Single-use (SU) components are widely accepted in bioprocessing due in part to improvements in component design, a wider range of products, and increased scalability. Benefits driving their increased use include elimination of cleaning, improved system flexibility, and reduced risk of contamination.

Nonetheless, companies now question how far disposables can be incorporated into bioprocessing unit operations. Results of the second annual survey of the bioprocessing market fo single-use solutions showed that >90% of respondents considered filtration well suited for single-use processing, compared with 54.5% for chromatography and only 24.2% for centrifugation. Nearly 72% of survey participants indicated the purification applications they would be most interested in using in a single-use approach was tangential flow filtration (TFF). Applications incorporating TFF, in part or fully, also gained high scores (59.3% for diafiltration and 65.6% for concentration).

PRODUCT FOCUS: ALL BIOLOGICS

PROCESS FOCUS: DOWNSTREAM PROCESSING

WHO SHOULD READ: PROCESS DEVELOPMENT AND MANUFACTURING

KEYWORDS: DISPOSABLES, FILTRATION, AUTOMATION, PAT

LEVEL: INTERMEDIATE

Such interest in TFF reflects the method’s complex nature and extensive cleaning requirement. Requirements for higher pressures, recirculating flow paths, pumps, valves, sensors, and so forth also present a challenge for developing a single-use operation.

Cleaning a TFF cassette and system is an essential step in maintaining flux rates and minimizing cross-contamination risk in a multiproduct system. Such a cleaning procedure demands detailed and validated standard operating procedures (SOPs). Cross-contamination risk can be eliminated either by dedicating a specific cassette to a specific product type or by applying a single-use policy, although the latter can present a financial constraint. Nevertheless, these options have been introduced into a range of TFF applications to prevent cross-product contamination and have been especially beneficial for contract research (CRO) and contract manufacturing (CMO) operators. For other product-wetted components — including pumps, valves and sensors — increasing availability of single-use alternatives that meet acceptable performance and cost targets offers possibility of a total single-use TFF system.

Development Strategy

Our approach to developing a single-use TFF system focused on system design, operating capabilities, and automation.

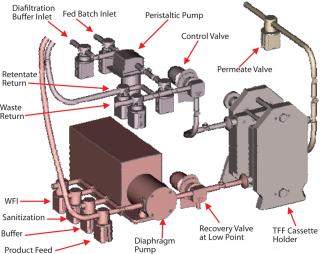

Photo 1:

System Design: A system designed specifically for incorporating single-use components is an essential requisite for a successful approach. Any restrictions in the capabilities of available components must be taken into account (e.g., pressure and flow limitations, sensor performance, and connectivity). We factored in critical process parameters such as hold-up volume, cross-flow velocity, and volume concentration factors (VCF). At the earliest possible stage, we also considered controllers and automation, especially their practical aspects such as ease of access to replaceable components and manifolds and turnaround time between batches.

The cassette holder and pumps are an essential part of the design. The central core of this TFF system (Figure 1) provides a platform on which five single-use manifolds could be attached to form a complete system. Figure 1 shows the cassette holder, pump drives, valve heads, and the various inlet and outlet flow paths. The design of this part of the system had to satisfy many requirements to ensure that the target performance could be achieved, but the following issues were particularly critical.

Pressures ≤3.5 bar (50 psig) on the product feed to the TFF cassette are essential to ensure sufficient transmembrane pressure (TMP) typically observed in traditional TFF operations. Such pressures cannot be reliably achieved with peristaltic pumps. Single-use systems restricted to TMPs of 1–1.7 bar (15–25psig) will require longer processing times and increased membrane area in cassettes.

We integrated a diaphragm pump with a single-use detachable head that could achieve the optimum TMP, thereby maximizing filter efficiency and minimizing process time and cassette size. On lower-pressure flow paths, peristaltic pumps met system requirements. The diaphragm pump has a working range of 30–1,200 L/h, which allows the system to support a 0.5 to 5-m2 filter membrane area. System line size can scale from 0.5 to 0.75 inches depending on TFF crossflow rate, which allows system optimization, minimum working volume, and fluid linear velocity for the full filter-area range.

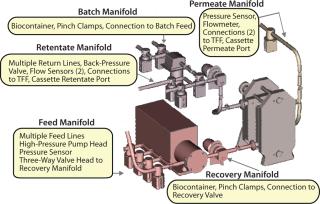

We designed the central core for ease of use and unrestricted access to the system. The design allows quick installation and removal of the various single-use manifolds. Five single-use manifolds are attached to the central core (Figure 2). Many factors had to be considered in designing them.

