The digital revolution in manufacturing began with an explosion in monitoring, analytics, and new computing capabilities. Combined with such advances as artificial intelligence (AI), automation, and robotics, they are changing our concepts of manufacturing in general — from product development and factory operations to materials supply. This evolution also connects product and process designers and leaders in manufacturing engineering. Digital manufacturing (DM) isn’t a dream or a concept on some advanced developer’s design table; it’s occurring now and will change industry forever (1, 2).

For many years, manufacturing plants have been generating more and better data than ever before. But some companies have begun harnessing the resulting sea of information to gain valuable insights that can lead to greater efficiencies, productivities, and growth (3). Recent advances in the discipline of asset performance management owe much to the digital manufacturing revolution (4).

The general public sees this type of development embodied in the self-driving car. We understand that not only do these cars generate large amounts of data regarding their surroundings, but that information is being managed by advanced control systems that can interpret it to distinguish things on the road and set a path forward. Such cars are moving beyond highly automated to becoming autonomous.

Digital manufacturing can heighten the productivity and robustness of existing processes and facilities. It also enables efficient development of some previously unmanageable products or processes. DM is a local and online means for continuous optimization of process performance. This functionality is based on information derived from current operations and that from previous batches or periods of operation. It relies on the comprehensive, real-time interfacing of both human- and machine-sourced information through one centralized system.

| Â What is Digital Manufacturing? |

|

More than legacy distributed control system (DCS) and supervisory control and data acquisition (SCADA), DM requires an integral interconnection of real-time access to divergent sources of information. Thus, it can enable deep analysis and predictions leading to advanced process control. Such comprehensive analyses extend beyond operation-performance data from a production floor to data that drive such activities as raw materials security of supply (SoS) and business continuity management systems (BCMS) (5).

The Predix system offered by GE Digital is an example of how manufacturers can use continuous data acquisition, cloud technology, and advanced analytics to provide a platform for the industrial Internet. The software feeds data from new sensors and other high-value sources such as process history records into advanced process-control algorithms. From those, manufacturers can gain actionable intelligence, transformative insights, and improved process control (6).

The availability of such tools as ultrafast digital processors, inexpensive and flexible data storage, advanced analytics and control algorithms, and even AI are providing heretofore unheard-of insights into manufacturing processes. Now companies can know specifically what is happening based on a dozen measured parameters in every part of an operation and in real time. Powerful computers then can predict and control the critical operational parameters of those processes. Small-molecule drug manufacturers already use such understandings to invent end-to-end processes for continuous manufacturing.

Digital Biotechnology

The “digital” concept is applied in many areas of biotechnology. Although each of those involve millions of discrete values (digital) and most use living cells or their immediate parts (biologics), biotech companies are approaching digital biotechnology from a number of different angles. It’s becoming important to understand and distinguish a few related terms and digital approaches. On one hand, for examples, computers can direct recombinant and synthetic biology to build living structures component by component; on the other hand, nucleic acids themselves are promoted as a potential means of high-density data storage.

DNA Digital Data Storage: There are multiple methods for building a computing device based on deoxyribonucleic acid (DNA) molecules. Each offers its advantages and suffers disadvantages, and approaches vary in both the molecular means of memory and the mathematics used to operate them. However, most technologies use transcription-based memory and familiar binary digital logic (7).

Digital Gene Circuits: Some researchers are applying synthetic gene-circuit technology to metabolic engineering that could enable cells to respond dynamically to user inputs or environmental signals. That would provide enhanced control of bioproduction processes. Developers are exploiting natural digital-memory pathways and such existing natural factors as regulatory ribonucleic acid (RNA) and transcription factors to devise circuits that switch between specific cellular states. Some are even designing such optional features as memory multiple-signal integration (8).

Digital Polymerase Chain Reaction (PCR): Digital PCR allows scientists to screen for a single target molecule among millions of background molecules. This works by partitioning a sample of DNA into many small, individual, and simultaneous PCR reactions. Only very few of those isolated reactions contain the target DNA, whereas the vast majority will not. Portioning off many small reactions reduces background DNA in the reaction to a desired level. Several means of such portioning are available, ranging from microwell chips to microfluidic “bubbles” of reactions. At least one vendor is suggesting a means of collecting the amplified needle-in-a-haystack product — which could provide a form of microbioproduction (9).

