This webcast features: Andrew Lees, PhD, Founder and Scientific Director, Fina Biosolutions, LLC Tetanus toxoid (TT) is frequently used as a carrier protein for conjugate vaccines. TT contains strong T cell epitopes. They are toxoided protein and are not a uniform product because of specific toxoiding and purification processes. TT tends to aggregate with age and is not affordable to produce in quantities for research and early clinical work. TT heavy chain fragment C (rTTHc) is the C terminal fragment…

Webinars

Viral Vector Empty Versus Full and Plasmid Quantitation Analytics for Accelerated Gene Therapy Time to Market

This webcast features: Joe Ferraiolo, Associate Director, Bioanalytics Applications, C Technologies, a Repligen Company Analytical technologies play a crucial role in accelerating gene therapy speed to market. Dilution steps during protein and DNA quantitation measurements represent the single highest source of accuracy and precision errors. The SoloVPE® device provides a dilution-free workflow that saves time, reduces deviations, and facilitates multisite alignment. Multiple case studies from major biopharmaceutical companies describe execution in process development, analytical labs, and directly on good manufacturing…

Figure Out Any Particle with Automated Counting, Sizing, Morphology, and Identification Using the Hound

This webcast features: Lisa Krapf, Field Automation Scientist, Unchained Labs Thorough particle sizing and analysis are essential steps in formulation development and the monitoring of manufacturing process controls. Traditional particle analysis techniques such as light obscuration do not provide morphological information that can be useful for classification. Transfer to manufacturing and scaling to production will necessitate different equipment and the potential introduction of extrinsic particles that may not have been observed previously. The combination of particle analysis with flexible options…

Advantages of Custom Chromatography Resin Development: A Viable Solution for Purification of Complex Biotherapeutics

This webcast features: Scott Zobbi, Senior Manager of Business Development, Custom POROS Resins, Thermo Fisher Scientific Advances in biotherapeutic development are generating an increasing range of complex molecules, often presenting unique and complex purification challenges. Addressing these challenges requires novel purification strategies for commercial manufacturing, which may not always exist. When your specific process needs cannot be met with off-the-shelf resins, custom resin production may be a viable solution. Our POROS™ custom resin and CaptureSelect™ custom affinity matrix development platforms…

Protein or Not? Advanced High-Throughput Aggregate Analysis with the Aura™

This webcast features: Bernardo Cordovez, Chief Science Officer and Founder, Halo Labs In protein-based formulations, distinguishing aggregated active pharmaceutical ingredient (API) from other particle types is important for understanding the root cause of instability. Until now, existing methods have been either unreliable or too cumbersome to use in many workflows. Here we introduce the Aura™ 96-well low-volume aggregate and particle imaging system, which can rapidly size, count, and characterize particles and identify them as proteins, non-proteins, hydrophobic, or other types…

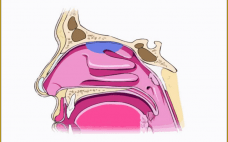

Translating Inhaled and Nasal Technologies for the Delivery of Biologics

This webcast features: Mark Parry, Technical Director, Intertek Inhaled and nasal delivery platforms have specific applications outside of their traditional uses for asthma/chronic obstructive pulmonary disease (COPD) and seasonal rhinitis/sinusitis: They can offer real advantages for the delivery of therapeutic biologics. During this short presentation, Intertek’s Technical Director, Mark Parry, will provide an overview of currently available technologies and successfully marketed products, with a look at the development challenges that might be encountered — and the solutions that are available…

Relative and Absolute Quantitation of Impurities and HCPs Using Mass Spectrometry

This webcast features: Steven Broome, Senior Mass Spectrometrist, BioPharmaSpec The processes involved in manufacturing a biopharmaceutical use biological and chemical systems to produce and purify the drug product. Therefore, the final active pharmaceutical ingredient (API) will often contain impurities related to these processes. It is a regulatory requirement to identify and monitor process-related impurities, and a qualitative and quantitative assessment of the components in the final drug product must be performed. Knowledge of the product-specific impurities, such as host-cell proteins…

2.5× Lentiviral Vector Bioreactor Yield Increase and Simplified Execution with Innovative Tangential-Flow Depth Filtration

This webcast features: Michael Bransby, R&D Director of Process Technology, Repligen In a joint collaboration, Oxford Biomedica and Repligen increased the yield of viral vectors from suspension-cultured bioreactors several fold using tangential-flow depth filtration (TFDF). The yield for a single clarification step was 95% as compared to 70% by standard depth filtration. The TFDF tubular format and low shear enabled further yield increases through multiple harvests from the same seeding. A single seeded bioreactor produced two harvests of 95% and…

Optimizing Your Excipient Screening for Vaccine Formulation with an Ultra-Pure Pharmaceutical Gelatin

This webcast features: Jeroen Geeraerts, Business Development Manager, Biomedical, Rousselot The world is working at an unprecedented pace to develop a safe and effective vaccine to combat the COVID-19 pandemic. Currently, five candidate vaccines are in clinical evaluation, and many more are in preclinical testing. Different types of vaccines are being developed using multiple strategies and platforms. Among them are several inactivated-virus and live-attenuated–virus candidate vaccines. As an excipient, gelatin is a key component in many vaccine formulations. Well-known examples…

Protein A Chromatography: Using Automation Instead of Multiple Columns To Increase Productivity

This webcast features: Van Leang, Senior Director of Global CMC Operations, HJB Bio Vendors supporting biologics manufacturing are developing equipment to enable continuous process in downstream operations. Using continuous downstream operations reduces operational time and raw material costs. HJB has developed a downstream hybrid process that uses an automated batch approach to achieve a continuous downstream capture process. This allows the use of the current monoclonal antibody (MAb) capture platform but reduces cost overall by adopting the benefits of continuous…