An old engineering adage says that in any technical project, you can get speed and/or quality and/or cost-efficiency — but you never get to have all three. The idea is that emphasizing any one of those parameters necessarily deemphasizes one or both of the others. For most of the biopharmaceutical industry’s early years, companies operated on that assumption. Many organizations saw speed as the weakest link that could be more or less ignored; others had money to burn. The smartest…

June 2020 Featured Report

The Upstream Perspective: Taking Efficiency Beyond Cell-Line Development

With 20 years of experience in the biopharmaceutical industry — at Genentech, Applied Biosystems, Cell Genesys, Cellerant Therapeutics, and Bayer — Yuval Shimoni has written frequently for BioProcess International on a number of production topics. Those have ranged from process improvements and bioreactor scale-down validation, to raw materials management, to addressing variability and virus contamination events. For this featured report, we discussed hardware and instrumentation, quality by design (QbD) and related approaches, and other strategies that can take expediting upstream…

The Downstream Perspective: Putting Product Knowledge to Work Using Technological Innovations

After over a quarter century in the industry — including downstream processing (DSP) and manufacturing directorships at Boehringer Ingelheim and leadership roles in technology development, quality, and manufacturing at Novasep — European consultant Margit Holzer is a recognized expert in downstream processing of biopharmaceutical products. Holding a doctorate in biotechnology from the University of Natural Resources and Applied Life Sciences in Austria, Holzer is familiar to BPI readers as both an author and conference participant (1, 2). And in May…

The Analytical Perspective: Turning Data Into Information Requires Teamwork

As head of bioanalytics at Sanofi, Claire Davies leads a team of >90 people involved in development, qualification, and transfer of methods to internal and external commercial quality control units; characterization, comparability, and developability of proteins and gene therapies; and analytical support for up- and downstream development, production, product release, and stability testing. She has served in a number of roles over 18 years with Sanofi, from chemistry, manufacturing, and controls (CMC) leadership of preclinical to commercial products (leading and…

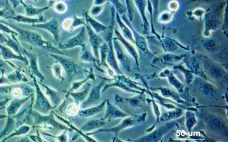

Get to IND Faster: Accelerated and High-Performance Cell-Line Development

In April 2020, Samsung Biologics hosted a webinar with John Gill, the company’s director of cell-line development (CLD). He focused first on chemistry, manufacturing, and controls (CMC) activities needed for preparing an investigational new drug (IND) application. Then he introduced a fast timeline for managing CLD programs to accelerate client projects to success. CMC Activities Samsung Biologics is a fully integrated contract development and manufacturing organization (CDMO). Starting with a client’s gene of interest (GoI), Gill’s group tailors CLD to…