Normal-flow filtration is used throughout downstream processes for biologics including depth, sterile, and viral filtration applications. Because of its ubiquity in large-scale biomanufacturing, using the most efficient normal-flow filter media area and type can lead to significant cost savings. To determine the most effective media type and area, developers use a scaled-down process model is used in bioprocess laboratories to minimize material requirements. Constant–flow-rate filter evaluations involve direct scale-down parameters that match manufacturing-scale process conditions. This type of evaluation can be time consuming, labor intensive, and complicated because of a lack of specialized laboratory-scale equipment. Clearly an integrated and semiautomated system would facilitate the efficient evaluation of filter media for manufacturing-scale bioprocesses.

PRODUCT FOCUS: BIOLOGICS

PROCESS FOCUS: DOWNSTREAM PROCESSING

WHO SHOULD READ: ANALYTICAL AND PROCESS DEVELOPMENT PERSONNEL

KEYWORDS: SCALE-DOWN, FILTER MEDIA, MABS, SCALE-UP, PERISTALTIC PUMPS, DIAPHRAGM PUMPS, AUTOMATION

LEVEL: INTERMEDIATE

Genentech Inc. and PendoTECH collaborated on developing an integrated filter-sizing system that addresses several disadvantages of the equipment commonly used. Those disadvantages included poor integration of multiple components from different sources (including pressure sensors, signal conditioning, data acquisition, balances, and pumps), continuous operator monitoring, and decreased portability of most systems due to their numerous components. In addition, peristaltic pumps have been the primary scale-down model for constant-flow filter-sizing applications. Such pumps require frequent calibration and can have difficulty maintaining flow rates at high back-pressures. Screening multiple media types from different vendors can require a range of flow rates because of varying scaled-down areas available. That requires multiple peristaltic pumps to supply needed flow rates, further reducing system portability and increasing laboratory space requirements for process development.

System Development and Specs

Several requirements shaped development of our filter-sizing system to address those disadvantages of existing equipment used for such applications. Genentech desired the following characteristics of its new laboratory-scale system to efficiently perform normal-flow filter sizing and screening experiments:

- Can be easily purchased from one vendor with direct technical support

- Can control four independent filtration trains

- Can monitor and record three pressures from each train

- Should automatically stop a filtration train when a target volume or maximum filtration pressure is reached

- Uses high-precision pumps that eliminate the need for table-top balances to measure flow rate

- Operates at pressures ≤40 psig and flow rates of 1.0–20 mL/min

- Is controlled by a simple, graphical user interface (GUI) with user-friendly data retrieval and manipulation

- Offers real-time trending of process values

- Can be moved (portability) easily.

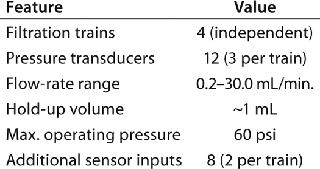

PendoTECH had worked on many systems for filter sizing and offers customized systems for process control solutions and/or data acquisition through its PendoKIT program. We used that program as the building block for developing our control system. It was designed to simultaneously record data from as many as 12 pressure sensors (through high-resolution analog inputs), control four pumps (through relay control and analog outputs or digital control), record data from four optional balances (through Recommeded Standard 232), and connect to a PC through two data ports (also RS232). Pressure sensors, pumps, and balances were arranged to enable four independent filtration trains, each capable of controlling one pump, measuring three pressures, and reading one balance if needed.

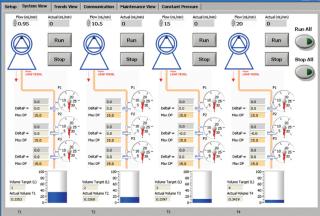

PendoTECH follows the good automated manufacturing practice (GAMP) lifecycle in development of its automated systems to manage the process from user requirements to system build. Based on Genentech’s needs and additional requirements from the vendor, we finalized a design specification and put the system into production after extensive real-world testing. The standardized normal-flow filter screening system design included a control module and pump module (Photo 1).

The entire control module is housed in one box with electrical connectors on its back panel designed to interface with sensors, pumps, and other instruments. At the core of the control module is a dedicated, programmable, high-performance microcontroller that uses firmware stored in radom-access memory (RAM) with a battery back-up. Embedded firmware in the control system stores process parameters entered from the GUI, controls pumps, reads sensors and scales, and monitors process conditions. This control system has a keypad and liquid crystal display (LCD) primarily used to enable nonstandard configurations.

