Millipore Corporation’s new ChromaSorb membrane adsorber uses an innovative membrane-based anion exchanger to perform robust impurity clearance at a wide range of salt concentrations. This feature enables users to improve their process economics by eliminating the downstream bottleneck of buffer tank capacity inherent with the use of other membrane adsorbers, as well as traditional resin chromatography.

ChromaSorb membrane adsorber provides enhanced process flexibility and efficiency and a smaller manufacturing footprint than traditional anion resins and columns, eliminating the need to dilute feedstreams prior to processing. The ChromaSorb solution comprises a linearly scalable family of single-use devices, which bind negative impurities, including host cell protein (HCP), DNA, endotoxins, and viruses at salt concentrations well above those of traditional resins and membranes.

The ChromaSorb 0.08-mL device is the smallest chromatographic scaling device available, designed to minimize the use of feedstock during scaling studies. The 0.08-mL device requires a third less feed-stock volume than other membrane adsorbers, thus allowing for the design of robust experiments. It is currently available for process development and validation studies. The ChromaSorb 0.08-mL device linearly scales up to the process size ChromaSorb 50-mL and 500-mL devices, which will be available soon.

Greater Capacity at Higher Salt Concentrations

Today’s higher-titer feed streams result in larger intermediate product pools. Traditional anion-exchange resins or membrane adsorbers require greater buffer volumes to dilute the pool to the conductivity range needed to remove impurities. This increases capital equipment costs and production floor requirements, driving up operation costs.

ChromaSorb membrane adsorber consists of a novel anion membrane that exhibits a higher binding strength for negatively charged impurities than traditional quaternary (Q) amine based anion exchangers.

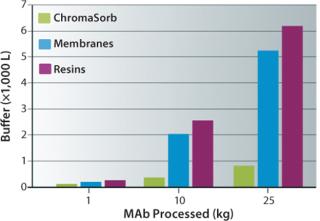

This innovative technology allows the ChromaSorb membrane adsorber to bind impurities at higher salt concentrations than traditional resins or competitive membrane adsorbers. Figure 2 demonstrates that the ChromaSorb membrane adsorber radically reduces buffer usage compared with other anion polishing technologies, which in turn minimizes product processing times and alleviates buffer tank bottlenecks.

Impurity Removal

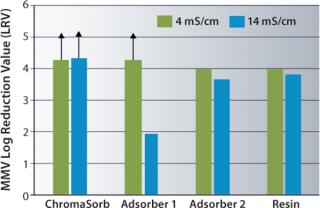

Rigorous testing shows that the ChromaSorb membrane adsorber demonstrates robust binding of negatively charged impurities including viruses, HCPs, endotoxins, and DNA — and consistently retains these impurities over a wide range of salt conditions. Figure 3 shows the results of tests Millipore conducted to compare clearance of mouse minute virus (MMV) by ChromaSorb membrane adsorber with that of other commercially available anion-polishing technologies.

Researchers spiked two feed stocks of different conductivities with MMV to target titers. They processed the feedstocks through the ChromaSorb 0.08-mL device, two other commercially available membrane adsorber devices, and one commercially available anion exchange chromatography resin. Virus assays were conducted on the samples.

ChromaSorb membrane adsorber showed no virus breakthrough at either conductivity, resulting in LRV ≥4.3. Membrane adsorber 1 showed no virus break-through at the lower conductivity, but break-through was observed at the higher conductivity, resulting in virus removal to less than two logs. Membrane adsorber 2 and the chromatography resin showed low-level virus break-through at both feed conductivities in three of the four devices tested.

The tests concluded that ChromaSorb membrane adsorber was the only technology that consistently removed all viruses at both low and high salt concentrations, thus illustrating its versatility at the polishing step.

Unparalleled Process Economics

The ChromaSorb membrane adsorber significantly improves process economics. It consistently and reliably removes impurities from MAb and protein processes without the expenses associated with typical resin chromatography, including column hardware investment, lengthy clean-in-place (CIP), extensive validation, and packing expertise. The drawback of currently available membrane adsorbers is their inability to perform at higher salt conditions, so they require significant dilution. With the ChromaSorb membrane adsorber, you can consistently and reliably bind impurities in MAbs and proteins without having to worry about such bottlenecks.