Millipore Corporation’s new Viresolve Pro and Pro+ solutions are a major leap forward in virus clearance technology. As biotech manufacturers experience high titers, the evolution of process platforms and increasing focus on cost of goods, the demand for a robust high-capacity unit operation is increasing. Viresolve Pro and Pro+ solutions deliver robust parvovirus clearance, high productivity, and performance assurance.

The Viresolve Pro and Pro+ solutions offer the highest level of virus clearance for the development of biopharmaceutical products. The patent pending membranes, newly designed device formats, new highly sensitive performance tests, and comprehensive range of services and virus clearance expertise offer high throughput and virus clearance assurance. For challenging feedstreams, the Viresolve Pro+ solution includes an adsorptive polishing step that protects against variability in solution conditions. All device formats are fully disposable and caustic stable for optional in situ sanitization.

Robust Parvovirus ClearanceViresolve Pro and Pro+ devices offer high log reduction value (LRV) performance and are designed and validated to deliver ≥4-log clearance of minute virus of mice (MMV) (18–24 nm) and ≥5-log clearance of x-murine leukemia virus (80–110 nm). Millipore conducts unique performance tests built into every level of production, including testing of the membrane, device lot release, and 100% device testing.

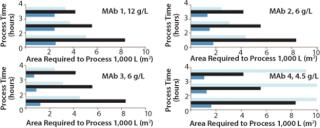

Viresolve Pro and Pro+ membranes allow for processing the high-concentration feed streams that are becoming more common with recent improvements in bioreactor productivity and advancements in other downstream processing technologies. Millipore targeted 5–10 kg/m2 mass capacity for monoclonal antibodies (MAbs) in the 5–10 g/L concentration range. In addition to high mass capacity, the Viresolve Pro and Pro+ solutions were designed to deliver mass flux in the 1,250–2,500 g/m2/h range, enabling ≤4-hour processing times.