Recently, purification of biomolecules, such as peptides and proteins, by process scale HPLC using reversed phase silica gel media has become increasingly important in biopharmaceutical production. DAISOGEL SP-300-C4-BIO is the newest product using this technology, a butylsilyl(C4)-modified silica gel with 30-nm pore diameter for applications involving peptides, proteins, and other large molecules. Besides selectivity, several other aspects influence the performance of chromatography in preparative processes and consequently have a crucial effect on the total process cost. Therefore, when we developed this product, we focused on properties such as loadability, recovery, mechanical stability, and chemical robustness.

Loadability has been believed to depend on the physical surface area of a packing material, which is typically measured by N2 adsorption (BET method). Consequently, smaller pores (e.g., larger surface area) should lead to increased loadability. However, this principle is misleading in the case of large solute molecules, because they cannot penetrate smaller pores, so the chromatographically accessible surface area has to be considered: 30-nm pores allow large molecules complete access to the interior surface.

In an experiment (data not shown), phases with three different pore sizes were packed into columns, and their maximum BSA-loadabilities were calculated from measurements of break through curves. The 30-nm phase showed higher loadability than those with 12-nm and 20-nm pore size, respectively.

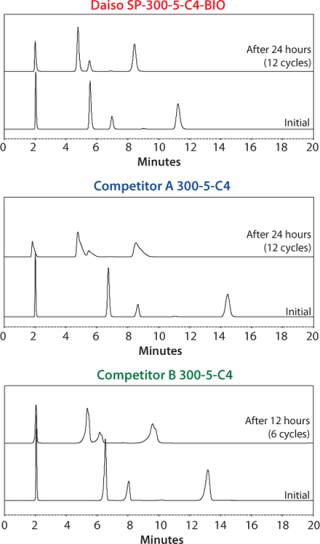

Another problem frequently observed in the case of peptide and protein chromatography is poor recovery caused by hydrophobic surface properties. Sometimes irreversible adsorption or aggregation occurs on hydrophobic Octadecyl Silane (ODS) phases. On the one hand, C4 is a less hydrophobic substituent and prevents such irreversible adsorptions or aggregations considerably. On the other hand, this substituent is less durable than ODS against extremely acidic conditions. We have successfully overcome such durability problems, making use of our new proprietary modification technology. A specially designed C4 ligand modification combined with a perfect endcapping minimizes the presence of residual silanol groups and protects the silica surface. Figure 1 compares chromatographic performance after alkaline treatment. SP-300-C4-BIO shows less peak asymmetry than comparable media.

Finally, high mechanical stability is particularly important when packing columns with dynamic axial compression. Our SP-300-C4-BIO series media shows no obvious alteration of back pressure or particle size after 10 consecutive packing cycles and is therefore suitable for preparative and process scale chromatography. SP-300-C4-BIO series is available with 10-, 15-, and 20-micron particle sizes for process HPLC.