Increasingly efficient bioreactors allow biopharmaceutical manufacturers to achieve higher cell densities. That improved upstream efficiency has led to new purification challenges resulting from high product and contaminant concentrations as well as complex components. Therefore, harvest and clarification techniques are evolving to incorporate feed pretreatment, flocculation, and different filtration technologies such as normal-flow, tangential-flow, and depth filtration. The objective is to increase process capacities and filtrate quality, ultimately reducing biomanufacturing costs. New strategies for clarification of recombinant proteins (in particular, monoclonal…

2014

Immunoglobulin Fc-Fusion Proteins Part 1: Their Design and Manufacture

Over the past three decades, 45 monoclonal antibody (MAbs) and MAb-derivative products have been approved for therapeutic use in the United States (Table 1). One class of antibody derivatives is growing in importance: Fc-fusion proteins. Many biologically active proteins, including receptor ECDs (see “Abbreviations” box), cytokines, enzymes, and bioactive peptides have very short serum half lives because rapid renal clearance limits their exposure in target tissue (and, consequently, their pharmacological effect). The primary reason for fusing a biologically active protein…

Replacing Reverse-Phase Chromatography for Mass Spectrometry: Is Salt-Free Size-Exclusion Chromatography Ready?

Protein mass is often determined using ultraperformance liquid chromatography (UPLC) coupled with electrospray-ionization mass spectrometry (UPLC/ ESI MS or simply LC-MS). A UPLC system equipped with an ultraviolet (UV) detector serves as an assisting vehicle to deliver purified and separated protein molecules to the mass analyzer. Reserved-phase chromatography (RPC) is the most common chemistry chosen to serve this purpose. For sample purification, not only does RP-UPLC use salt-free mobile phases that are amenable to MS, but it also can efficiently…

Cost Estimation for Protein A Chromatography: An In Silico Approach to MAb Purification Strategy

Monoclonal antibody (MAb) production has adopted an accepted technology platform for downstream processing (1). The need for more economic processes has been addressed by increasing MAb titers in fermentation and aiming toward greater bioreactor volumes to increase productivity. Consequently, cost pressures are now passed on to downstream process groups. Membrane and chromatography resin savings are more important for MAb processes than ever before, with highly productive cell cultures generating large volumes of process fluid to purify (2). Traditionally, protein A…

Preuse, Poststerilization Filter Integrity Testing for Single-Use and Stainless-Steel Installations

According to current European Union good manufacturing practice (EU GMP), integrity testing of sterilizing-grade product filters should be performed preuse poststerilization (PUPSIT) and immediately after use. In addition, PDA’s Technical Report 26 states that preuse integrity tests are preferably performed after filter sterilization. Performing an integrity test of an already sterilized product filter in-line requires wetting the filter while maintaining the downstream side sterile. The test gas must also be evacuted on the downstream side throughout testing maintaining sterility. The…

Banking Cord Blood for Stem Cell Research

Cord blood is becoming an increasingly popular and important topic of discussion among expectant parents. It comes from a newborn’s umbilical cord and contains hematopoietic stem cells (HSCs), which are the building blocks of a body’s blood and immune system. After a baby is born, cord blood is routinely discarded as medical waste — unless the parents choose to have what blood remains in the umbilical cord collected. Presently, more than 90% of cord blood is discarded, limiting the potential…

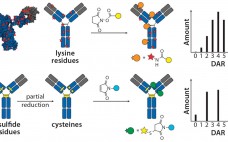

Antibody Drug Conjugates: The State of the Art

Monoclonal antibodies have dominated the biopharmaceutical market for over two decades. Few people doubt that their future success in fields such as oncology, inflammation, and autoimmune diseases owes much to the development of antibodies conjugated to cytotoxic drugs. Like all great innovations, this is a breathtakingly simple concept: Combine the targeting specificity of an antibody with a small-molecule drug as an effector component joined to that antibody by means of a small chemical or peptide linker, and you have a…

Bioprocessing Challenges of Antibody–Drug Conjugates

Development of highly potent active pharmaceutical ingredients (HPAPIs) is clearly a pharmaceutical industry trend. Highly potent drug products involve active agents and APIs that are so potent therapeutically (or simply just outright toxic) even in small dose that special precautions are required during their manufacture — particularly when handling the active agents. Such requirements include maximal containment and isolation of the process stream. Worker exposure and environmental release clearly pose problems. The necessity and intensity of containment efforts with HPAPIs…

The Next Step in Homogenous Bioconjugate Development: Optimizing Payload Placement and Conjugate Composition

[Audio Recording] Bringing a new biologic drug to market is a long and expensive process, with research and development (R&D) cycles that can span up to 15 years and may cost over a billion dollars. Biologic drug development also involves significantly more complex manufacturing and CMC components than does development of small molecules. Nonetheless, the pharmaceutical industry is increasingly shifting its R&D efforts to focus on biologic drugs. According to a recent report from Tufts Center for Study of Drug…

Bioconjugation Reaction Engineering and Kinetics Simulation

Bioconjugates represent an important and growing class of pharmaceuticals that include PEGylated proteins, vaccines, and antibody-drug conjugates (ADCs) (1–8). Numerous protein conjugation techniques exist (9). Among the more important conjugation chemistries used for protein therapeutics are N-hydroxysuccinimide (NHS), aldehyde, and maleimide (10–13). To date, process development of industrial biopharmaceutical conjugation reactions has largely been empirical in nature. Typically, many experiments testing different reaction parameters are required to identify optimal process conditions. In some instances, nonmechanistic statistical models can be used,…