Roche Pharma Research and Early Development (pRED) was faced with a challenge: double the number of projects in process development without significantly increasing headcount. Pawel Linke, a pRED lab automation specialist, tells the story of how the group approached this challenge with a focus on obtaining high quality data through automation and by integrating independent lab systems and devices to streamline their workflow.

Roche Pharma Research and Early Development (pRED) was faced with a challenge: double the number of projects in process development without significantly increasing headcount. Pawel Linke, a pRED lab automation specialist, tells the story of how the group approached this challenge with a focus on obtaining high quality data through automation and by integrating independent lab systems and devices to streamline their workflow.

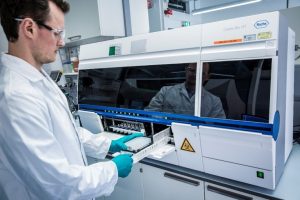

Implementation of high-throughput process development systems requires an orchestrated approach of both hardware and software solutions, so that data can be used in-process enabling efficient, development and decision making. This use case discusses the integration of parallel microbioreactors, robotic liquid handling (with Tecan Fluent), and the Cedex Bio HT Analyzer for bioprocess control.

A critical component to optimizing the high-throughput workflow was the development of the 96-well plate upgrade for the Cedex Bio HT Analyzer, which allows for simpler sample transfer from system to system. The Cedex Bio HT Analyzer utilizes enzymatic assays, enabling high robustness and sensitivity as well as optimized measurement ranges, adapted to the particular demands of cell culture and fermentation processes. Thus, you can rely on this instrument to capture useful and timely insights into your bioprocess and make the right decisions for optimal manufacturing outcomes. Currently, the Cedex Bio HT Analyzer can monitor 27 parameters including Glucose, Lactate, Ammonia, Glutamate, Glutamine, Human IgG, Ig Fab, calculated osmolality among others with additional assays in development. With the 96-well plate upgrade and latest software, a lab can achieve high quality, high throughput bioprocess monitoring with significantly less hands on time than before.

With hundreds of microbioreactors running at any given time in this high-throughput setting, tracking samples and maintaining data integrity can also be challenging. In order to keep track of samples moving from system to system, pRED utilizes a software called Sm@rtline Data Cockpit (SDC) provided by AGU, which acts as a mesh-like middleware between lab instruments and devices in the high-throughput workflow. Using this single user interface, which is linked to each of the lab systems and devices, the lab can easily trace samples throughout the workstream from the time the sample is pulled from the bioreactor, while the sample is being aliquoted for analysis liquid handler, and during analysis on the Cedex Bio HT Analyzer. The software also facilitates automated feedback control of critical process parameters (e.g. Glucose). All of these systems work in harmony to increase the number of proteins developed at pRED, truly making the new workflow solution a smart path for novel biologics.

Regulatory disclaimer

For use in quality control/manufacturing process only.

Trademark

CEDEX is a trademark of Roche.

All other trademarks and brand names belong to their respective owners.