standardize products, materials, and equipment in order to improve efficiency and lower costs. An expert group of industry suppliers discusses the pros/cons and differing expectation surrounding this trend.

Using the XS Toolbox to Optimize Strain Design and Development for Efficient Microbial GMP Production

No single strain or vector is capable of being the best expression option for all types of biopharmaceuticals. The XS Systemβ’ ultimately decreases the time of strain screening and design to enable the fast creation of a valuable production strain and efficient cGMP process.