Bioprocess monitoring and automatic feeding of key nutrients such as glucose and amino acids are critical to obtain optimal high productivity in cell culture systems. Here we present a complete, closed-loop system that integrates a Groton Biosystems Automated Reactor Sample System with a nutrient analyzer and a reactor control system that demonstrates a powerful, automated online, real-time feeding system.

Materials and MethodsA Groton Biosystems Automated Reactor Sampler (ARS-M) is connected to a four-vessel DasGip Parallel Bioreactor System (PBS, Jülich, Germany) controlled by the DasGip Control 4.0 OPC Edition Software (DCS) and a YSI7100 Biochemistry Analyzer (YSI, Yellow Springs, Ohio). Data and control were transmitted between the individual units of the Integrated System by OPC protocol.

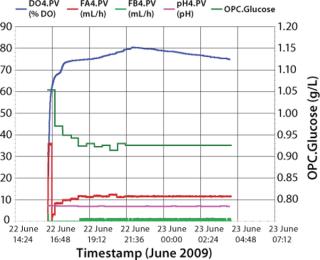

Glucose was chosen as the feedstock. The ARS-M delivered on a programmed schedule an aliquot of reactor media to the nutrient monitor. The glucose concentration data point was transmitted to the ARS-M, which transformed the data point in OPC format. The reactor control system OPC client polled automatically and repetitively the ARS OPC server to acquire new data as available. The reactor control system then operated on the data to calculate a new feedstock flow rate to satisfy the selected set-point value. Figure 1 shows a schematic of the system set-up (photographed upper right).

In this demonstration, the system was programmed to acquire samples from four reactors with a single reactor sample and analysis cycle performed in 10 minutes. The set point was selected as 2 gm/L glucose. The reactor control system feedback algorithm was configured to achieve and maintain a steady state glucose set point (2 g/L) as shown in the figure.