Process monitoring in laboratory and production environments enables continuous control and optimization of critical process parameters. Hence, the early detection of errors is an effective means of increasing process efficiency and reproducibility, improving quality and safety parameters, and reducing long-term costs. Highly precise and flexible noncontact clamp-on flow and bubble sensors are useful instruments to fulfill these goals. They can be applied effectively to buffer and media preparation, chromatography and filtration systems, bioreactors and fermentors, feed and transfer lines, and fill–finish applications.

Process monitoring in laboratory and production environments enables continuous control and optimization of critical process parameters. Hence, the early detection of errors is an effective means of increasing process efficiency and reproducibility, improving quality and safety parameters, and reducing long-term costs. Highly precise and flexible noncontact clamp-on flow and bubble sensors are useful instruments to fulfill these goals. They can be applied effectively to buffer and media preparation, chromatography and filtration systems, bioreactors and fermentors, feed and transfer lines, and fill–finish applications.

Clamp-On Ultrasonic Flow Meter

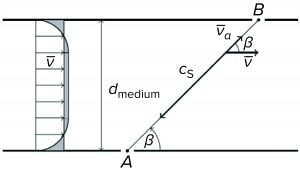

An Essential Tool to Measure Flow Rates Accurately Without Liquid Contact: One main advantage to applying ultrasonic technology for flow measurement is the ability to measure constant liquid flows independently of their charge, density, or viscosity (1). Ultrasonic liquid-flow measurement is especially useful for noninvasive applications. Noncontact flow meters can measure directly through the walls of flexible or rigid plastic tubes and pipes without interfering with flow or coming into contact with the process fluid (Figure 1). As long as liquids are acoustically transparent, an ultrasonic wave will propagate through them. Sound waves react sensitively to changes in or certain properties of matter permeated by an ultrasonic beam. This effect is exploited in the transit-time–difference method (2–4). An ultrasonic wave can be carried along or slowed down by a flowing medium in an “entrainment effect” that enables measurement of the fluid-flow velocity and indirectly the volume of flow.

Ultrasonic flow is measured over time, enabling calculation of a flowing liquid’s velocity. A key challenge in getting an exact flow volume lies in determining the cross-sectional area of flexible tubing. A Sonotec internal study was executed to evaluate how accuracy shifts when tubes of different materials, durometry, manufacturers, and/or innner:outer diameter (ID/OD) ratios are applied after a Sonoflow CO.55 flowmeter has been calibrated to a certain tube (5). Results demonstrated shifts ranging from one-digit percentage rates among different manufactures of the same tube material up to 50% for differing tube IDs. To ensure an accurate measurement, a sensor adjustment to specific tubes becomes necessary. Sonoflow CO.55 flow meters have optional software for performing such calibration processes.