Microfluidics: Many applications of “organ-on-a-chip” technology do not involve either/or decisions. The “chip” here is simply a miniaturized reaction device required for speed, convenience, and economy. But micro- and nanofluidic activities often do involve a switching function to create two alternative states (or “pools”) of product. So these are truly digital activities that use a “chip” of sorts to produce them (10).

| Definitions |

| Analytical quality by design (AQbD): concepts described in ICH Q8–Q11 as applied to the development of analytical methods |

| Big data: information sets that are so large and complex that traditional data-processing methods are inadequate to handle them (see “How Big Is Big Data?”, below) |

| Business continuity management system (BCMS): a digital framework for building and administering a business continuity program (for prevention of and recovery after performance threats) within an organization |

| Cloud computing: using a network of remote servers hosted on the Internet to store, manage, and process data — rather than a local server or individual computer |

| Distributed control system (DCS): a hierarchical process control system with elements located not only in a central location but also distributed throughout the process train, in which each component subsystem is managed by one or more controllers so that intelligence is distributed across the plant |

| Digital polymerase chain reaction (D-PCR): refinement of conventional PCR methods that directly quantifies and clonally amplifies individual nucleic acid strands — but improved precision makes it more prone to error for inexperienced users |

| Enterprise resource management (ERM): software that administers all of a company’s assets and resources including purchasing, production planning, manufacturing, and shipping |

| Industrial internet of things (IIoT): uses machine learning and big data technology to harness sensor data, machine-to-machine communication, and automation technologies in manufacturing; “Internet of things” specifically describes a system of interrelated computing devices, mechanical and digital machines, objects, or living things that provide for the transfer of data over a network without requiring human-to-human or human-to-computer interaction |

| Object linking and embedding (OLE): Microsoft’s framework for a compound interface technology linking visual and information objects of all kinds (e.g., text, files, calendars, sound, 3-D video, and continually updated information and control data) |

| OLE for process control (OPC): a series of standards and specifications for industrial telecommunication developed in 1996 by an industry task force to specify the communication of real-time plant data among control devices from different manufacturers |

| Supervisory control and data acquisition (SCADA): a control system architecture combining computers, networked data communications, and graphical user interfaces (GUIs) for high-level process supervisory management, using peripheral devices such as controllers for interfacing with a process plant or its machinery; operators interface with the supervisory computer system while real-time control logic or controller calculations are performed by networked modules connected to field sensors and actuators; developed as a universal means of remote access to a variety of local control modules from different manufacturers through standard automation protocols |

Direct Digital Biomanufacturing

Direct digital biomanufacturing (DDM) covers processes from direct assembly of nucleic acids or proteins to three-dimensional bioprinting (3DBP) of functional tissues or cellular arrays from whole cells (11). 3DBP uses computer algorithms and modeling to direct deposition of fluids containing (or immediately impregnated with) living cells (or cell assemblies) with nutrients and structural matrices —creating multicell deep constructs.

Such printed constructions can be used in all sorts of research, diagnostic, and even medical applications. One application uses new software developed to manage imported images for designing, visualizing, simulating, and analyzing 3D computer models of structures to be printed. One implementation would be to use such medical scans as magnetic resonance imaging (MRI) to guide the printing of tissues for internal organ repair. Another would be to use digital files from laser imaging to guide in situ printing of skin-cell–based “bioinks” that close wounds (12).

Some researchers are generating both in silico printed physical and 3D models for use in diagnosis and (surgical) therapy preparation (13). The newest approaches to tissue printing incorporate multiple bioinks in multistep and multimode printing. Maintaining many bioinks and constructs while using multiple and distinct printing technologies will demand a higher level of process control and equipment integration than is currently available. But as the promise of biomedical applications through bioprinting is fulfilled, advanced information management factors will enable processes to generate improved documentation and lessen risk.

Finally, to protect cells both within bioinks and tissue constructs, we are seeing active control of many environmental parameters before, during, and after printing (14). As 3DBP begins to realize the promise of such therapeutic applications, advanced digital approaches will enable more efficient, reproducible, and self-adaptive processes (15).

