Mathematically modeling the kinetics of batch and continuous cultivation allows you to not only calculate and evaluate the effects of process parameters, but also to forecast those parameters and duration of cultivation to develop a cost-effective production process. Mathematical modeling microorganism cultivation was intensively developed in the second half of the last century. Equations 1–6: () Monod proposed Equation 1 for batch processes in 1942 (1). In that equation, µ and µmax are the specific and maximum…

Upstream Processing

Novel Single-Use Sensors for Online Measurement of Glucose

According to an FDA guidance document, process analytical technology (PAT) tools “are intended to support innovation and efficiency in pharmaceutical development” (1). The agency encourages manufacturers to use a PAT framework for developing and implementing effective innovative approaches in development, manufacturing, and quality assurance. The sensors described here are one possible response to the requirement of systems by analyzing and controlling critical cultivation parameters with real-time process measurements. Working Principle Glucose was measured using a #CITSens…

How an Obscure Asian Rodent Took Over Biotechnology

The earliest domestic rodents were cavies (“Guinea pigs”) kept as food animals in the Andes since 5000 BC (as shown by mummified cavies) and carried to Europe in the 16th century (Elizabeth I had one as a pet). Although rats weren’t domesticated until the mid-19th century (a byproduct of the blood sport of rat-baiting), mouse selection and breeding began many centuries earlier. Selection of unusually colored mice was first documented ~1100 BC in China, and breeding such “fancy” mice as…

Economic Impact of Single-Use Bioreactors

In order to match the improved titers and yield Innovation has provided, many biopharmaceutical companies are re-evaluating the operational costs of stainless steel and exploring the economics of single-use systems.

ROUNDTABLE – Single-Use Technologies: Industrialization, Standardization, Regulation – Common Goals and Differing Expectations

As the adoption and maturation of single-use technologies continues to evolve, many end-users are looking for single-use suppliers to standardize products, materials, and equipment in order to improve efficiency and lower costs. An expert group of industry suppliers discusses the pros/cons and differing expectation surrounding this trend.

Using the XS Toolbox to Optimize Strain Design and Development for Efficient Microbial GMP Production

No single strain or vector is capable of being the best expression option for all types of biopharmaceuticals. The XS System™ ultimately decreases the time of strain screening and design to enable the fast creation of a valuable production strain and efficient cGMP process.

A Decade of Animal Cell Culture

Eukaryotic cells are fragile and finicky, requiring very specific culture conditions and nutrients to survive, grow, and be productive in an ex vivo environment. Even so, they have become vital to the biopharmaceutical industry’s ability to make complex biological products — overtaking yeast as a production system around 1990 and surpassing bacteria in the number of associated product approvals five years later (1). Since then, they have become even more useful, expanding their reach into the vaccine world. Mammalian cell…

A Decade of Microbial Fermentation

Microorganisms play a vital role in modern life — with applications ranging from wine fermentation to biofuel production to solutions for complex mathematical problems (1). During the past decade, microbial fermentation for protein production reached a higher level of sophistication and wider adoption. When BPI was first published in 2003, the physical and biological characteristics of many microbial cells and the attributes of their fermentation processes were well known. Nonetheless, the economic environment at that time created immense pressure on…

Bioreactor Design and Bioprocess Controls for Industrialized Cell Processing

It’s official: The “Age of Cell Therapy” has arrived. A robust pipeline of cell therapies, with increasing numbers of both early- and late-stage clinical trials as well as FDA-approved commercial products that have entered the market already, strongly indicates that the cell therapy industry is poised to emerge as a distinct healthcare sector (1). Renewed investor interest and recent activity among major pharmaceutical companies suggest that this industry will rapidly develop the capability and capacity to be a highly competitive,…

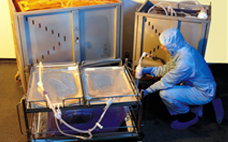

A Decade of Bioreactor and Upstream Technologies

A high-quality product begins with efficient upstream process equipment. Ten years ago, manufacturers were still warming up to single-use bioreactors, which were mainly rocking-bag–based solutions. The benefits relating to cleaning and validation were clear, but their use as bioreactor vessels was still new, and stainless steel systems up to 20,000 L in scale were still needed. Today’s facilities are a hybrid of sophisticated single-use components and stainless steel equipment, the mechanisms of both having undergone improvement during the past decade.…