Researchers traditionally have produced lentivirus (LV) in adherent cultures by transient transfection using media containing animal serum. The method is inexpensive for process development (PD) and early clinical trials, but it requires increased operator manipulations and costs during scale-up. Development scientist Adam McLeod delivered an Ask the Expert webinar on 27 August 2019 to illustrate how GE Healthcare Life Sciences at the Centre for Advanced Therapeutic Cell Technologies (CATCT) in Toronto, Canada, approaches lentiviral vector (LVV) manufacturing. McLeod explained that…

Wednesday, October 23, 2019 Daily Archives

Production of Transient Lentiviral Vectors in HEK 293T Cells: Cultivation on Fibra-Cel Disks in a Single-Use, Packed-Bed, Stirred-Tank Bioreactor

Although demand for lentiviral vectors (LVs) for cell and gene therapy is increasing, the standard two-dimensional culture systems used to produce LVs present significant disadvantages. Current bottlenecks in LV production are caused mainly by such disadvantages. Switching to use of bioreactors can eliminate those problems because bioreactors offer the benefits of process automation, tight regulation of production conditions, and reduced labor input. The study reported herein was carried out by the group of David Parsons at the University of Adelaide.…

Single-Use Tubing Systems: Confidence Through Validation

Single-use systems (SUSs) are becoming increasingly common in bioprocessing operations because of their low capital requirements and validation costs. As this trend continues to develop, pharmaceutical manufacturers are asking SUS manufacturers to provide assurance that their products comply with current good manufacturing practices (CGMPs) and do not alter drug products by exceeding established operating ranges. Certification of product cleanliness has become common for manufacturers of final packaging components such as vials and stoppers, but rarely are tubing products certified to…

Ask the Expert: Automated, Closed-Loop, Inline Monitoring of CAR T Cells in a Production Process

Jan Van Hauwermeiren (vice president of sales and marketing at Ovizio Imaging Systems) joined BPI for an Ask the Expert webinar on 29 August 2019. He demonstrated how his company’s iLine F microscopy system combines sensitive optical capability with machine learning to monitor chimeric antigen receptor (CAR) T-cell expansion, transduction, and activation. The device captures holographic images of cells as they pass through a single-use conduit running between a microscope and bioreactor. Cells then funnel back into culture without additional…

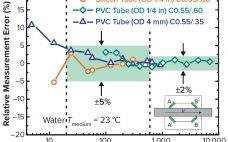

Flow Monitoring in Continuous Processing and Single-Use Systems

Flow sensors placed at critical points in both upstream and downstream processes fulfill the regulatory goals of the process analytical technology (PAT) framework. PAT has been defined as a mechanism for design, analysis, and control of biotechnical and pharmaceutical manufacturing processes through measurement of critical process parameters (CPP). Constant flow monitoring can support its overall targets fundamentally to reduce production cycling time prevent rejection of batches enable real-time release increase automation and control improve energy and material use facilitate continuous…

Cell and Gene Therapy Leadership: Building Successful Teams

Cell and gene therapy (CGT) companies are opening the door to a paradigm shift in medicine. They’re rapidly developing some of the most exciting new therapeutics we’ve seen in decades, delivering meaningful results for patients and changing lives for the better. In the latest RSA Talent Equity report (1), we focus on the CGT sector, looking at the profile of leadership teams that bring the most value to shareholders in this exciting area. Growing Pressure in CGT CGT companies face…

WuXi selects Irish site for first vaccine plant

Chinese CDMO WuXi Biologics has laid plans to build a manufacturing facility in County Louth, Ireland, months after forming a vaccine joint venture. In May, WuXi Biologics formed a joint venture with Shanghai-based Hile Bio-Technology to service a 20-year manufacturing contract with an undisclosed vaccine developer estimated to be worth more than $3 billion (€2.7 billion). At the time, the Chinese contract development and manufacturing organization (CDMO) said it was scouting for a dedicated vaccine manufacturing site, and it turns…