Digital biomanufacturing (DB) can be viewed as yet another — potentially larger — embodiment of digital biotechnology. DB is similar to DM in that it promotes improvements in the manufacturing of biologicals by using such things as computer-aided design, manufacture, and verification (16, 17). However, the living components (cells) involved in bioprocesses impart a distinctly different character to the systems involved here. We use a distinct term to distinguish DB because (as with the terms bioproduction and biopharmacology) it addresses the unique aspects of biological activities.

In DB we are seeing most of the same specific advances as in DM: increased monitoring, data collection and handling, connectivity, computer power, process control algorithms, and automation. However, bioprocessing also addresses the unique requirements of living cells and their products. Upstream, that includes dynamic control of a changing ambient environment as well as a cell culture’s metabolic state and total mass. Downstream, it can include assessment of lot-variant harvest compositions and consequent adjustment of process inputs for critical parameter control. Downstream processes also must allow for variability in the amount, state, and quality of intermediate products.

DB is part of an evolution: one further step in the development of the industrial internet of things (IIoT), which connects disparate sources of data and uses advanced analytics to turn them into actionable insights. IIoT refers to instruments becoming interconnected — but more than that, it denotes high levels of data analysis, information management, and process control being implemented into a “process network.” DB promises such things as real-time optimization of manufacturing processes based on highly valuable criteria such as projected product quality and batch profitability. DB software increases asset reliability and availability while reducing maintenance requirements. In addition to new data-gathering and interfacing techniques from advanced computer hardware, object linking and embedding (OLE) for process control (OPC) and cloud capabilities are producing a qualitative change in our capability to understand an entire biomanufacturing process. DB promotes collaboration and knowledge management across an entire organization.

Joel Sirois (CEO of BioIntelligence Technologies Inc.) says, “One of the many distinct benefits digital biomanufacturing will enable is the real-time optimization of the end-to-end manufacturing process based on such highly valuable criteria such as projected product quality” (18). DB promises optimization and continuity of operations by providing real-time access to critical information through high-demand manipulation and analysis of rich, timely data.

Supporting Technologies

Big Data: Increased power in information handling and processing began with dramatic increases in microprocessor speed, pipelining, and parallelism over the past couple of decades (19). The trend continues with advances in data-handling software and device interfaces (20). The phenomenon of “big data” refers to information sets that are so large and complex that traditional data-processing methods are inadequate to handle them. Advanced methods of extracting value from huge data sets is a key development enabling DB. The resulting power promises to vastly improve operational efficiencies, reduce costs, and lower risk in bioprocessing.

| How Big Is “Big Data?” |

|

|

| Sources http://www.cisco.com/c/en/us/solutions/collateral/service-provider/visual-networking-index-vni/vni-hyperconnectivity-wp.html http://highscalability.com/blog/2012/9/11/how-big-is-a-petabyte-exabyte-zettabyte-or-a-yottabyte.html |

The Cloud: A key to the future in advanced bioprocessing control is cloud computing. Internet-based systems provide shared computer processing power and data on demand. The cloud can enable on-demand access to a shared pool of all sorts of configurable computing resources. It also can provide access to resources that are geographically located far from users.

Lean Product and Process Development (PPD): Lean PPD is gaining influence in the development of bioprocess understanding. Practical advances such as solid-state memory and cloud computing enable this progress. Heightened bioprocess knowledge and establishment of critical control parameters (CCPs) synergize with statistics-based analysis and design approaches in product and process development. The emerging field of analytical quality by design (AQbD) supports lean PPD with advanced process engineering techniques, new analytical equipment, testing capabilities, and science-based approaches (21, 22).

Sensor Technologies: Increased availability of real-time data is feeding improved closed-loop control systems that can alter CCPs robustly. The digital revolution in biomanufacturing began with improvements in process monitoring capabilities. That generated large amounts of data relating to more aspects of bioprocessing. Innovations driven by process analytical technology (PAT) include a number of light-based probes and automated cell-free sampling devices.