- Careful selection and assessment of construction materials, not only to meet flow and pressure requirements but to ensure that target performance and scalability requirements can be achieved

- Exclusive use of materials with full specification and certification for tubing sets

- Special attention on selection, attachment, and connectivity of sensors essential for process control.

The feed manifold has four low-pressure feed lines controlled by pinch valves to supply product, water for injection (WFI), buffer, and sanitizing fluids to the single-use high-pr

essure pump head. Downstream of the pump, braided silicone tubing is used for the feed to the single-use TFF cassette with an area ≤4 m2. An intermediate three-way valve enables connection to a manifold for final product recovery.

For the retentate manifold, precise control of backpressure is an essential requirement achieved by working with qualified component suppliers to obtain a single-use control valve with the required performance. The high-pressure side of the valve is fitted with braided tubing and a flow sensor. On the low-pressure side, pinch valves could open and close return lines.

The permeate manifold combines two permeate lines from the TFF cassette into a single flow path, which contains a pressure sensor, a flow meter, and pinch valves.

The batch manifold is the simplest of all five manifolds. It comprises a flexible biocontainer of the required volume and inlet/outlet tubing fitted with quick connectors. Fluid paths are opened and closed with pinch valves.

The recovery manifold is similar in design to the batch manifold and is used to maximize overall product recovery from the system following concentration and diafiltration.

Sensor Selection and Integration: Single-use instrumentation played a key role in this development program, offering the following benefits:

- Allows tracking of key process information

- Provides notification when processing is not within specification

- Enables automated control of processing to optimum conditions

- Facilitates fully automated process sequences.

To reach our decision on specific components, we assessed them on five specific criteria (Table 1). Instrument calibration and validation also was important because they minimize performance qualification studies and further calibration before use.

Table 1: Criteria for selection of single-use instrumentation

The pool of potential instruments for single-use applications is still relatively small. For downstream processing, instrument suppliers have focused on specific process analytical technologies (PATs) such as those for measuring temperature and pressure, whereas other technologies — such as those to evaluate flow — have received less attention. For the latter, extensive testing may be required and alternative methods of integration considered to maximize system performance.

We worked with a number of qualified suppliers with approved quality systems, good change control procedures, and compliant materials of construction to obtain the best possible technology and ensure that critical process parameters could be accurately monitored and controlled. We ensured that renewable costs, which have been a major limiting factor in introducing single-use sensors, were within a range users considered to be acceptable In this way, we established a high level of confidence that our system would achieve target performance and be comparable with a traditional cleanable system regarding concentration, diafiltration performance, and minimizing renewable processing costs.

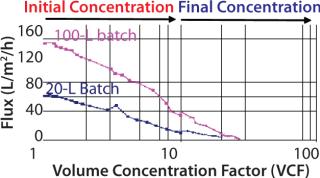

Operating Capabilities: We evaluated our single-use system using a protein solution and protocol typically found in bioprocessing (Figure 3). Two batches (20 and 100 L) were evaluated in suitably sized systems with identical flow paths and only slightly larger hold-up volume for the 100-L batch. To ensure sufficient mixing during diafiltration, we plumbed the buffer line directly into the retentate line before it returned to the biocontainer. Final processed concentrations of the two solutions were 200 g/L (for the 20-L batch) and 300 g/L (for the 100-L batch).

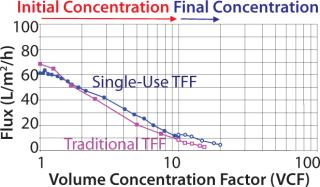

We measured flux (L/m2/h), volume concentration factor (VCF), conductivity (mS/cm), and diafiltration volumes. Figure 4 plots flux against VCF for both the initial and final concentration steps. Results show that for both batch sizes, target concentration factors were achieved during concentration. Moreover, a linear decrease in flux on a semilog scale agrees with the expected relationship and compares with a traditional TFF system.

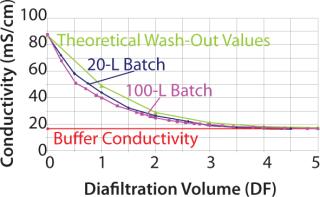

Figure 5 shows conductivity plotted against diafiltration volume (DF). The conductivity wash-out profile for both batch sizes was comparable to the theoretical wash-out curve.