We included a PC-based GUI (Photo 2) in our specification for user friendliness, and it allows complete control of the pump module. The GUI operates from a local PC and can be operated from outside a laboratory through remote-desktop applications. Through the GUI, users specify key process parameters such as maximum filtration train pressure, maximum differential pressure across each filter, and volumetric end-points for each filtration train. When a given set-point is reached, the corresponding pump automatically stops. For example, an audible alarm sounds when a pressure limit is reached, and the GUI highlights the affected filter and stops its corresponding pump automatically. The GUI records experiment-specific information such as filter names, filtration train names, and experimental notes. It can display real-time experimental data such as flow rate, differential pressure, flux, and filter permeability. Full manual pump control is also possible through the GUI. These functions (and more) are distributed across six easily accessed tabs that users can select.

Photo 1:

Photo 2:

Whereas the control module is the “brain” of this filter-sizing system, the pump module is its “heart.” To maintain portability of the integrated system, this pump module interfaces seamlessly with the control module and houses four high-precision diaphragm pumps. They are all digitally controlled using serial connections that allow precise flow control at low flow rates, which eliminates the need for bench-top balances to measure dispense volumes.

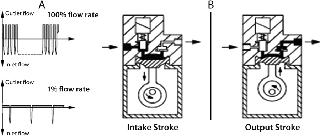

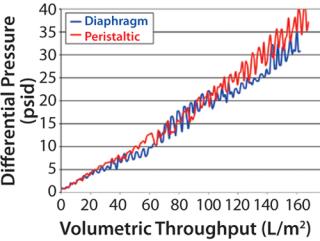

Although peristaltic pumps are typically used in filtration studies, we learned that diaphragm pumps provided similar results for reduced shearing of the protein feedstocks used in filtration experiments. A stepper-motor–driven diaphragm pump from KNF Neuberger provided the required accuracy and precision along with low shear in a compact design needed for our pump module. This pump also has low pulsation because of its unique operating method, in which the intake stroke is much faster than a varied output stroke so liquid can be evenly dispensed (Figure 1). The added accuracy, precision, and small footprint of this diaphragm pump simplified our system design. Flow rate and volumes can be automatically calculated by the control system rather than measured with bench-top balances, which were required with peristaltic pumps because of their inaccurate flow rates over the duration of filtration experiments.

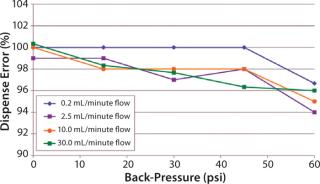

The operating range of the diaphragm pumps in our pump module is 0.2–30.0 mL/min. They are designed for minimum flow loss when pumping against higher pressures. Pump hold-up volume is ~1.0 mL with inlet and outlet tubing. All product-contacting internal pump components are fluoropolymer based, which provides a broad range of chemical compatibility.

PendoTECH manufactures pressure sensors ranging from luer size to 1-in. diameter that can be used with this normal-flow filter screening system or stand-alone monitors. These sensors are economical enough to be disposed of after biohazardous studies, but also robust enough to be reused during development work. Although most disposable pressure sensors come in polycarbonate housings, these also come in polysulfone for caustic sanitization. A Fully Integrated System

Integration of pump and control modules — along with precise pressure sensors — provides for complete control of experimental parameters. Tests can be run without constant human monitoring to prevent excessive pressures or exhaustion of feedstock. If any filtration train reaches its pressure and/or volume set-point and stops, the other filtration trains will continue to operate without interruption. Reduction in the number of physical components shortens set-up time and makes the equipment easily portable to remote locations. Because this system is fully integrated, it captures all data in one comprehensive but easy-to-analyze file. With a consistent format of such data files, we can use templates and rapidly produce relevant graphs for data analysis.

The GUI is unique to this system. It consolidates all experimental set-up, pump control, data trending, system communication, and maintenance functions into six tabs. Beginning an experiment with four unique filtration trains, twelve filters, and twelve pressure transducers can be accomplished by clicking a single button. The ability to run four independent trains from the GUI enables rigorous head-to-head comparison of filters using a common feedstock or multiple filter configurations using a range of feedstocks.

Pump Module Development and Comparability: Peristaltic pumps are typically used for filter sizing and screening experiments in downstream process development. However, tubing durability, pump-head variation, and flow decay at increased pressures can lead to inaccurate filter sizing and screening results. Because of the limitations of such pumps for these applications, we considered several different types of pumps in development of our pump module.

We compared the performance of diaphragm, piston, rotary-piston, and peristaltic pumps using monoclonal antibody (MAb) solutions. These solutions were filtered through a 0.22-µm polyvinylidene fluoride (PVDF) filter using each pump type, and only the diaphragm pump consistently matched the performance of the peristaltic pump in terms of solution filterability. We chose the diaphragm pump for filtration of protein feedstocks because it offered several performance advantages intrinsic to the pump design. KNF Neuberger’s diaphragm pump head features low pulsation at a range of pump speeds as well as precise flow control and dispense volumes over a wide range of flow rates and backpressures. We conducted further studies to show that its product filterability impact was comparable to that of the peristaltic pump typically used in filter sizing.