Noncontact Bubble Sensors

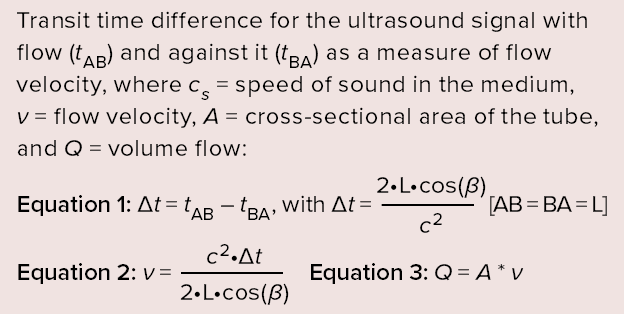

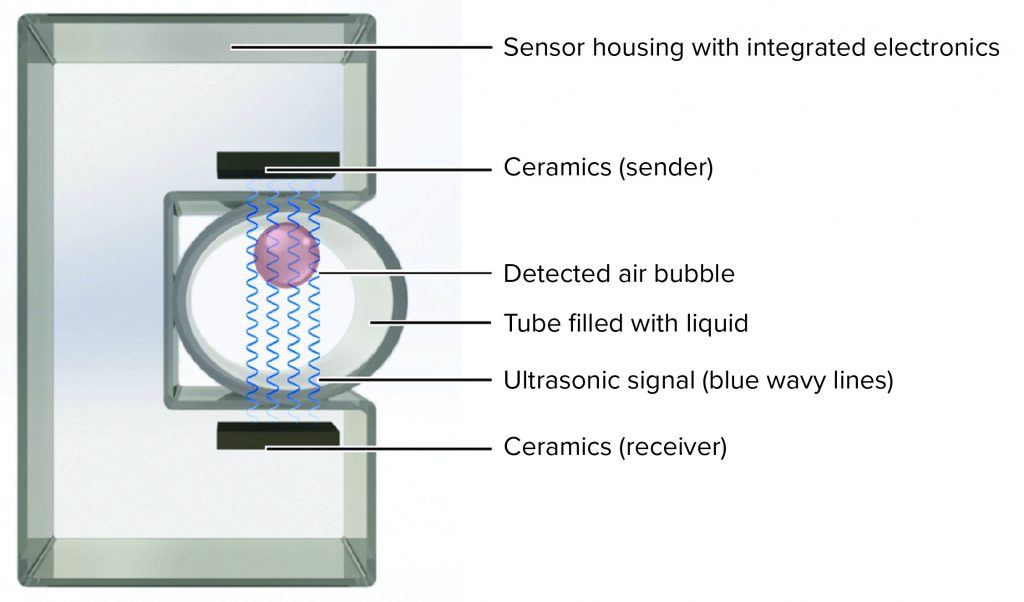

Clamp-on Systems for Precise Bubble Detection in Liquid Tubes: As illustrated in Figure 2, ultrasonic air-bubble detection is based on noninvasive measurement through the walls of flexible and rigid plastic tubes by transmission technology (6). The clamp-on architecture of these sensors enables noncontact measurement of the tubing interior. Simply insert a tube into the measuring channel of the sensor. Two transducers placed on opposite sides of the liquid-filled tube act as transmitter and receiver: The former generates an ultrasonic wave that moves through the tube perpendicularly to the liquid and reaches the latter on the opposite side of the tube. Because the acoustic impedance of air is ~3,500× lower than that of water, the reflection coefficient at the water–air interface is accordingly high, so most of the acoustic energy is reflected. In addition, ultrasonic waves are much more attenuated when propagating through air than through water. Both phenomena cause the amplitude of the receiver signal to decrease.

Acoustic transmission through the tube strongly depends on ambient conditions, so Sonotec has implemented a patented closed-loop algorithm to its Sonocheck ABD06 sensor series to counteract such effects and enable the sensors to adjust dynamically for guaranteed constant bubble sensitivity. Thus, bubbles will be detected reliably from a certain predefined size onward, with no dependence on tube setting, ambient humidity, temperature change, or potential tubing shifts. A built-in microcontroller provides smart and dynamic adaption of ultrasonic properties to ensure reproducible results. Sonocheck ABD06 bubble detectors benefit from the company’s long-term experience in developing medical-grade bubble detectors for hemodialysis and extracorporeal membrane oxygenation (ECMO) machines. Hence, the sensor can detect bubbles down to 0.3 µm in diameter and needs no calibration.

Not Just Ultrasound

Sonotec also possesses the expertise to manufacture piezocomposites, making its flow and bubble sensors the most accurate on the market. Ultrasonic transducers are the heart of every clamp-on ultrasonic flow sensor. They are made of piezoelectric ceramics or composites that expand or contract when a direct-current (DC) voltage is applied. With application of an alternating voltage, piezoelectrics expand and contract periodically to emit a sound wave corresponding to their excitation frequency. That wave is sent out as a pulsating ultrasonic beam from an excitation transducer for detection by a receiving transducer.

Piezocomposite material is an important upgrade to existing piezoceramics. A mixture of polymer and piezoceramic materials, composites can modify specific features of the ceramics by adjusting filling materials and ratios, for example. As a result, piezocomposites are elastically deformable and heat-malleable, and their piezoelectric characteristics can be adapted for specific applications. That provides for an optimal adaptation to the sound properties of different materials and interfaces when an ultrasound wave transmits from the transducer through the sensor channel, tube walls, and liquid inside a tube. The advantages of piezocomposites over ceramics are clear: optimized echosensitivity and mechanical flexibility, improved electroacoustic efficiency, reduced planar coupling, and low acoustic impedance.

Sonotec anticipated the advantages of composites over ceramics from the beginning and has been pooling its basic research expertise in an owned competence center. Hence, the company develops and manufactures its own measuring cells, implementing piezocomposites into all its flow and bubble-detector sensors.

References

1 Püttmer A, Linzenkirchner E, Hauptmann P. Ultraschallsensoren für die Prozesstechnik. Automatisierungstechnische Praxis 45, 2004: S51–S59.

2 Webster JG. The Measurement, Instrumentation, and Sensors Handbook. CRC Press: Boca Raton, FL, 1998.

3 Bonfig KW. Technische Durchflussmessung. Vulkan Verlag: Essen, Germany, 1987.

4 ISO 12242:2012. Measurement of Fluid Flow in Closed Conduits: Ultrasonic Transit-Time Meters for Liquid. International Organization for Standardization: Geneva, Switzerland, 2012.

5 Technical Note: Effects of Tubing Changes on Calibration of SONOFLOW Ultrasonic Flow Sensors. Sonotec GmbH: Halle (Saale), Germany, 2020; https://www.sonotec.eu/fileadmin/media/DE/Produkte/Nicht_Invasive_Fluessigkeitsueberwachung/Biotech/tn_effects_of_tubing_changes_en_sonotec.pdf.

6 Krautkrämer J, Krautkrämer H. Schattenverfahren (Intensitäts-oder Durchschallungsverfahren). Werkstoffprüfung mit Ultraschall. Springer: Berlin/Heidelberg, 1986.

Frauke Beelmann is marketing manager for noninvasive fluid monitoring at Sonotec GmbH in Halle (Saale), Germany; 49-345-13317-822; frauke.beelmann@sonotec.de. Sonoflow and Sonocheck are registered trademarks of Sonotec GmbH.