Adoption of single-use manufacturing continues to expand globally and is showing no signs of slowing down. And why should it? The biopharmaceutical industry is challenged to produce safe, effective therapies and vaccines amid the constant pressure to lower cost per dose in addressing healthcare needs of not only the western hemisphere, but emerging markets as well. To meet these challenges, manufacturers are turning to single-use and hybrid systems that incorporate a balance of stainless and single-use equipment. Over the past…

March 2016 Supplement

A Single-Use Process for Production of Recombinant Human Follicle-Stimulating Hormone

Follicle-stimulating hormone (FSH) is a heterodimeric glycoprotein consisting of noncovalently linked α and β subunits. It stimulates the growth of immature follicles in ovaries and primary spermatocytes in testes and thus plays an important role in human reproduction (1). Human menopausal gonadotropin for infertility treatment was first introduced into clinical practice in 1950 (2, 3). Subsequently, treatments with urinary FSH have been replaced by recombinant human FSH (rh-FSH), which has been shown to provide several advantages such as absence of…

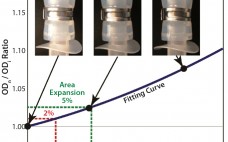

Pressure Rating for Bioprocess Single-Use Assemblies

Single-use systems (SUSs) are engineered process equipment solutions for pharmaceutical and biologics production. They offer several key advantages, such as lowering energy costs to reduce utility requirements, minimizing cleaning validation efforts, reducing water and chemical use, and enabling flexibility in manufacturing. Use of SUSs is increasingly popular in almost all fields of bioprocess applications (1, 2). SUSs most commonly comprise components made of polymeric materials, which together create a system or unit operation designed for one-time or campaign use. Single-use…

How Advanced Single-Use Polymeric Materials Influence Extractables Testing

Implementation of single-use systems in both upstream and downstream applications continues to grow rapidly. Parallel to that growth is the concern about purity levels of polymeric single-use systems because compounds found in disposable materials of construction can leach into process fluids or final drug products. By definition, extractables studies are intended to identify chemical substances that could migrate into process fluids. These tests generally take place under exaggerated conditions that exceed those typically found in bioprocess manufacturing or storage. Industry…

Monitoring Live Biomass in Disposable Bioreactors

Often simply referred to as capacitance, radio-frequency (RF) impedance has been used for over two decades to measure online biomass. It is generally regarded as the most robust and reliable method to monitor live-cell concentrations in mammalian cell culture (1). Many biopharmaceutical companies have now made the transition from conventional glass or stainless steel multiuse (MU) vessels to single-use (SU) bioreactors. Disposables are rapidly becoming the preferred platform for new processes requiring current good manufacturing practice (CGMP) compliance. At the…

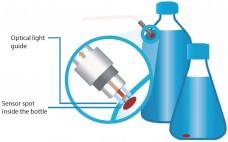

Using Optical Sensors for Bioprocess Monitoring: A Measurement Technique for Bioprocessors

Over the past decade, the application of chemical optical sensors for bioprocess monitoring has gradually taken roots. Constant further development of this measurement technology and the possibility to manufacture such sensors in various designs (even for single-use applications) have led to new state-of-the-art devices for the biotechnology sector. Chemical optical sensors enable in situ, real-time monitoring of important culture parameters without sampling and therefore without disturbing a culture. Implementing this technology can decrease workloads and deepen knowledge about bioprocesses. In…

Evaluating New Film for Single-Use Bags: Growth Performance Studies with Animal and Human Cells

In biopharmaceutical development and manufacturing processes, single-use technology has become widely accepted (1). Storage and cultivation bags are particularly common. They are fabricated from plastics consisting of multilayer films and are typically provided gamma-sterilized by suppliers (2). The bags offer several advantages such as savings in time and cost. Lowered contamination risk results from reduced cleaning and sterilization demands. However, some adverse effects of polymer films on cell growth and metabolism have been reported, both for storage and cultivation bags…