Speed to market is an important consideration for the development of lifesaving therapies, including recombinant monoclonal antibodies. However, increased speed must be balanced with quality to enable quick and efficient delivery of biopharmaceuticals to patients. Important determinants of quality include the genomic location and integrity of the transgene sequence within a recombinant cell line. Traditional methods of genetic characterization can provide incomplete information and results can be difficult to interpret. However, next-generation sequencing (NGS) approaches such as Targeted Locus Amplification…

Upstream Processing

The Upstream Perspective: Taking Efficiency Beyond Cell-Line Development

With 20 years of experience in the biopharmaceutical industry — at Genentech, Applied Biosystems, Cell Genesys, Cellerant Therapeutics, and Bayer — Yuval Shimoni has written frequently for BioProcess International on a number of production topics. Those have ranged from process improvements and bioreactor scale-down validation, to raw materials management, to addressing variability and virus contamination events. For this featured report, we discussed hardware and instrumentation, quality by design (QbD) and related approaches, and other strategies that can take expediting upstream…

Get to IND Faster: Accelerated and High-Performance Cell-Line Development

In April 2020, Samsung Biologics hosted a webinar with John Gill, the company’s director of cell-line development (CLD). He focused first on chemistry, manufacturing, and controls (CMC) activities needed for preparing an investigational new drug (IND) application. Then he introduced a fast timeline for managing CLD programs to accelerate client projects to success. CMC Activities Samsung Biologics is a fully integrated contract development and manufacturing organization (CDMO). Starting with a client’s gene of interest (GoI), Gill’s group tailors CLD to…

Anticipating Cell-Line Challenges to Drive CMC Readiness

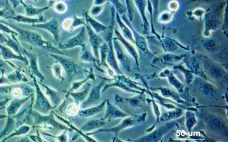

Development of a safe and high-quality Chinese hamster ovary (CHO) cell line is of paramount importance for the chemistry, manufacturing, and controls (CMC) portion of studies that support investigational new drug (IND) applications (1, 2). Desirable attributes of a CHO cell line include its ability to produce high titers of biotherapeutic proteins facilitate quick recoveries and selection processes maintain phenotypic and genetic stability throughout in-vitro aging of a culture. A CHO cell line also should be scalable to high-capacity culture…

Retrofitting Your Bioreactor to Enhance Stirring Processes: Replacing Old Agitators with State-of-the-Art Magnetic Mixing Technology

A key challenge for companies involved in drug development is to meet the highest standards of sterile design and reliability. In this context, magnetic mixers offers many advantages for aseptic stirring processes compared to mechanically sealed agitators. ZETA not only supplies magnetic agitators for new bioreactors, but also supports its customers through the entire retrofitting process, from feasibility studies at the beginning to full process qualification and validation at the end. “Combat the risk of batch contamination in bioreactors and…

A Rapid, Low-Risk Approach Process Transfer of Biologics from Development to Manufacturing Scale

Successful scale-up of cell culture for manufacturing of biopharmaceuticals gives companies time to accelerate clinical development, product commercialization, and market access (1). Scaling a cell culture process in stirred-tank bioreactors ideally includes optimizing that process at laboratory scale and then transferring it through larger pilot-scale and finally to manufacturing-scale bioreactors (2). This is a complex, time-consuming business that can involve process transfer — sometimes to different geographical locations and through many sizes of bioreactors, each of which can operate according…

Ask the Expert: A Robust, Stable Platform for Biologics Development

Sean Liour (vice president for project management at GenScript ProBio) delivered an Ask the Expert presentation on 18 March 2020 to explore the advantages of his company’s platform for cell-line development. Liour explained that successful biologic development hinges on robust host cell lines, capable expression vectors, and discriminating clone-screening systems. Overviewing relevant technologies and capabilities, Liour illustrated how his company’s ProCLD platform helps sponsors navigate cell-line development. Liour’s Presentation Researchers must weigh their options carefully when selecting a host cell…

Navigating Technology Transfer

Technology transfer is a key milestone in the journey from discovery to full-scale good manufacturing practice (GMP)-compliant manufacturing. Navigating this step while preventing unforeseen issues that can create costly delays is supported best by combining knowledge of a given process with understanding of the technological capabilities. Different applications have different needs. Some challenges and goals are common to bioreactor processes for suspension and adherent cell culture for production of viral vectors, monoclonal antibodies (MAbs), other recombinant proteins, and vaccines. All…

Industrialize Your Viral Vector Production in Adherent and Suspension Cell Cultures: Know the Pros and Cons

This educational podcast, “The Evolution of Culture Systems for Viral Vector Production: Advantages, Challenges and Cost Considerations,” recently published by Cell and Gene Therapy Insights, discusses in detail the pros and cons of viral vector production in adherent and suspension cell culture. This special report illustrates how Pall Biotech’s iCELLis 500+ bioreactors and Allegro STR bioreactors can bolster adherent and suspension culture, respectively, for viral vector production. Fill out the form below to read the complete report and learn more now.…

BVDV Risk Mitigation: Dealing with Bovine Viral Diarrhea Virus in Serum

Bovine serum products such as fetal bovine serum (FBS) are critical, nutrient-rich supplements frequently used in cell culture systems for a number of applications, including biotechnology, animal and human pharmaceutical and diagnostic manufacturing, and life-science research. Serum can be contaminated with adventitious agents that could increase its risk for use in cell culture systems. Bovine viral diarrhea virus (BVDV) is one of the most significant infectious diseases in the livestock industry worldwide because of its high prevalence, strong persistence, and…