Progress in biochemistry, photonics, and information technology has promoted powerful chemical optical sensors for bioprocess monitoring. Even single-use sensors are emerging in designs that enable in situ, real-time monitoring of important culture parameters without sampling. These advances are based on several physical properties and constants of recently engineered materials and the biological components that they measure. New advantages include miniaturization, flexibility, embedded sensing, rapid at-line sensing, multisensing, and continuous quantitative or qualitative measurements. From very small sensor spots to robust dipping probes, chemical optical sensors can monitor a number of culture parameters online throughout culture duration.

The availability of single-use, cell-free multiplex sampling technologies is an enabling factor in generating near–real-time process information. Previously, many culture-monitoring and potentially controllable process attributes often were ignored because near–real-time digital data were unavailable. But that is changing. For example, GE Healthcare’s Biacore surface plasmon resonance (SPR) system can characterize monoclonal antibodies (MAbs) in terms of their specificity, kinetics, and affinity. Other new systems can provide near–real-time concentration measurements of bioprocess components using, for example, a calibration-free concentration analysis (CFCA) method. Concentrations now can be measured in the nanomolar range (23).

Process Control: Advanced algorithms, increased processing speeds, and the large amounts of process data available are changing not only the power of process control systems, but also their scope. Adaptive “fuzzy expert” systems use AI to provide powerful and robust models that predict operation control. This is especially important in bioreactor control because cells not only change their ambient culture media, but they themselves also respond dynamically to the changes that result. That foundation supports brilliant software that implements new mathematical, statistical, and logical algorithms.

For example, GE Healthcare’s Unicorn system control software provides built-in knowledge for planning and controlling process runs by analyzing results from a number of bioproduction operations. Such software is suitable for use in regulated environments because it provides traceability and back-up functionality as called for in 21 CFR Part 11, for example. Beyond that, distributed control elements and supervisory systems are enabling companies to consider such exciting innovations as end-to-end continuous biomanufacturing.

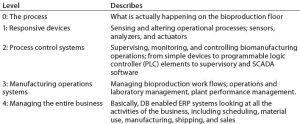

Enterprise Control: Once only a dream, enterprise control systems now provide coordination of every aspect of a business. As computer systems and AI become more powerful, enterprise control is becoming more automated. An international control has been published for this: the ISA-95 standard from the International Society of Automation (24). Table 1 outlines the levels of activity in an entire biomanufacturing process. Enterprise resource planning (ERP) often describes a suite of integrated applications that biomanufacturers can use to collect, store, manage, and interpret data from product planning, purchasing, manufacturing, marketing, sales, inventory management, shipping, and finance. ERP provides an integrated view and control of those business processes — often in real-time — using a common database.

Innovation Is Alive and Well

New and optimized manufacturing technologies such as continuous biomanufacturing and 3D bioprinting can demand the interfacing of many sources of information, deep data analysis, and model-based predictions of DB. Older platforms are greatly improved by them as well. Four essential benefits result from increased bioprocess understanding, development, and control. First, personnel are relieved of many manual and repetitive tasks. Second, strategic planning and operational efficiency are improved. Third, real-time optimization of end-to-end manufacturing is based on such high-value criteria as projected product quality and batch profitability. And finally, DB can enable previously unmanageable operations and processes.

| What Is Digital Biomanufacturing? |

|

Drivers

|

IT Enablers

|

Biotechnology Enablers

|

References

1 Dazhong Wu, et al, Cloud-Based Design and Manufacturing: A New Paradigm in Digital Manufacturing and Design Innovation. Comp.-Aided Des. (59) 2015: 1–4; doi:10.1016/j.cad.2014.07.006.

2 DN Staff. GE Is About to Invade Digital Manufacturing with “Brilliant” Move. Design News 22 October 2015; www.designnews.com/automation-motion-control/ge-about-invade-digital-manufacturing-brilliant-move/194674454545908/page/0/1.

3 Agarwal N, Brem A. Strategic Business Transformation Through Technology Convergence: Implications from General Electric’s Industrial Internet Initiative. Int. J. Technol. Managem. 67(2–4) 2015: 196–214.

4 Parida A. Performance Measurement and Management for Maintenance: A Literature Review. J. Qual. Mainten. Eng. 21(1) 2015: 2–33.

