Most recombinant monoclonal antibodies (MAbs) are produced by mammalian cells. Because biopharmaceuticals derived from mammalian tissue culture carry the risk of adventitious virus contamination, regulatory agencies expect risk-mitigation strategies to include validation of purification unit operations for their ability to clear viruses (1). Guidelines from the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH) describe how to prove viral clearance in downstream purification processes using an orthogonal approach (2). Viral log10 reduction values (LRVs) are…

Author Archives: Stefan R. Schmidt

Controlling Glycosylation in Fusion Protein Manufacturing to Generate Potent Biobetters

The pipelines of pharmaceutical companies are full of biological drugs. Many of them are innovative therapeutic proteins, but a growing number represent biosimilars and biobetters (Figure 1) (1). Biobetters typically are defined as being “based on innovative biologics but with improved properties” (2). Their development benefits from known therapeutic approaches and mechanisms of action resulting in low risk, fast paths to the clinic and thus lower costs. Superiority is achieved through extended half-life (t1/2), improved efficacy, and reduced immunogenicity or…

Drivers, Opportunities, and Limits of Continuous Processing

Biologics represent a significant group of approved drugs, and they are expected to continue their exceptional growth in the foreseeable future. At first glance, innovative monoclonal antibodies (MAbs) and their derivatives seem to dominate the field; however, biobetters, biosimilars, and other therapeutic proteins have gained in relevance lately. This diverse portfolio also is reflected in the range of different biomanufacturing processes used. Most blockbuster antibodies are produced by mammalian cells cultured in large bioreactors (10–20 mÂł) in fed-batch mode. But…

Single-Use Depth Filters: Application in Clarifying Industrial Cell Cultures

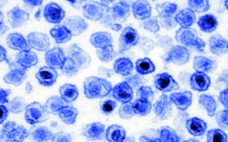

For current process development phases, many biomanufacturers’ attention is directed increasingly to the first unit operation in downstream processing, which is the removal of cells and cell debris from culture broth and clarification of supernatant containing a biopharmaceutical product. Given the high cell densities achievable with both mammalian and microbial cell culture processes, primary recovery can be a significant challenge. The current trend in cell culture is to increase product titers with enriched culture media, improved cell productivity, and increased…

The Single-Use or Stainless Steel Decision Process: A CDMO Perspective

Decisions regarding whether and when to use single-use (SU) (disposable) devices or stainless steel (SS) equipment for biopharmaceutical manufacturing have been discussed for more than a decade. To date, no argument in terms of safety, cost-effectiveness, or operational efficiency is fully convincing to choose one technology platform or the other for all applications. Biopharmaceutical companies often do not have in-use data to make strategic manufacturing decisions. But one group has been significantly growing its expertise in use of single-use technologies:…