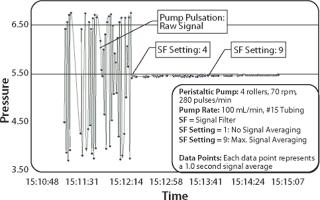

Single-use purification processes typically use peristaltic pumps to provide single-use fluid pathways. However, peristaltic pumps are known for generating severe pressure oscillations. These oscillations have an effect on the accurate measurement of the process, thus limiting the effective monitoring and controlling of system pressure.

SciLog is pleased to announce a significant performance breakthrough in pressure monitoring: achievement of a 98% reduction in signal noise level associated with peristaltic pump pulsation. In this solution, a significant increase in the signal to noise ratio is achieved while a fast sensor response is maintained. This important breakthrough enables automation applications and accurate data collection in single-use purification platforms.

SciLog manufactures pressure sensors for single-use purification applications in the bioprocess industry including tangential flow filtration (TFF), normal flow filtration (NFF), and preparative chromatography. SciLog pressure sensors (SciPres) are used in laboratories, pilot plants, and GMP production facilities the world over. These sensors are available in five different tube sizes: Luer, 3/8” Barb, ½” Barb, ¾” TC, and 1.0” TC and are part of a single-use pressure-sensing loop consisting of a sensor, cable, and transmitter.

All SciLog sensors are precalibrated and NIST traceable by sensor ID, and the sensor bodies are made of medical grade polysulfone meeting USP Class VI specifications. All sensors are gamma-stable and have been performance tested with 1.0 normal sodium hydroxide (100 hour exposure test) solution as well as with 70% isopropyl alcohol (see www.SciLog.com).

Figure 1 shows the pressure sensor output (psi) with increasing digital signal processing. The sensor monitor display, as well as the 4-20 mA monitor analog output has significantly improved signal-to-noise ratio within the operating ranges of commercially available peristaltic pumps.