Figure 2 shows the accuracy and performance of our diaphragm pump module at a range of flow rates and backpressures. The pump module delivers accurate flow performance across a wide range of flow rates against pressures typically observed for MAb solution filtration experiments (~40 psi).

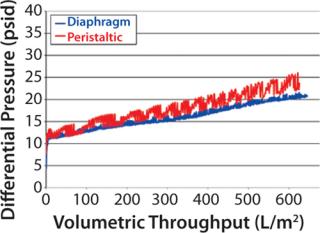

To demonstrate the comparability of our diaphragm pump module with peristaltic pump performance, we filtered MAb feedstocks through several filter types using both pumps. Their performance was comparable as measured by the filter-fouling profiles in Figure 3A–3C. This evaluation demonstrates comparable performance for both pumps. Although we observed comparable fouling profiles in our study, laboratory-scale pumps may not demonstrate filterability profiles for certain product solutions comparable to manufacturing-scale pumps. As with any scale-down pump, comparability studies should be performed to ensure accurate scale-up.

ve/00160/BPI_A_110906AR07_O__160953b.jpg”/>

ve/00160/BPI_A_110906AR07_O__160953b.jpg”/>

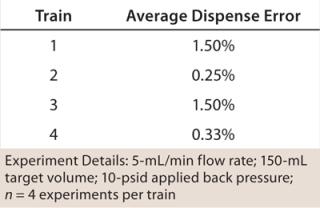

Table 1 shows the precision of our pump module for all four pump trains. Although the pump-head orientation allows for purging of entrapped air, we established a 30-mL/min (maximum flow rate) pump head priming procedure to ensure consistent dispense-volume performance. After sufficient priming, all four pump trains achieve very low dispense errors and deliver precise dispense volumes.Table 1: Average pump module dispense errors

Table 2: PendoTECH normal-flow filter screening system overview

Control System Flexibility

Peristaltic Pump and Bench-Top–Scale Application: To accommodate the wide range of normal-flow filtration applications, our control module has numerous built-in capabilities beyond its default configuration. If needed, the control system and GUI can be used to control peristaltic pumps remotely. A user enters the maximum flow rate for a pump–tubing combination into the control system and sets the analog output signal based on those entered settings and maximum flow. All experimental set-ups and pump operations are identical to those used with the pump module. Users can enter a measurement of total volume filtered as an optional setting. Total volume is calculated either by flow totalization (as when the pump module is used) or by filtered volume measurement with bench-top scales that can be connected to the back of the control system.

In-line Sensors and Devices: Builtin connection ports on the back panel of the control system enable use of other devices with mA or voltage outputs. Turbidity sensors, RTDs, pH and conductivity probes, proximity switches, level sensors, liquid sensors, bubble detectors, flow meters, or other devices can be interfaced with this system. Eight total analog inputs (two per train) can be used in the range of 0–10 V or 4–20 mA. With that feature enabled, data from the inputs are displayed by the GUI system view and logged to the main data file with all other process data.

Feedback Flow Control: In addition to constant flow control, this system can run pumps under feedback control, in which a signal relays pressure data to the control system to vary the pump speed once it reaches a designated pressure set-point. This feature can be useful for achieving a maximum volumetric Figure 3Bthroughput before filter fouling in validation studies, for example. Selecting the “PRESSURE CONTROL” button in the experimental set-up tab on the GUI enables this feature, and each train can be configured with a different pressure set-point.

Constant Pressure Application: For additional versatility, a “CONSTANT PRESSURE” tab on the GUI screen allows for experiments with intentional filter fouling carried out under constant pressure. Taking advantage of the ability to read four scales, the system automatically plots time and volume data at a fixed pressure and performs real-time calculations during the experiment.

Improving Process Development Genentech and PendoTECH worked together to develop and produce an integrated and semiautomated system that aids in efficient evaluation of filter media for manufacturing-scale processes. This normal-flow filter sizing system is widely adopted across the global Genentech network, where it has been used for a broad range of filter sizing and screening applications. Implementation of the system has increased productivity in process development. It has been invaluable for early and late-stage process development as well as supporting commercial downstream processes

Author Details

Brian Kluck is an engineer II in process technical development, and Binh Thai is an engineer II in device development at Genentech Inc., 1 DNA Way, South San Francisco, CA 94080; thai.binh@gene.com. Corresponding author Jim Furey is general manager, and Dennis Annarelli, PhD, is technical manager at PendoTECH, 66 Witherspoon Street, Suite 256, Princeton, NJ 08542; 1-609-799-2299, fax 1-609-784-7889, jim@pendotech.com; dennis@pendotech.com