Using those results, we concluded that the flux drop-off and diafiltration washout curves were comparable with those from a traditional stainless-steel TFF system. So we confirmed that the critical parameters could be monitored and controlled in a single-use system and the target performance achieved. Also, the curves confirmed that recirculation could achieve adequate mixing in the biocontainer without a more complex mixing system. The higher concentration trials represented a worst-case challenge to the mixing capability. Inadequate mixing would have prevented achievement of such high-concentration factors and result in significant membrane fouling and rapid decline in flux.

We compared these results with those from a previous stud

y on a traditional stainless-steel TFF system. In that trial, we processed a 20-L batch of polyclonal bovine IgG using a similar protocol of 10Ă— concentration followed by five buffer volumes diafiltration and final 2Ă— concentration. Flux, VCF, conductivity, and diafiltration volume were measured. In addition, we measured product recovery both after the initial gravity drain and after one recirculated buffer flush (Figure 6 and Table 2).

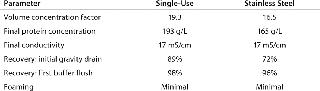

Table 2: Parameters measured in single-use and traditional TFF system trial

With those results, we concluded the following:

- Profiles of the flux versus VCF curves are the same for both systems.

- The single-use system’s VCF of 19.3 was slightly higher than the VCF from the stainless-steel system.

- Both systems achieved high final protein concentrations (>150 g/L), with a slightly higher value for the single-use system.

- Final conductivity values after diafiltration were similar (17 mS/cm) and in agreement with the theoretical washout performance.

- Both systems gave good product recovery after flushing (>96%), and the single-use system had higher recovery both after initial gravity drain (89%) and after first buffer flush (98%) (attributed to the design features and the low-point recovery drain).

- In both systems, foaming was minimal, which confirms that mixing by recirculation in the single-use system is an acceptable and effective procedure.

Automation: Manual TFF systems heavily depend on well-defined procedures and operator skills. Good manufacturing practice (GMP) requires detailed SOPs, training, and validation to limit any process variations. The regulatory position regarding operator interventions is clearly stated in GMP guidelines (1): “The design of equipment used in aseptic processing should limit the number and complexity of aseptic interventions by personnel ….”

Describing filtration, the guidelines also state: “…. liquid dosage forms are subject to filtration. Each of these manufacturing processes requires validation and control. Each process could introduce an error that ultimately could lead to the distribution of a contaminated product. Any manual or mechanical manipulation of the sterilized drug, components, containers, or closures prior to, or during aseptic assembly, poses the risk of contamination and thus necessitates control.”

The PAT initiative encourages wider use of enhanced technology to minimize operator error and improve accuracy and reliability of processes (2). This complements the direction of the GMP guidelines. To ensure conformance and minimize contamination risk, companies can use preassembled components, pre-irradiated assemblies, and automation. A successful approach to automation must focus at the earliest stage of development on a basic design. It is not possible simply to take a traditional system and make it from plastic materials. That would inevitably result in a system that is difficult to manage and limited in performance and reliability.

TFF VENDORs

— BPI Editors

The following companies are involved in tangential-flow filtration.

Pall Corporation (www.pall.com) products include the Cadence single-pass system, PallSep vibrating membrane filtration technology, and Kleepak capsules

Millipore (www.millipore.com) offers Mobius disposable TFF assemblies, the Cogent M1 TFF system, and Pellicon cassettes and modules

GE Healthcare (www.gelifesciences.com) cross-flow offerings include Unicorn automated control systems and Uniflex (pilot–production) and MidJet (laboratory) products

SciLog (www.scilog.com) offers the PureTec TFF system and a compact AccuTec manually controlled TFF unit

TangenX (www.tangenx.com) provides Sius disposable TFF cassettes and TFF membranes

One feature we designed into our automated system was ease of use. We also ensured that the system was designed and built in accordance with good engineering practice (GEP) and that necessary expertise and experience in systems engineering was available (3,4). We paid special attention to sensor selection and performance (a vital consideration when developing an automated system). The increasing availability of single-use sensors for critical parameters such as pressure, flow, temperature, and conductivity, has made automation possible for single-use TFF processes.

Taking into account those factors and working closely with component suppliers, we developed a prototype automated version of this single-use TFF system. Photo 1 shows key features of this system, including

- 20-L feed biocontainer

- 10-L recovery biocontainer

- 0.5–5 m2 TFF cassette

- single-use diaphragm pump

- 1,200 L/min maximum flow

- 0.5 and 0.75 inch tubing diameters

- 3.5-bar maximum pressure

- ~1-L working volume

- full automation.