5 Business Continuity Planning. Wikipedia, https://en.wikipedia.org/wiki/Business_continuity_planning.

6 The World Runs on Industry, and Industry Runs on Predix. GE Digital: San Ramon, CA; www.ge.com/digital/predix.

7 DNA Digital Data Storage. Wikipedia, https://en.wikipedia.org/wiki/DNA_digital_data_storage.

8 Roquet N, Lu TK. Digital and Analog Gene Circuits for Biotechnology. Biotechnol. J. 9(5) 2014: 597–608.

9 Digital Polymerase Chain Reaction. Wikipedia, https://en.wikipedia.org/wiki/Digital_polymerase_chain_reaction.

10 Basic Microfluidic Concepts. Wikipedia, http://faculty.washington.edu/yagerp/microfluidicstutorial/basicconcepts/basicconcepts.htm.

11 Servick K. Rise of Digital DNA Raises Biopiracy Fears. Science 17 November 2016: www.sciencemag.org/news/2016/11/rise-digital-dna-raises-biopiracy-fears; doi:10.1126/science.aal0395.

12 Sanjairaj V. 3D Bioprinting of Skin: A State-of-the-Art Review on Modeling, Materials, and Processes. Biofabrication 8(3) 2016: 032001; doi: 10.1088/1758-5090/8/3/032001.

13 Göttlich C, et al. A Combined 3D Tissue Engineered In Vitro/In Silico Lung Tumor Model for Predicting Drug Effectiveness in Specific Mutational Backgrounds. J. Vis. Exp. 110, 2016: e53885; doi:10.3791/53885.

14 Whitford W, Hoying JB. Digital Biomanufacturing Supporting Vascularization in 3D Bioprinting. Int. J. of Bioprinting March 2017: in press.

15 Alves N. Advances in Direct Digital Biomanufacturing Systems for Tissue Engineering. International Conference on Direct Digital Manufacturing and Polymers (ICDDMAP): Dharwad, India, 2015; www.researchgate.net/publication/285054521_Advances_in_direct_digital_biomanufacturing_systems_for_tissue_engineering.

16 Fan H, Scott C. From Chips to CHO Cells: IT Advances in Upstream Bioprocessing. BioProcess Int. 13(11) 2015: 14–29.

17 Kaplan D, et al. Advanced Biomanufacturing: A Workshop. National Science Foundation: Arlington, VA, 2013; www.nsf.gov/eng/cbet/documents/adv_biomanufacturing.pdf.

18 The BioAnalyst™. BioIntelligence Technologies: Sherbrooke, QC, Canada, 2017; http://biointelligence.com/products/bioanalyst.

19 Patterson JRC. Modern Microprocessors: A 90-Minute Guide. Literra: Surfers Paradise, QLD, Australia, May 2015; www.lighterra.com/papers/modernmicroprocessors.

20 Schmitt S. Information Instead of Data: User-Friendly HMI Concept Increases Process Control Efficiency. BioProcess Int. 13(5) 2015: 42–46.

21 Chi B, et al. Multiproduct Facility Design and Control for Biologics. BioProcess Int. 10(11) 2012: S4–S14.

22 Jain S. Process Effectiveness Analysis: Toward Enhanced Operational Efficiency, Faster Product Development, and Lower Operating Costs. BioProcess Int. 12(10) 2014: 18–20.

23 John GT. Using Optical Sensors for Bioprocess Monitoring: A Measurement Technique for Bioprocessors. BioProcess Int. 14(3) 2016: S45–S48.

24 Automated Interface Between Enterprise and Control Systems. Wikipedia, https://en.wikipedia.org/wiki/ANSI/ISA-95.

Further Reading

Adkins M. Hurry Up and Wait? You Can Finish the Paperwork Shortly After a Product Is Manufactured. BioProcess Int. 8(1) 2010: 10–16.

Brown F, Hahn M. Informatics Technologies in an Evolving R&D Landscape. BioProcess Int. 10(6) 2012: 64–69.

Moore C. Harnessing the Power of Big Data to Improve Drug R&D. BioProcess Int. 14(8) 2016: 64; www.bioprocessintl.com/manufacturing/information-technology/harnessing-power-big-data-improve-drug-rd.

Editorial advisor William Whitford is strategic solutions leader at GE Healthcare Life Sciences, 925 West 1800 South, Logan, UT 84321; 1-435-757-1022; william.whitford@ge.com.