We were aware that CMOs and other users of multiproduct systems considered fast turnaround between batches extremely beneficial because it helps reduce operating costs. Our system design emphasis on ease of use and careful consideration of a three-dimensional structure were essential ingredients to successful development. For example, incorporation of a “shadow board” design permitted full access to components from one side. Where possible, we implemented single-use sensors that were precalibrated and did not require recalibration before use, thereby minimizing downtime.

Our trials confirmed ease of use. Installation of manifolds, a cassette, and connections to peripheral supply such as product and buffers was achieved in ~10 min (range 6–11 min). Potential for automation was built into the design of the single-use feed manifold. It contains multiple feed lines to allow simple transfer from a manual to automated operation without having to rearrange the system before or during a process run.

Initial trials showed performance similar to that of traditional reusable systems. Further performance and application testing are in progress to provide necessary documentation and material certifications. The system has been designed for customization to meet specific user requirements. For some applications, a standard system may be suitable and would offer the benefit of lower manufacturing costs and expedited delivery.

Future Challenges

We met two major challenges in developing our single-use TFF system: performance comparable with that of a traditional TFF systems and a high level of automation. Availability of automated systems will undoubtedly drive wider application of single-use TFF. However, some further challenges of automation must be addressed to give additional benefits in the future, especially regarding scalability.

Flow Rates: Single-use, high-pressure pumps capable of flow rates from 1,200 L/h to 4,000 L/h are available, but cost may be a hindrance. Further developments in pump technology are likely to make higher flow rates possible at an acceptable cost and enhance the scalability of TFF systems.

Tubing Diameters: Our TFF system included flexible tubing with 0.5- and 0.75-in diameters. For larger cassette installations, the higher flow rates necessary to maintain cross-flow velocities generate linear velocities in 0.75-in tubing that exceed the maximum recommended of 2 m/s. Polymeric tubing with diameters ≥1-in is available, but the components for these diameters are substantially higher in cost because the quantities manufactured are relatively small. Some components may need to be custom-made and will have associated costs of machining or molding.

TFF Cassettes: Cassettes ≥5 m2 for single or multiuse are available, but their application are restricted by current limitations in flow capacity and tubing diameter. Developments of fully disposable cassette capsules are well advanced and will simplify processes, reduce capital costs, and provide greater flexibility on system size and scale-up.

Sensors and Instrumentation: For automating single-use TFF at current scales, sensors and instrumentation are available for most parameters, albeit limited in type and performance. If assessment in larger scale systems is a limitation, then alternative methods may be possible (e.g., flow rate using gravimetric methods or tachometers on displacement pumps). Present technology for measuring pH is significantly limited, and no cost-effective single-use device is available for measurement in the ultraviolet range.

Other Single-Use Technologies: For other upstream and downstream bioprocessing unit operations, single-use technology is either unavailable or in early stages of development. Areas where we might see significant progress are chromatography and depth filtration.

In chromatography, surface-modified adsorptive membranes have been introduced to replace resins in biopurification for applications such as DNA and HCP removal and protein adsorption/desorption (5). One main challenge for wider use of membrane chromatography systems is scale-up. However, recent developments have shown that these systems can be scalable using very innovative single-use designs.

For depth filtration, scalabilty, high solids capacity, and ease of use are key requirements. Large, high-pressure capsule systems show considerable promise, and recent studies indicate that they can not only replace existing stainless-steel filter systems, but also in some cases offer alternatives to other technologies such as centrifuges.

A Comparable TFF System

We designed and developed a single-use TFF system that could perform equal to or, for some parameters, better than a traditional stainless steel system. We automated the system by virtue of its basic design and with careful selection and evaluation of single-use instrumentation, resulting in low hold-up volumes and high product recoveries. Ease of use was a key feature achieved by incorporating rapid change-out manifolds and good access to the system.

Further work is now in progress to scale up the process for larger batches to enhance further the level of automation in terms of performance and reduced costs as well as to develop a range of stand-alone encapsulated cassettes for single-use TFF systems.

Author Details

Pauline Nicholson is product manager, single-use systems, 44-23-9230-3372, pauline_nicholson@europe.pall.com. Erik Storm is process engineer at Pall Life Sciences, 1-508-393-1800, erik_storm@pall.com.

REFERENCES

single use tff skid, depth filtration and virus filtration data sheet required